A bell-shaped laser intensity distribution is preferred for growing certain oxide crystals because it softens the temperature gradient along the growth axis. Unlike a flat distribution that creates sharp thermal transitions, a bell-shaped profile spreads the heat more vertically, significantly reducing the risk of the material cracking during the process.

While steep temperature gradients are excellent for stabilizing a molten zone, they frequently cause materials with low thermal conductivity to shatter. A bell-shaped distribution acts as a thermal buffer, creating an "in-situ annealing" effect that relieves internal stress and preserves the single crystal's structure.

The Challenge: Thermal Stress in Oxides

Low Thermal Conductivity

Many oxide materials are poor conductors of heat. This physical property makes them highly susceptible to internal thermal stress.

When heat is applied or removed too quickly, the temperature difference between the core and the surface of the material becomes extreme. Because the material cannot transfer heat fast enough to equalize the temperature, massive tension builds up within the crystal lattice.

The Danger of Narrow High-Temperature Zones

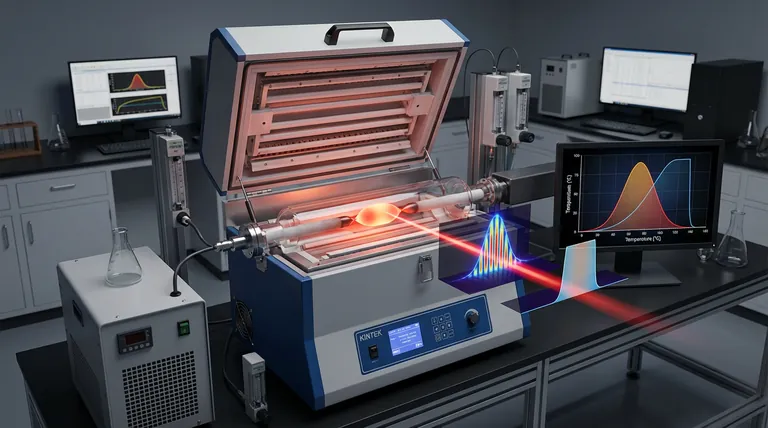

In laser Floating-Zone (LFZ) systems, a flat laser distribution creates a highly concentrated, narrow zone of intense heat.

While this creates a very steep temperature gradient, which is technically useful for holding a molten zone in place, it creates a "thermal shock" environment. For sensitive oxides, this narrow zone is often too abrupt, leading to immediate fracture or cracking during the cooling phase.

The Solution: Vertical Bell-Shaped Modulation

Softening the Gradient

By modulating the laser intensity into a vertical bell-shaped distribution, the system alters how heat is delivered to the sample.

Instead of a "square wave" of heat (on/off), the bell shape provides a gradual ramp-up and ramp-down of intensity. This results in a temperature gradient that is far more gradual, extending the length of the heated zone slightly without overheating the melt.

In-Situ Annealing

The primary benefit of this softer gradient is an in-situ annealing effect.

As the newly formed crystal moves out of the molten zone, the "tail" of the bell-shaped distribution keeps it warm, allowing it to cool down slowly. This controlled cooling process allows the crystal lattice to settle without accumulating the destructive stress associated with rapid freezing.

Understanding the Trade-offs

Stability vs. Integrity

It is important to recognize why flat distributions are used in other contexts. Steep temperature gradients provide superior stability for the molten zone, preventing it from dripping or collapsing due to gravity or surface tension issues.

However, when working with oxides, you are trading a small amount of zone stability for structural integrity. The bell-shaped distribution sacrifices the "tightness" of the molten zone to ensure the material survives the process intact.

Making the Right Choice for Your Growth Process

To determine the best laser distribution for your specific application, consider the material's thermal properties:

- If your primary focus is growing crack-free oxides: Prioritize a bell-shaped distribution to lower thermal gradients and induce in-situ annealing.

- If your primary focus is stabilizing a highly fluid melt: Consider a flatter or sharper distribution, provided the material has high thermal conductivity and can withstand the stress.

Success in growing complex oxides requires balancing the physics of the molten zone with the thermal limits of the solid crystal.

Summary Table:

| Feature | Flat Distribution | Bell-Shaped Distribution |

|---|---|---|

| Temperature Gradient | Steep and sharp | Soft and gradual |

| Heated Zone Length | Narrow / Concentrated | Extended / Tapered |

| Material Stress | High (Thermal Shock) | Low (Stress Relief) |

| Cooling Effect | Rapid freezing | In-situ annealing |

| Primary Benefit | Molten zone stability | Structural crystal integrity |

| Best Use Case | Highly conductive materials | Low-conductivity oxides |

Achieve Perfect Crystal Growth with KINTEK

Don't let thermal stress compromise your research. Backed by expert R&D and manufacturing, KINTEK provides advanced laser Floating-Zone (LFZ) technology and high-temp systems designed specifically to handle the complexities of sensitive oxide crystals. Whether you require a Muffle, Tube, Rotary, Vacuum, or CVD system, our furnaces are fully customizable to your unique thermal profile requirements.

Ready to eliminate material cracking and optimize your growth process? Contact our specialists today to find your custom solution!

References

- Naoki Kikugawa. Recent Progress of Floating-Zone Techniques for Bulk Single-Crystal Growth. DOI: 10.3390/cryst14060552

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What are the key benefits of vacuum brazing? Achieve Strong, Clean Joints for Complex Assemblies

- How do graphite heating elements function in vacuum furnaces? Unlocking Extreme Heat for Critical Processes

- What role does a vacuum sintering furnace play in fine ceramic component production? Achieve High-Purity, Dense Ceramics

- Why is a vacuum furnace beneficial for applications requiring high purity? Achieve Unmatched Material Purity and Performance

- How does heat loss occur in vacuum furnace insulation? Two Pathways Draining Efficiency

- What critical conditions do a vacuum sintering furnace provide for SiCf/Al-Mg? Optimize Your Composite Solidification

- What is the function of a vacuum austenitizing furnace for SCM440 steel? Achieve Precision Heat Treatment