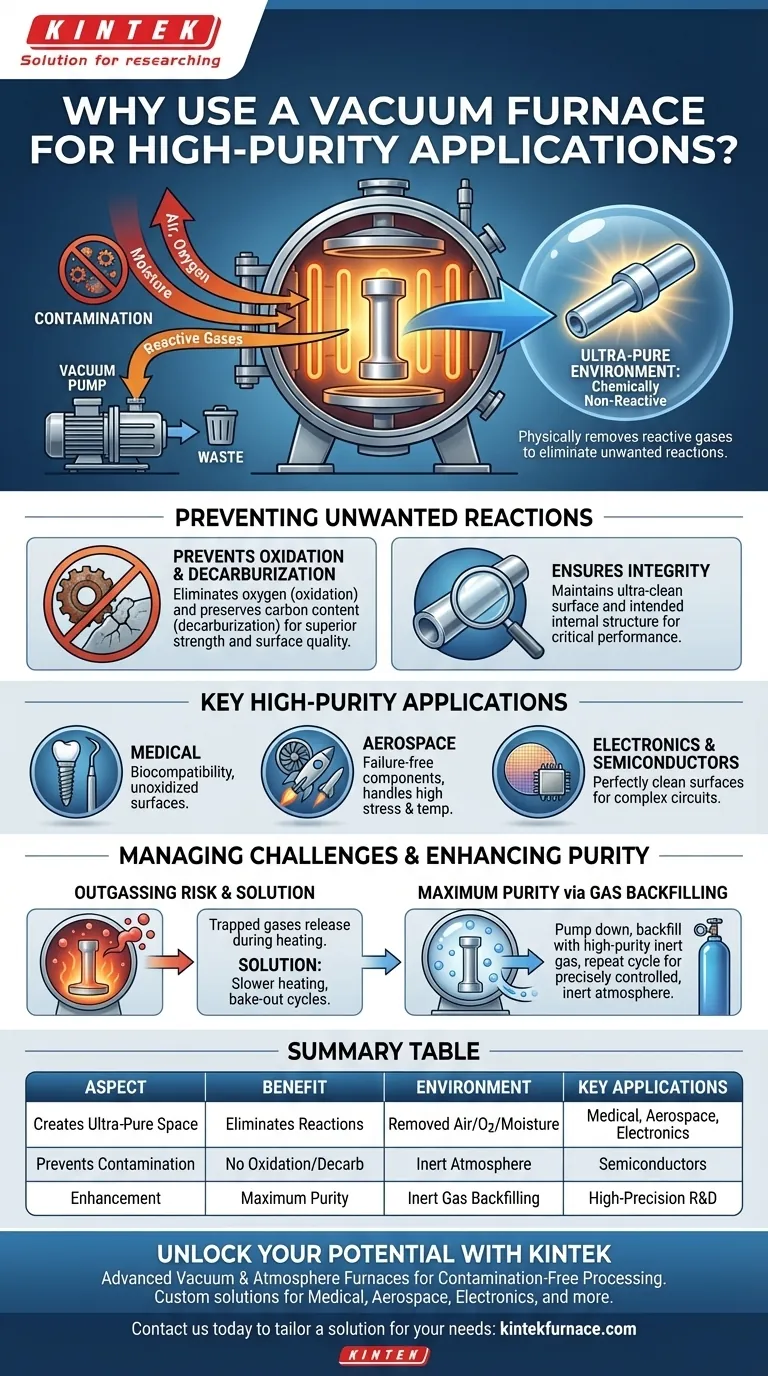

In essence, a vacuum furnace creates an ultra-pure environment by physically removing the reactive gases that cause contamination. By pumping out air, oxygen, and moisture before heating, it eliminates the root cause of unwanted chemical reactions, ensuring the final material is structurally and chemically pristine.

By removing the atmosphere, you remove the source of contamination. A vacuum furnace isn't just about heat; it's about providing a controlled, inert space where high temperatures can modify a material without introducing impurities like oxides.

The Core Principle: Eliminating Unwanted Reactions

The primary benefit of a vacuum furnace is its ability to create a chemically non-reactive environment. This prevents high-temperature processes from degrading the material being treated.

Removing Primary Contaminants

The first step in any vacuum furnace process is drawing a vacuum. This action removes the most common contaminants from the chamber: air, moisture, and other reactive gases.

Without this step, these elements would readily react with the hot material, fundamentally altering its properties.

Preventing Oxidation and Decarburization

Oxidation is the most common form of contamination, where oxygen reacts with a metal's surface to form a brittle oxide layer. A vacuum environment is inherently oxygen-free, preventing this entirely.

Similarly, decarburization, the loss of carbon content from steel's surface, is avoided. This is critical for maintaining the hardness and fatigue life of high-strength alloys.

Ensuring Surface and Structural Integrity

By preventing these unwanted reactions, the furnace ensures the final product has an ultra-clean surface and maintains its intended internal structure.

This is non-negotiable for applications where surface quality or chemical purity directly impacts performance, such as medical implants or semiconductor wafers.

Key Applications Driven by Purity

The benefits of vacuum processing are most evident in industries with zero tolerance for material failure or contamination.

Medical and Aerospace

For medical implants, a pure, unoxidized surface is essential for biocompatibility and preventing rejection by the body.

In aerospace, components like turbine blades must be free of surface impurities that could become stress points and lead to catastrophic failure at high temperatures and pressures.

Electronics and Semiconductors

The manufacturing of semiconductors and advanced electronics relies on perfectly clean surfaces. Even microscopic contamination can ruin complex circuits, making vacuum processing a standard requirement.

Understanding the Trade-offs and Challenges

While powerful, vacuum furnaces are not without their complexities. Acknowledging these is key to successful implementation.

The Risk of Outgassing

Outgassing is a phenomenon where gases trapped within the material itself are released into the vacuum as the part heats up. These released gases can then contaminate the part's surface.

Careful process control, including slower heating rates or preliminary "bake-out" cycles, is often required to manage this effect.

Operational and Material Limitations

Vacuum pumps require more frequent and specialized maintenance than standard atmosphere furnace systems.

Cooling can also be slower, as there are fewer gas molecules to transfer heat away from the part. Additionally, some materials can suffer from sublimation (turning from a solid directly to a gas) under a deep vacuum.

Enhancing Purity with Gas Backfilling

For the highest level of purity, a common technique is to pump the chamber down to a vacuum and then backfill it with a high-purity inert gas, such as argon or nitrogen.

Repeating this pump-and-purge cycle multiple times can further dilute and remove any residual reactive gases, creating a precisely controlled, inert atmosphere.

Making the Right Choice for Your Process

Selecting the right thermal process depends entirely on your material and end-goal.

- If your primary focus is preventing surface oxidation: A vacuum furnace offers the most reliable way to create a completely oxygen-free environment for treating sensitive metals.

- If your primary focus is achieving maximum material purity: Use a deep vacuum combined with multiple inert gas purge cycles to remove both atmospheric and trapped contaminants.

- If you are dealing with materials prone to outgassing: Plan for a slower pump-down or a preliminary bake-out cycle to manage contamination coming from the material itself.

Ultimately, a vacuum furnace gives you an unparalleled level of control over the processing environment, enabling you to achieve material properties that are simply not possible otherwise.

Summary Table:

| Aspect | Benefit |

|---|---|

| Environment | Creates ultra-pure, inert space by removing air, oxygen, and moisture |

| Prevents Contamination | Eliminates oxidation, decarburization, and unwanted chemical reactions |

| Key Applications | Medical implants, aerospace components, semiconductors, and electronics |

| Challenges | Outgassing risks, slower cooling, and maintenance requirements |

| Enhancement | Use of inert gas backfilling for maximum purity |

Unlock the Full Potential of Your High-Purity Applications with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in medical, aerospace, or electronics, our vacuum furnaces ensure contamination-free processing for superior results.

Contact us today to discuss how we can tailor a solution for your specific needs and enhance your material purity and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures