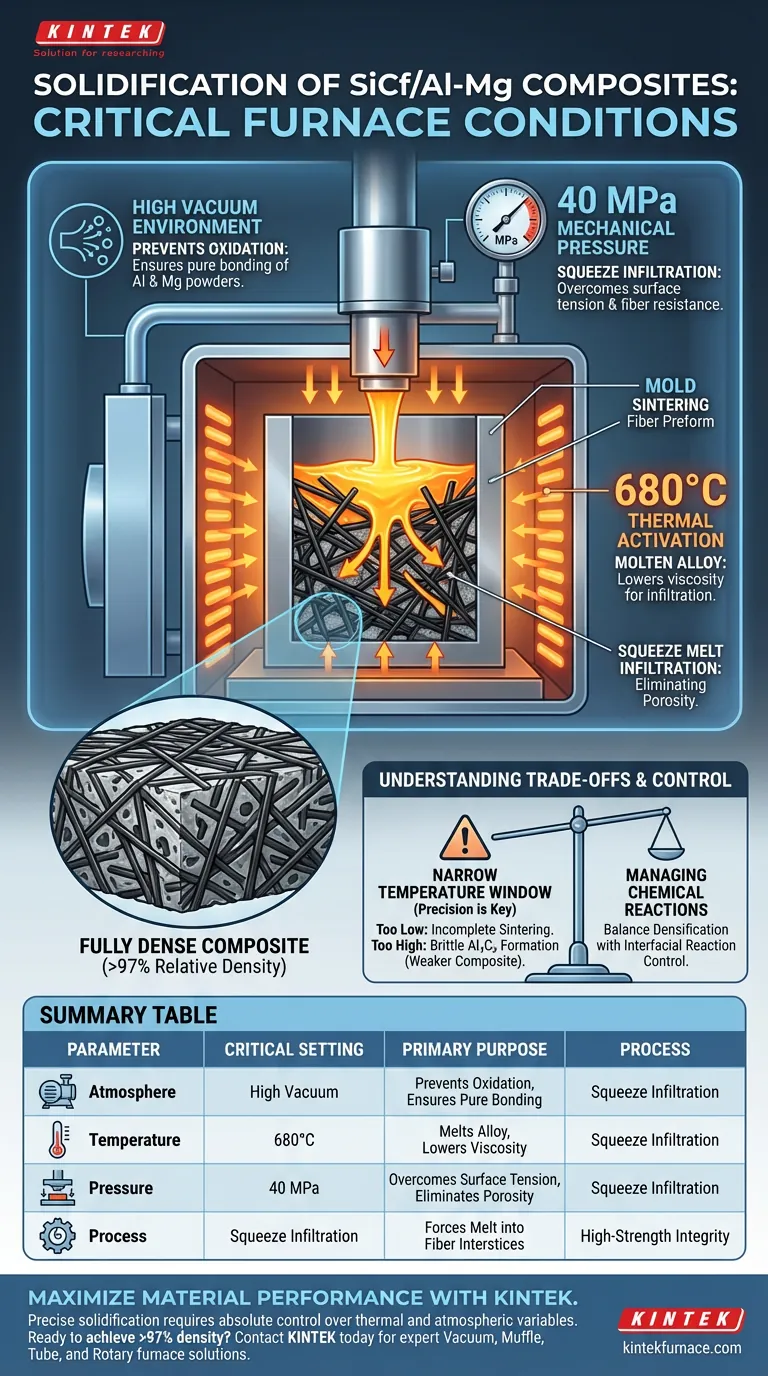

A vacuum sintering furnace functions as a high-precision reaction chamber. To ensure successful solidification of SiCf/Al-Mg composites, the system creates a vacuum environment to prevent oxidation and heats the material to 680°C. Simultaneously, the associated molds—coupled with an external pressing device—apply a constant mechanical pressure of 40 MPa to force the molten alloy into the reinforcement fibers.

The core objective of this setup is squeeze melt infiltration. By synchronizing high heat (680°C) with significant mechanical pressure (40 MPa) in a vacuum, the system forces the aluminum-magnesium melt into the deepest fiber interstices, effectively eliminating porosity and achieving a relative density exceeding 97%.

Creating the Ideal Environment for Solidification

To achieve a high-performance composite, the furnace must control the atmosphere and thermal energy with extreme precision.

The Critical Role of Vacuum

The primary function of the vacuum environment is the prevention of oxidation. Aluminum and magnesium powders are highly reactive; without a vacuum, they would rapidly oxidize during heating. The vacuum ensures the metal powders remain pure, preventing the formation of oxide layers that would inhibit bonding.

Thermal Activation at 680°C

The furnace must achieve and maintain a specific temperature of 680°C. At this temperature, the aluminum-magnesium alloy becomes molten, lowering its viscosity sufficiently to flow through the fiber reinforcement. This thermal state is the prerequisite for the infiltration process.

The Mechanics of Densification

Heat and vacuum alone are often insufficient to fully densify a fiber-reinforced composite. The molds and mechanical pressure provide the necessary physical force.

High-Pressure Infiltration

The associated molds utilize an external pressing device to exert 40 MPa of pressure. This is not a passive casting process; it is an active injection. The pressure overcomes the surface tension of the melt and the resistance of the fiber network.

Eliminating Porosity

The combination of pressure and the liquid state allows the melt to penetrate the fiber interstices (the small gaps between fibers). This "squeeze" action drives out voids and fills gaps that gravity alone could not reach, resulting in a nearly fully dense material.

Understanding the Trade-offs

While high temperature and pressure are required for density, they introduce process sensitivities that must be managed carefully to avoid degrading the material.

The Narrow Temperature Window

Precise temperature control is essential. While 680°C is required for infiltration in this specific process, deviations can be detrimental. If the temperature is too low, sintering remains incomplete and porosity persists.

Managing Chemical Reactions

There is a risk associated with high temperatures and prolonged holding times. Excessive heat or duration can lead to the formation of brittle aluminum carbide (Al4C3) at the interface. This creates a trade-off: you need heat for flow, but too much heat creates brittle phases that weaken the composite. The process must balance densification with the control of interfacial chemical reactions.

Making the Right Choice for Your Goal

The specific parameters you prioritize in the furnace cycle will dictate the final properties of your composite.

- If your primary focus is Structural Integrity: Prioritize maintaining the full 40 MPa pressure throughout the solidification phase to ensure the relative density stays above 97%.

- If your primary focus is Thermal/Electrical Conductivity: Focus on precise temperature regulation, ensuring the heat is sufficient for bonding but strictly controlled to prevent the formation of resistive brittle phases.

Success depends on the synchronized application of thermal energy and mechanical force within a protected vacuum environment.

Summary Table:

| Parameter | Critical Setting | Primary Purpose |

|---|---|---|

| Atmosphere | High Vacuum | Prevents oxidation of Al-Mg powders and ensures pure bonding. |

| Temperature | 680°C | Melts the alloy and lowers viscosity for infiltration into fiber gaps. |

| Pressure | 40 MPa | Overcomes surface tension to eliminate porosity and achieve >97% density. |

| Process | Squeeze Infiltration | Forces melt into fiber interstices to create high-strength structural integrity. |

Maximize Your Material Performance with KINTEK

Precise solidification of advanced composites like SiCf/Al-Mg requires absolute control over thermal and atmospheric variables. KINTEK provides industry-leading vacuum, muffle, and customizable high-temperature furnace systems engineered for rigorous R&D and manufacturing requirements.

Whether you need specialized Vacuum or CVD systems for squeeze infiltration or tailored Tube and Rotary furnaces for material processing, our expert R&D team is ready to design a solution for your unique needs.

Ready to achieve >97% relative density in your materials? Contact KINTEK today to discuss your project requirements.

Visual Guide

References

- Guanzhang Lin, Zhaozhao Lv. Strengthening Mechanism and Damping Properties of SiCf/Al-Mg Composites Prepared by Combining Colloidal Dispersion with a Squeeze Melt Infiltration Process. DOI: 10.3390/ma17071600

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the key properties of vacuum brazed connections? Achieve Strong, Clean, and Hermetic Joints

- What types of heat treatment processes can a vacuum furnace support? Achieve Purity and Precision in Material Processing

- How does the sintering process work? Master the Art of Powder-to-Solid Transformation

- What are the advantages of using a Vacuum Spark Plasma Sintering (SPS) system over traditional furnaces for TiB2-SiC?

- What are the advantages of using graphite as a heating element in vacuum furnaces? Achieve Extreme Heat with Superior Stability

- What gases are used in vacuum quenching and for which materials? Optimize Your Heat Treatment with Precision

- Why is degasification in a vacuum oven necessary for BET analysis? Ensure Accuracy in Activated Carbon Measurements

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C