Accurate BET analysis relies on a clean slate. Degasification in a vacuum oven is necessary to strip away moisture, air, and volatile impurities commonly trapped within activated carbon. Without this step, these pre-existing contaminants occupy the material's pores, physically blocking the analysis gas (usually nitrogen) and leading to significantly skewed measurement data.

Activated carbon is highly absorbent by nature, meaning its pores are rarely empty in ambient conditions. Vacuum degasification removes these "guest" molecules to ensure the subsequent BET measurement reflects the carbon's true physical structure, rather than just the empty space currently available.

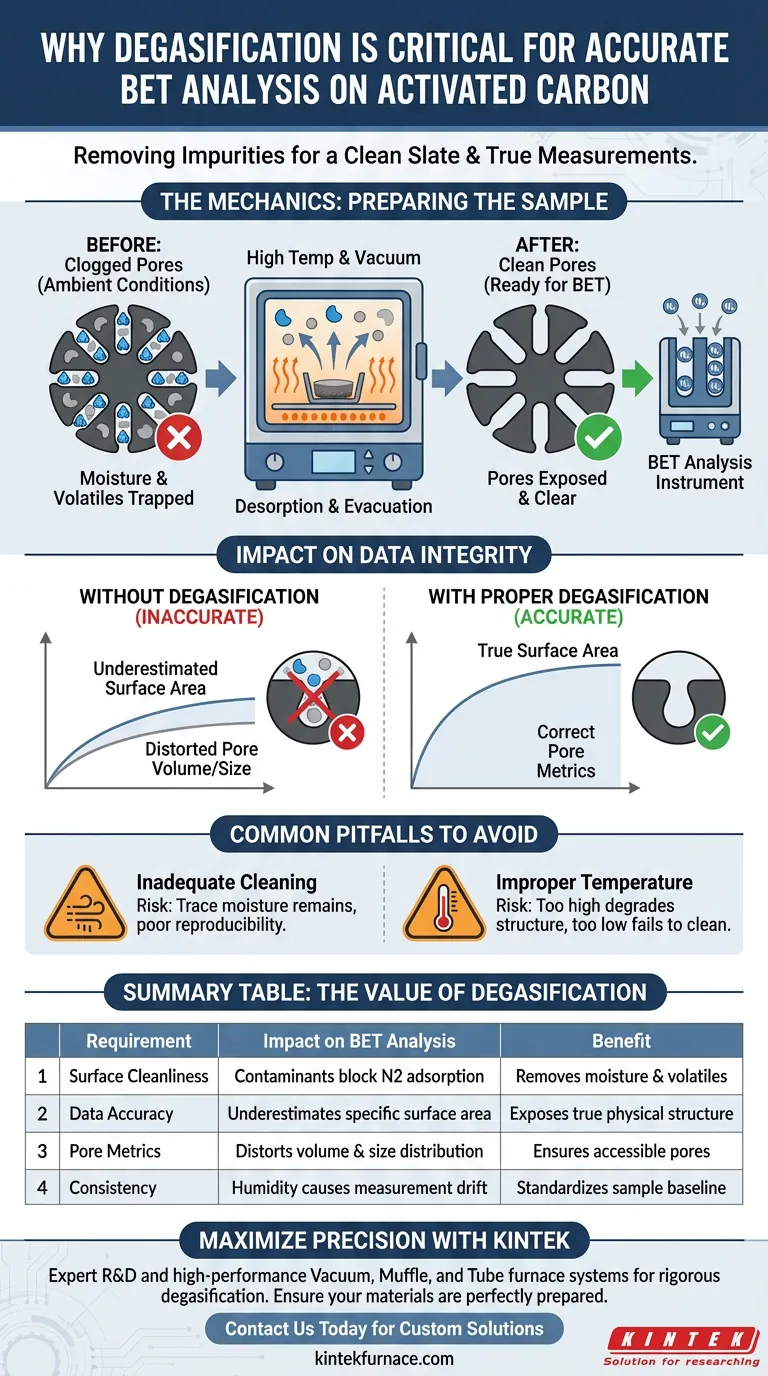

The Mechanics of Preparation

To understand why this step is non-negotiable, you must look at the microscopic interaction between the sample and the environment.

Removing Adsorbed Impurities

Activated carbon possesses a complex network of pores that naturally adsorb moisture and gases from the surrounding air.

These "impurities" settle deep within the pore structure. A vacuum oven utilizes high temperatures combined with a vacuum environment to force these volatiles to desorb and evacuate the sample.

Exposing the Analysis Sites

The goal of BET analysis is to cover the surface of the carbon with nitrogen molecules.

If the surface is already covered by water vapor or trace volatiles, the nitrogen cannot latch onto the carbon. Degasification clears these sites, ensuring they are fully exposed for the probe gas to measure.

Impact on Measurement Data

Skipping or rushing the degasification process does not just lower the quality of your data; it fundamentally invalidates it.

Specific Surface Area Errors

BET theory calculates surface area based on how much gas attaches to the solid.

If pores are blocked by contaminants, the instrument detects less surface area than actually exists. This leads to an underestimation of the material's capability.

Distorted Pore Metrics

Beyond surface area, analysts look for total pore volume and pore size distribution.

Blocked pores appear to the instrument as if they do not exist. Consequently, the analysis will report a lower total pore volume and an inaccurate distribution of pore sizes.

Common Pitfalls to Avoid

While degasification is critical, the process requires careful management to avoid introducing new errors.

The Risk of Inadequate Cleaning

"Adequate" is the operative word. If the vacuum level is too weak or the duration too short, trace moisture remains.

This results in poor reproducibility, where the same sample yields different results on different days depending on humidity levels.

Balancing Temperature Limits

The primary reference notes the use of "high-temperature" conditions. However, there is a trade-off.

You must ensure the temperature is high enough to remove volatiles but not so high that it degrades or alters the activated carbon structure itself.

Ensuring Data Integrity in Your Analysis

To derive value from BET measurements, you must treat sample preparation with the same rigor as the analysis itself.

- If your primary focus is absolute accuracy: Ensure the degasification protocol is aggressive enough to completely remove deep-seated moisture without damaging the sample matrix.

- If your primary focus is process consistency: Standardize the vacuum oven settings (time and temperature) strictly across all batches to prevent preparation variables from skewing your comparison data.

Treat degasification not as a preliminary chore, but as the fundamental baseline required for valid material characterization.

Summary Table:

| Requirement | Impact on BET Analysis | Benefit of Vacuum Degasification |

|---|---|---|

| Surface Cleanliness | Contaminants block nitrogen adsorption | Removes moisture and volatiles from pores |

| Data Accuracy | Underestimates specific surface area | Exposes true physical structure for measurement |

| Pore Metrics | Distorts volume and size distribution | Ensures all pores are accessible to probe gas |

| Consistency | High humidity causes measurement drift | Standardizes sample baseline for reproducibility |

Maximize Your Material Characterization Precision with KINTEK

Don't let sample preparation errors compromise your research data. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, and Tube furnace systems specifically designed for rigorous degasification and thermal processing. Our customizable solutions ensure your activated carbon and advanced materials are perfectly prepared for BET analysis every time.

Ready to elevate your lab's accuracy? Contact us today to find your custom furnace solution!

Visual Guide

References

- Dzilal Amir, Nurul Sakinah Engliman. Investigating the synthesis parameters of durian skin-based activated carbon and the effects of silver nanocatalysts on its recyclability in methylene blue removal. DOI: 10.1186/s11671-024-03974-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the core functions of dual-chamber vacuum heat treatment systems? Master Precision Gas Quenching

- What modular features enhance vacuum furnace flexibility? Boost Efficiency with Scalable, Quick-Change Designs

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- Why is a vacuum drying oven set to 70 °C for g-C3N4/Bi2WO6? Optimize Your Photocatalyst Post-Processing

- What role does a high-temperature vacuum furnace play in sintering magnesium composites? Key Success Factors

- Why must Ge-S-Cd alloy tablets be placed in vacuum-sealed capsules? Ensure High-Purity Chalcogenide Synthesis

- Why are vacuum furnaces essential for titanium alloy? Protect Your Components from Embrittlement

- What applications does a vacuum melting furnace have in research? Unlock High-Purity Material Development