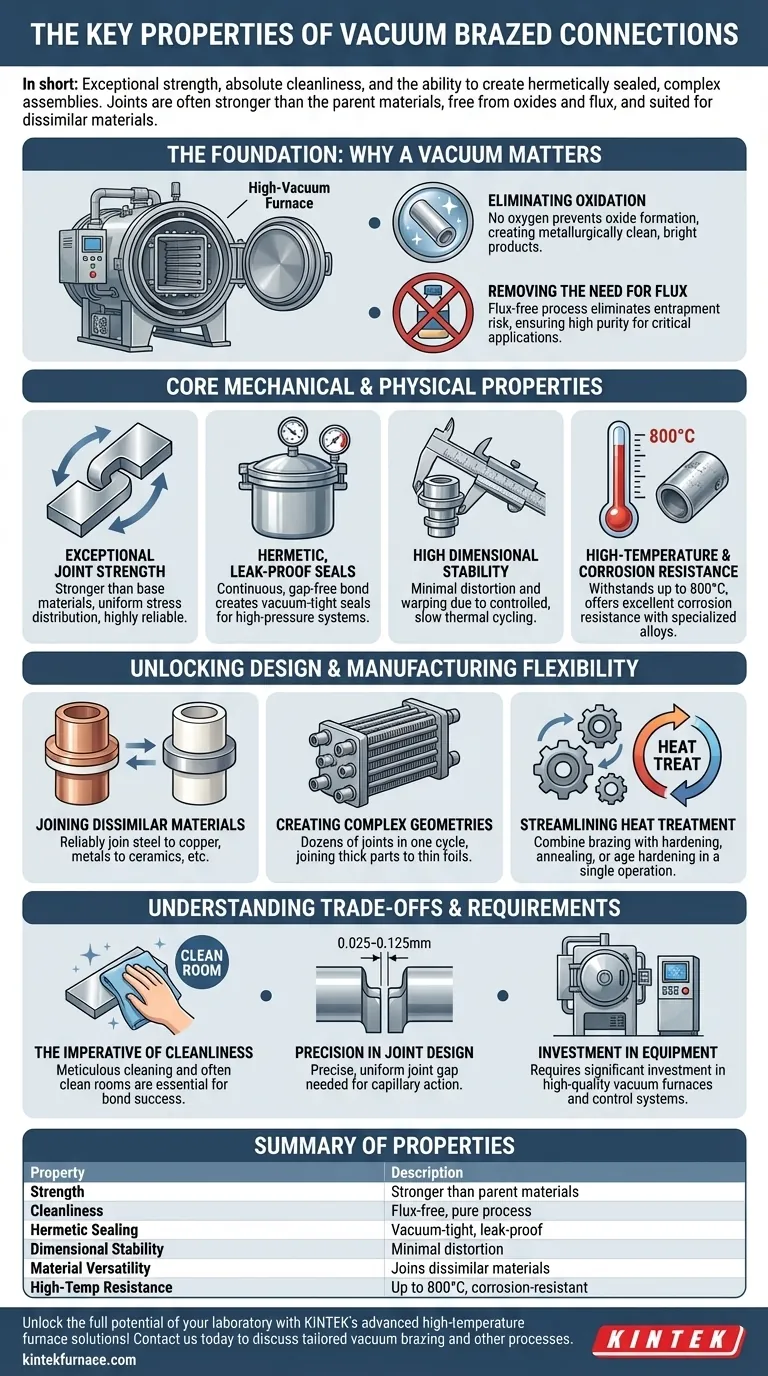

In short, vacuum brazed connections are defined by their exceptional strength, absolute cleanliness, and the ability to create hermetically sealed, complex assemblies. The process produces joints that are often stronger than the parent materials themselves, free from oxides and flux residues, and perfectly suited for joining dissimilar materials like metal to ceramic.

Vacuum brazing is not merely a joining technique; it is a high-precision manufacturing process. By removing the atmosphere, it allows a filler metal to form a metallurgical bond that transforms separate components into a single, monolithic, high-performance part.

The Foundation: Why a Vacuum Matters

The defining characteristics of vacuum brazing all stem from its core principle: removing reactive gases, primarily oxygen, from the environment during the joining process.

Eliminating Oxidation and Contamination

In a high-vacuum furnace, there is no oxygen to react with the metal surfaces at elevated temperatures. This prevents the formation of oxides that can weaken a joint and compromise its integrity.

The result is a metallurgically clean, bright, and shiny finished product that requires no post-process cleaning to remove scale or discoloration.

Removing the Need for Flux

Traditional brazing requires a chemical flux to clean the surfaces and prevent oxidation. This flux can become trapped in the joint, leading to corrosion or failure points later in the product's life.

Vacuum brazing is a flux-free process. This complete absence of flux eliminates the risk of entrapment and ensures the highest possible purity and hygiene, which is critical for medical, food-grade, and semiconductor applications.

Core Mechanical and Physical Properties

The controlled vacuum environment enables a unique set of physical properties that are difficult to achieve with other joining methods.

Exceptional Joint Strength

Properly designed vacuum brazed joints are as strong or stronger than the base materials being joined. The filler metal forms a diffuse, permanent metallurgical bond with the parent materials.

This creates a highly reproducible and reliable connection that distributes stress evenly, unlike the localized stress points common in welding.

Hermetic, Leak-Proof Seals

The capillary action of the molten filler metal completely fills the gap between the components, creating a continuous, gap-free bond.

This results in vacuum-tight, hermetically sealed joints capable of holding pressure or vacuum without leaking, essential for aerospace, scientific instruments, and high-pressure systems.

High Dimensional Stability

The process uses slow, uniform heating and controlled cooling cycles within the furnace. This minimizes thermal stress across the entire assembly.

The result is minimal distortion, warping, or residual stress, making it the ideal choice for joining precision-machined components with tight tolerances.

High-Temperature and Corrosion Resistance

The properties of the joint are largely determined by the chosen filler metal. Using precious or specialized nickel-based filler alloys, vacuum brazed connections can withstand service temperatures up to 800°C.

These alloys also provide excellent corrosion resistance, matching or exceeding that of the parent materials.

Unlocking Design and Manufacturing Flexibility

Vacuum brazing removes many constraints found in conventional manufacturing, opening the door for more innovative and efficient product designs.

Joining Dissimilar Materials

One of the most significant advantages is the ability to reliably join materials with different properties, such as steel to copper or metals to ceramics.

This is notoriously difficult or impossible with fusion welding, but vacuum brazing makes it a routine and highly reliable process.

Creating Complex Geometries

An entire assembly with dozens or even hundreds of joints can be made in a single furnace cycle.

It also allows for joining very thick parts to very thin foils or large surface areas, giving engineers tremendous design freedom for creating complex products like heat exchangers or sensor assemblies.

Streamlining Heat Treatment

Because the process takes place in a high-temperature furnace, it is possible to combine the brazing cycle with other heat-treatment processes like hardening, annealing, or age hardening.

This consolidation saves significant time, energy, and cost by completing multiple manufacturing steps in a single, controlled operation.

Understanding the Trade-offs and Requirements

While powerful, vacuum brazing is a process that demands precision. Its benefits are only realized when its fundamental requirements are met.

The Imperative of Cleanliness

The success of the process is absolutely dependent on the cleanliness of the components. Any oils, greases, or surface contaminants will vaporize in the vacuum and interfere with the metallurgical bond.

This necessitates meticulous pre-cleaning procedures and often requires the use of clean rooms for assembly.

Precision in Joint Design

The process relies on capillary action to draw the molten filler metal into the joint. This requires a precise, uniform gap between the parts, typically between 0.025 mm and 0.125 mm (0.001" to 0.005").

Incorrect joint clearance will result in an incomplete or weak bond, negating the benefits of the process.

Investment in Equipment and Process Control

Vacuum brazing requires a significant investment in high-quality vacuum furnaces, precise temperature controllers, and robust testing facilities.

It is not a low-cost alternative to welding; it is a high-value process chosen when the performance and reliability of the final component justify the investment.

When to Choose Vacuum Brazing

Your decision should be based on the most critical requirement for your component.

- If your primary focus is ultimate strength and reliability: Choose vacuum brazing to create a monolithic joint that is often stronger than the parent material itself.

- If your primary focus is purity or hygiene: This flux-free, gap-free process is the definitive choice for medical, food, aerospace, or semiconductor applications.

- If your primary focus is joining dissimilar materials: Vacuum brazing provides a reliable and robust solution for creating metal-to-ceramic or other multi-material assemblies.

- If your primary focus is dimensional stability: The low-stress, controlled thermal cycle makes it ideal for precision components that cannot tolerate distortion.

By understanding its properties and requirements, you can leverage vacuum brazing to manufacture components that are simply not possible with other methods.

Summary Table:

| Property | Description |

|---|---|

| Strength | Joints are as strong or stronger than parent materials, with even stress distribution. |

| Cleanliness | Flux-free process eliminates contamination, ideal for medical and semiconductor uses. |

| Hermetic Sealing | Creates vacuum-tight, leak-proof seals for high-pressure and aerospace applications. |

| Dimensional Stability | Minimal distortion and warping due to controlled thermal cycles. |

| Material Versatility | Enables reliable joining of dissimilar materials like metals to ceramics. |

| High-Temperature Resistance | Withstands up to 800°C with corrosion-resistant filler metals. |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing performance and efficiency. Contact us today to discuss how we can support your projects with tailored vacuum brazing and other high-temperature processes!

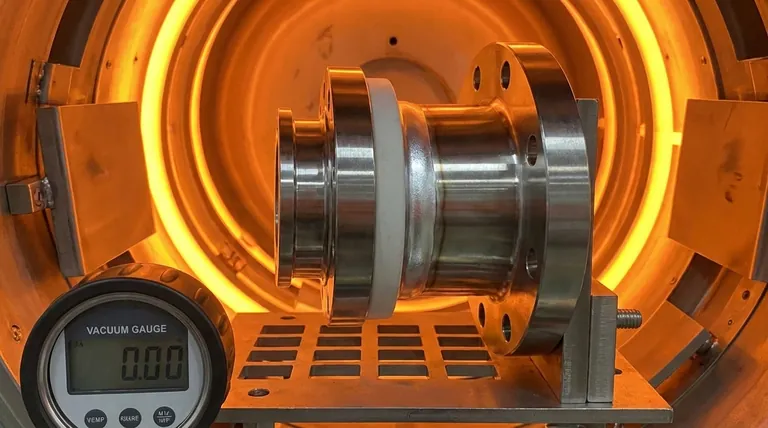

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing