Vacuum Spark Plasma Sintering (SPS) fundamentally outperforms traditional methods through direct volumetric heating. By utilizing pulsed electric current to heat the sample from the inside out, SPS achieves exceptionally high heating rates and full densification in minutes rather than hours. This rapid processing suppresses abnormal grain growth, resulting in TiB2-SiC composites with superior hardness and fracture toughness.

The decisive advantage of SPS lies in its ability to decouple densification from grain growth. By achieving full density through rapid heating before grains can coarsen, it produces a fine-grained microstructure that significantly enhances mechanical performance compared to traditional high-temperature furnaces.

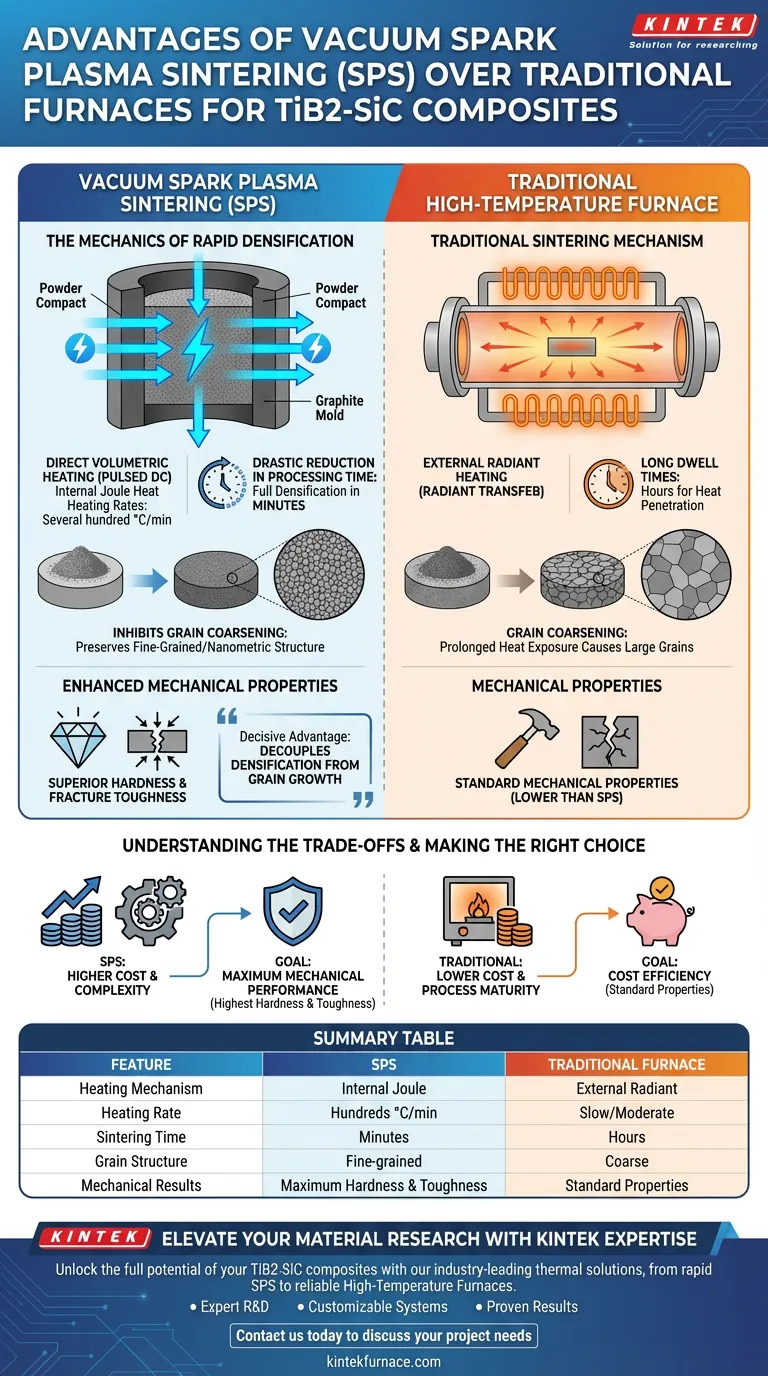

The Mechanics of Rapid Densification

Direct Volumetric Heating

Unlike traditional tube furnaces that rely on external heating elements and radiant heat transfer, SPS employs pulsed direct current (DC).

This current passes directly through the graphite mold and the TiB2-SiC powder compact itself.

This mechanism generates internal Joule heat, allowing the system to achieve heating rates of several hundred degrees per minute.

Drastic Reduction in Processing Time

Traditional sintering often requires long dwell times (holding times) to ensure heat penetrates the sample and closes pores.

SPS achieves full densification in an extremely short duration due to the combination of rapid internal heating and applied pressure.

This efficiency minimizes the material's total exposure to high temperatures.

Microstructural Control and Performance

Inhibiting Grain Coarsening

In traditional sintering, prolonged exposure to high heat typically causes grains to merge and grow (coarsening).

Large grains are detrimental to the mechanical integrity of ceramics like TiB2-SiC.

The rapid cooling and heating cycles of SPS effectively inhibit abnormal grain growth, preserving the material's fine-grained, often nanometric, structure.

Enhanced Mechanical Properties

The physical properties of TiB2-SiC composites are directly tied to their microstructure.

Because SPS maintains a fine grain size while achieving high density, the resulting material exhibits superior hardness.

Furthermore, the refined microstructure improves fracture toughness, making the composite more resistant to cracking under stress compared to conventionally sintered counterparts.

Understanding the Trade-offs

Equipment Cost and Complexity

While SPS offers superior material properties, it involves higher initial capital investment compared to traditional furnaces or vacuum hot presses.

The technology relies on complex pulsed power generators and precise vacuum controls.

Process Maturity

Traditional vacuum hot press furnaces utilize simpler, more mature process control logic.

For applications where extreme speed is not critical, traditional methods may offer a balance of lower energy consumption and reduced equipment costs, provided the specific parameter optimization (like alloying) is managed correctly.

Making the Right Choice for Your Goal

When deciding between SPS and traditional sintering for TiB2-SiC composites, consider your specific performance requirements:

- If your primary focus is Maximum Mechanical Performance: Choose SPS to achieve the highest possible hardness and fracture toughness through fine-grain retention.

- If your primary focus is Cost Efficiency: Evaluate traditional vacuum hot press methods, which offer lower equipment costs and simpler operation, though with longer processing times.

SPS is the definitive choice for high-performance ceramics where microstructural integrity cannot be compromised.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional High-Temp Furnace |

|---|---|---|

| Heating Mechanism | Internal Joule Heating (Pulsed DC) | External Radiant Heating |

| Heating Rate | Several hundred degrees per minute | Slow/Moderate |

| Sintering Time | Minutes | Hours |

| Grain Structure | Fine-grained (inhibits growth) | Coarse (due to long dwell times) |

| Mechanical Results | Maximum hardness & toughness | Standard mechanical properties |

Elevate Your Material Research with KINTEK Expertise

Unlock the full potential of your TiB2-SiC composites with KINTEK’s industry-leading thermal solutions. Whether you require the rapid densification of Spark Plasma Sintering (SPS) or the reliable performance of our Vacuum, Tube, or High-Temperature Lab Furnaces, we provide the precision tools necessary for superior microstructural control.

Why partner with KINTEK?

- Expert R&D: Our systems are engineered for advanced material science and ceramic synthesis.

- Customizable Systems: From Muffle and Rotary to CVD and Vacuum systems, we tailor equipment to your unique lab requirements.

- Proven Results: Achieve higher hardness, better fracture toughness, and optimized densification.

Ready to transform your sintering process? Contact us today to discuss your project needs and let our technical team design the perfect solution for your laboratory.

Visual Guide

References

- German Alberto Barragán De Los Rios, Patricia Fernández‐Morales. Numerical Simulation of Aluminum Foams by Space Holder Infiltration. DOI: 10.1007/s40962-024-01287-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the two types of vacuum furnaces based on heating form? Choose the Right Design for Your Lab

- What physical conditions does a high-temperature vacuum furnace provide for SiC skeletons? Expert Sintering Guide

- What are the challenges of relying solely on a vacuum in furnace applications? Overcome Key Operational Hurdles

- How does vacuum sintering improve surface finish? Achieve Superior, Oxide-Free Results

- How does vacuum tempering contribute to energy efficiency? Superior furnace design slashes thermal waste and cuts costs.

- How does vacuum sintering compare to traditional smelting methods? Discover Key Differences for Your Manufacturing Needs

- Why is a high vacuum system necessary when using SPS for Ti-6Al-4V composites? Ensure Material Integrity

- What are the primary functions of a laboratory drying oven in banana peel activated carbon? Optimize Every Process Step