In short, vacuum tempering achieves energy efficiency through superior furnace design. The process relies on furnaces built with advanced insulation and precise heating systems that dramatically reduce thermal waste, unlike conventional atmosphere furnaces. This construction minimizes the energy required to both reach and maintain target temperatures.

The primary driver of energy efficiency in vacuum tempering is not the vacuum itself, but the high-performance furnace technology it necessitates. By fundamentally minimizing heat loss through advanced insulation and eliminating inefficient heat transfer, these systems keep energy focused entirely on the workpiece.

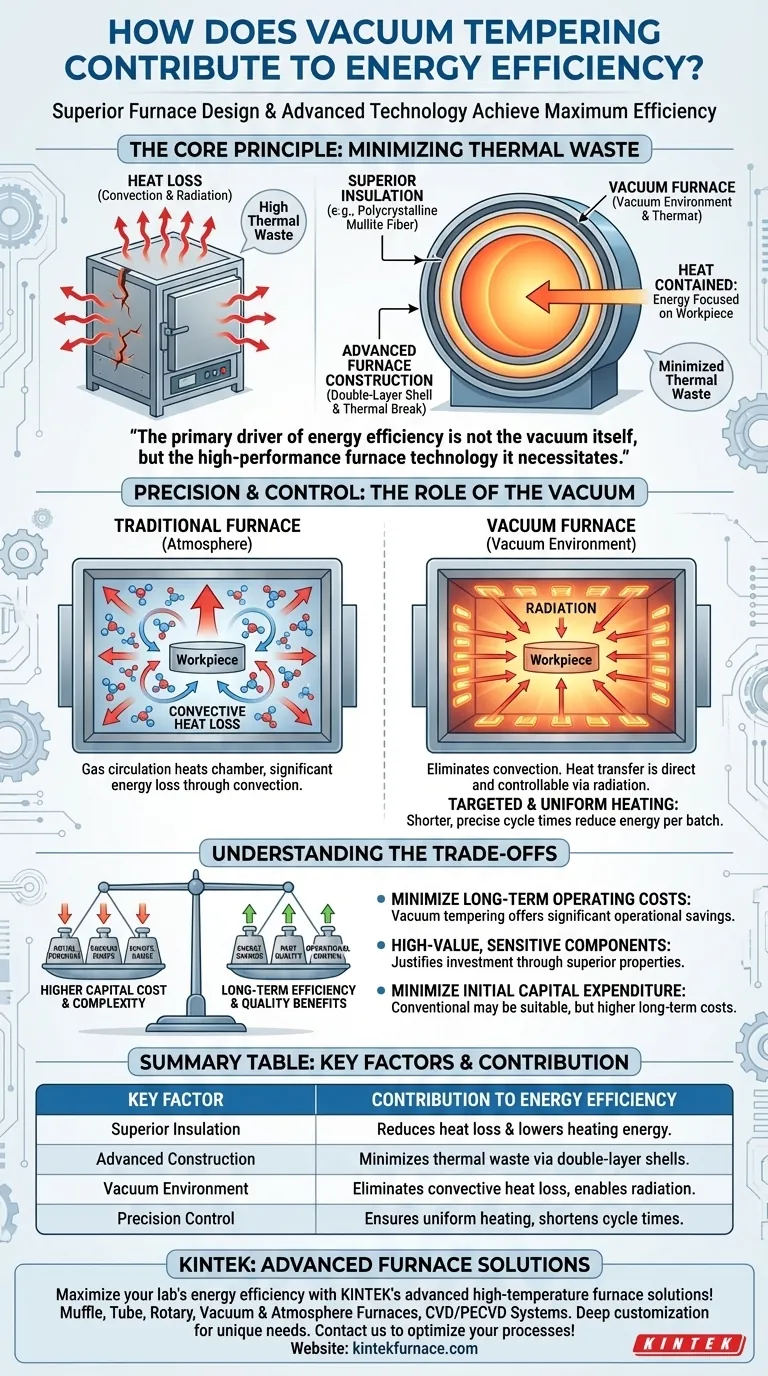

The Core Principle: Minimizing Thermal Waste

Energy efficiency in any heating process is a battle against thermal loss. Heat naturally wants to escape to a cooler environment. Vacuum furnaces are engineered from the ground up to prevent this escape, ensuring the energy you pay for is used to treat the metal, not to heat the factory.

Superior Insulation Materials

A significant portion of a furnace's energy consumption goes into heating the furnace chamber itself and then compensating for heat that leaks out.

Vacuum furnaces utilize high-quality insulation, such as polycrystalline mullite fiber. This material has low thermal mass and low thermal conductivity, which provides two distinct benefits. First, it requires less energy to heat up, and second, it is extremely effective at preventing heat from escaping the chamber.

Advanced Furnace Construction

Modern vacuum furnaces often feature double-layer furnace shells. This design creates a gap between the inner and outer walls of the furnace.

This gap, combined with air insulation or a water-cooling jacket, acts as a thermal break. It severely restricts the path for heat to conduct from the hot inner chamber to the cool outer surface, effectively trapping the thermal energy inside.

Precision and Control: The Role of the Vacuum

While the furnace construction saves energy by preventing heat loss, the vacuum environment itself contributes to efficiency through more precise and effective heating methods.

Eliminating Convective Heat Loss

In a traditional furnace, the chamber is filled with air or a protective gas. This gas heats up, circulates, and carries a tremendous amount of heat away from the parts and the heating elements—a process called convection.

By removing the air to create a vacuum, you eliminate this major path of heat loss. Heat transfer occurs primarily through radiation, which travels in a straight line from the heating elements to the parts. This is a far more direct and controllable method of heating.

Targeted and Uniform Heating

Because heat transfer is dominated by radiation, engineers can design and place heating elements for optimal, uniform coverage. This precision ensures that the entire workload reaches the target temperature at the same time.

This uniformity eliminates the need to "over-soak" the load—holding it at temperature longer than necessary just to ensure colder spots catch up. Shorter, more precise cycle times directly translate to lower energy consumption per batch.

Understanding the Trade-offs

While highly efficient, vacuum tempering is not a universal solution. A clear understanding of the trade-offs is essential for making an informed decision.

Higher Initial Capital Cost

Vacuum furnaces are complex machines that include vacuum pumps, sophisticated controls, and high-purity chamber materials. Their initial purchase price is significantly higher than that of a comparable atmosphere furnace.

Cycle Time Considerations

The need to pump the chamber down to a vacuum adds time to the beginning of every cycle. While the heating itself is efficient, the overall floor-to-floor time must be evaluated for your specific production needs.

Increased Maintenance Complexity

A vacuum furnace has more systems that require specialized maintenance, including the vacuum pumps, seals, and instrumentation. This can lead to higher maintenance costs and requires more skilled technicians compared to simpler furnace types.

Making the Right Choice for Your Goal

The decision to use vacuum tempering hinges on balancing its efficiency and quality benefits against its higher initial cost and complexity.

- If your primary focus is minimizing long-term operating costs: Vacuum tempering's high energy efficiency and reduced need for consumable process gases offer significant operational savings over the equipment's lifespan.

- If your primary focus is processing high-value, sensitive components: The clean, bright finish and superior metallurgical properties from vacuum tempering often justify the investment, with energy savings being a secondary benefit.

- If your primary focus is minimizing initial capital expenditure: A conventional atmosphere furnace may be a more suitable choice, but you must account for higher long-term energy and consumable costs in your budget.

Ultimately, choosing vacuum tempering is an investment in long-term efficiency, part quality, and precise operational control.

Summary Table:

| Key Factor | Contribution to Energy Efficiency |

|---|---|

| Superior Insulation | Reduces heat loss and lowers energy needed for heating |

| Advanced Furnace Construction | Minimizes thermal waste through double-layer shells |

| Vacuum Environment | Eliminates convective heat loss, enables radiation-based heating |

| Precision Control | Ensures uniform heating, shortens cycle times |

Maximize your lab's energy efficiency with KINTEK's advanced high-temperature furnace solutions! By leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vacuum tempering systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you reduce energy costs and enhance performance. Contact us today to discuss how we can optimize your processes and deliver reliable, efficient solutions!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance