The laboratory drying oven acts as a critical process control tool across three distinct stages of converting banana peels into activated carbon. Its primary functions are to dehydrate raw biomass for mechanical processing, facilitate the deep penetration of chemical activating agents, and stabilize the final pore structure of the washed product.

The oven is not merely a dehydrator; it is a structural stabilizer. By controlling moisture levels at specific temperatures, it enables the physical fracturing of biomass, the chemical fixation of activators like KOH, and the preservation of the final carbon network.

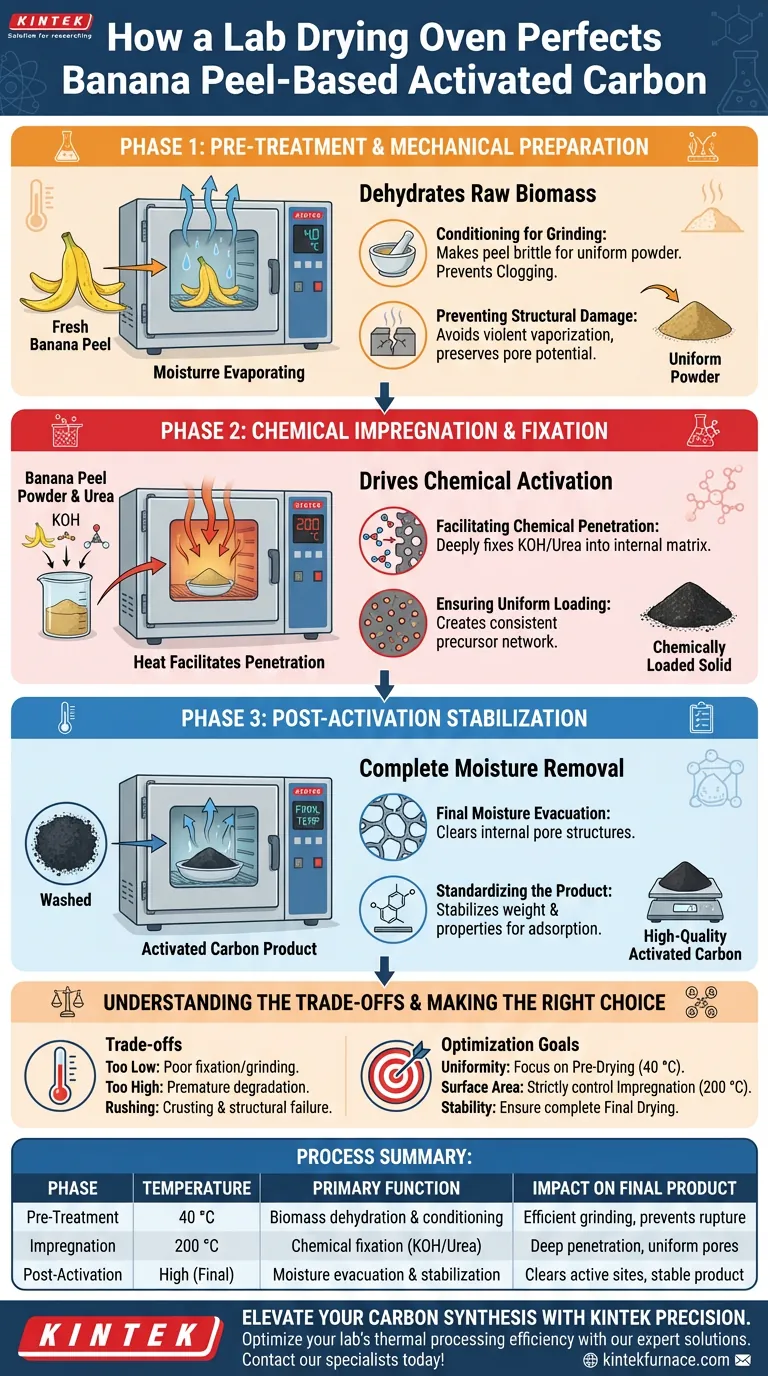

Phase 1: Pre-Treatment and Mechanical Preparation

Conditioning for Grinding

The first function of the oven is to prepare the raw banana peels for size reduction.

By drying the raw biomass at a low temperature of 40 °C, the oven removes surface moisture that makes the peels pliable or sticky.

This dehydration makes the material brittle, ensuring it can be efficiently ground into a uniform powder without clogging milling equipment.

Preventing Structural Damage

While the primary goal is grinding efficiency, this stage also serves a protective function.

Removing physically adsorbed water prevents violent vaporization during later high-temperature stages.

Without this initial drying, rapid steam expansion in a furnace could rupture the biomass, leading to a collapse of the potential pore structure.

Phase 2: Chemical Impregnation and Fixation

Facilitating Chemical Penetration

Once the banana peel powder is mixed with chemical agents—specifically potassium hydroxide (KOH) and urea—the oven drives the activation process.

This stage utilizes a significantly higher temperature of 200 °C.

This heat treatment drives the chemical solution deep into the precursor material, ensuring the agents are not just coating the surface but are fixed within the internal matrix.

Ensuring Uniform Loading

The controlled heat allows the activating agents to crystallize uniformly.

This uniformity is essential for creating a consistent network of micropores and mesopores during the final carbonization.

It transforms the mixture from a wet slurry into a chemically loaded solid ready for thermal decomposition.

Phase 3: Post-Activation Stabilization

Final Moisture Removal

After the carbonized material is washed to remove residual chemicals, the oven performs its final function.

It is used to completely dry the resulting activated carbon.

This step ensures that all moisture is evacuated from the newly formed internal pore structures.

Standardizing the Product

This final drying stage stabilizes the weight and properties of the carbon.

It ensures the material is chemically stable and ready for adsorption applications.

Leaving moisture in the pores at this stage would artificially inflate the weight and block the active sites needed for filtration.

Understanding the Trade-offs

Temperature Sensitivity

Selecting the correct temperature for each stage is a critical balancing act.

If the temperature is too low, moisture remains trapped, leading to poor grinding or incomplete chemical fixation.

If the temperature is too high (especially during pre-drying), you risk premature thermal degradation or burning of the organic components before activation even begins.

Process Time vs. Efficiency

Oven drying is often the most time-consuming step in the synthesis process.

Rushing this step by increasing heat can cause crusting, where the outside dries fast and traps moisture inside.

This trapped moisture can lead to structural failure when the material is eventually exposed to extreme heat in the carbonization furnace.

Making the Right Choice for Your Goal

To maximize the quality of your banana peel-based activated carbon, align your oven usage with your specific processing targets:

- If your primary focus is particle uniformity: Prioritize thorough pre-drying at 40 °C to maximize the brittleness and grindability of the raw peels.

- If your primary focus is surface area development: Strictly control the 200 °C impregnation stage to ensure KOH and urea are deeply fixed into the carbon precursor.

- If your primary focus is storage stability: Ensure the final drying phase is complete to prevent moisture re-adsorption and pore blockage.

Precision in drying dictates the integrity of the final carbon structure.

Summary Table:

| Process Phase | Temperature | Primary Function | Impact on Final Product |

|---|---|---|---|

| Pre-Treatment | 40 °C | Biomass dehydration & conditioning | Ensures efficient grinding and prevents structural rupture |

| Impregnation | 200 °C | Chemical fixation (KOH/Urea) | Facilitates deep penetration for uniform pore development |

| Post-Activation | High (Final) | Moisture evacuation & stabilization | Clears active sites and ensures chemical/weight stability |

Elevate Your Carbon Synthesis with KINTEK Precision

Precise thermal control is the difference between a collapsed structure and a high-surface-area adsorbent. KINTEK provides industry-leading lab solutions tailored for biomass processing and material science. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your unique research needs.

Ready to optimize your lab's thermal processing efficiency?

Contact our specialists today to find your perfect solution!

Visual Guide

References

- Joanna Sreńscek-Nazzal, Beata Michalkiewicz. Chemical Activation of Banana Peel Waste-Derived Biochar Using KOH and Urea for CO2 Capture. DOI: 10.3390/ma17040872

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the core role of a vacuum melting furnace in the process of recovering elemental magnesium from slag? | Achieve High-Purity Metal Recovery

- What is the significance of using a vacuum annealing furnace for zirconium sponge? Ensure Purity and Process Stability

- What are the key advantages of using a vacuum sintering furnace? Achieve High-Purity, Dense Materials with Superior Control

- Why is high-vacuum degasification necessary for HfO2 coatings? Prevent Ir Layer Delamination and Bubbling

- What role does a vacuum oven play in the activation process of Ce-MOF? Unlock Maximum Porosity and Surface Area

- How should a crucible be handled after being heated in a vacuum furnace? Ensure Material Integrity & Accurate Results

- What are the key characteristics of vacuum hardening? Achieve Clean, Precise Metal Hardening for Superior Components

- What advantages does plasma nitriding equipment offer over traditional gas nitriding? Mastering Microstructure Control