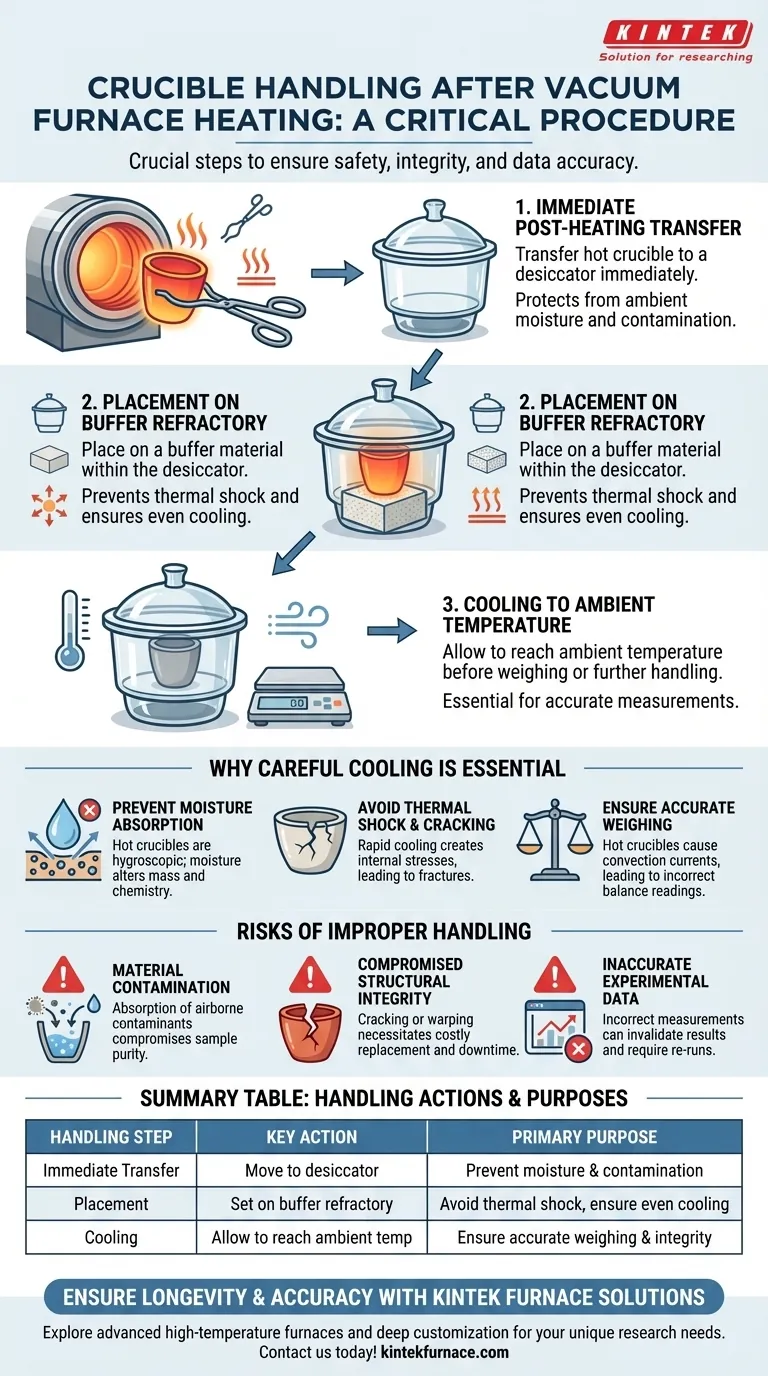

After being heated in a vacuum furnace, a crucible must be carefully transferred to a desiccator to cool, placed on a suitable buffer refractory material, and allowed to reach ambient temperature before any further handling or weighing. This procedure prevents moisture absorption, thermal shock, and ensures the integrity of the crucible and the accuracy of subsequent measurements.

Safely handling a crucible post-vacuum furnace heating is critical to maintaining its structural integrity and ensuring the accuracy of any measurements. The primary goal is to protect the hot crucible from atmospheric moisture and rapid temperature changes during the cooling phase.

Immediate Post-Heating Handling

Transfer to a Desiccator

Immediately upon removal from the vacuum furnace, the hot crucible should be transferred to a desiccator. This specialized container maintains a dry atmosphere, protecting the crucible from absorbing ambient moisture.

Use of a Buffer Refractory Material

Within the desiccator, the crucible must be placed on a buffer refractory material. This material acts as an intermediary layer, preventing direct contact with the desiccator's base and distributing heat more evenly.

Why Careful Cooling is Essential

Preventing Moisture Absorption

Crucibles, especially those made from ceramic materials, can be highly hygroscopic when hot. Direct exposure to humid air can lead to rapid moisture absorption, altering its mass and potentially compromising experimental results.

Avoiding Thermal Shock and Cracking

Rapid or uneven cooling can induce thermal shock in the crucible material. Thermal shock creates internal stresses that can lead to cracking, especially in brittle ceramic or quartz crucibles.

Ensuring Accurate Weighing

For applications requiring precise mass measurements (e.g., gravimetric analysis), the crucible must be at ambient temperature before weighing. A hot crucible creates convection currents around the balance, leading to inaccurate readings.

Understanding the Trade-offs and Risks

Improper handling of a crucible after vacuum furnace heating carries significant risks that can impact both experimental results and equipment longevity.

Risk of Material Contamination

Exposing a hot crucible directly to the atmosphere can lead to the absorption of airborne contaminants or moisture. This can alter the crucible's mass or chemical composition, compromising the purity of subsequent samples.

Compromised Structural Integrity

Neglecting the use of a buffer refractory or rapid cooling can cause the crucible to crack or warp. A damaged crucible cannot be reliably used for future experiments, leading to replacement costs and downtime.

Inaccurate Experimental Data

Weighing a crucible that has not fully cooled or has absorbed moisture will introduce errors into mass measurements. Such inaccuracies can invalidate experimental data, leading to incorrect conclusions or the need for costly re-runs.

Making the Right Choice for Your Goal

Proper crucible handling after vacuum furnace heating prioritizes both safety and data integrity.

- If your primary focus is crucible longevity and preventing damage: Ensure immediate transfer to a desiccator with a buffer refractory material to facilitate slow, even cooling.

- If your primary focus is precise mass measurement: Always allow the crucible to cool completely to ambient temperature within a desiccator before weighing.

- If your primary focus is preventing sample contamination: Utilize the desiccator for cooling to protect the hot crucible from any atmospheric moisture or particulate matter.

By adhering to these careful handling procedures, you ensure the reliability of your materials and the accuracy of your scientific work.

Summary Table:

| Handling Step | Key Action | Primary Purpose |

|---|---|---|

| Immediate Transfer | Move crucible to a desiccator | Prevent moisture absorption and contamination |

| Placement | Set on a buffer refractory material | Avoid thermal shock and ensure even cooling |

| Cooling | Allow to reach ambient temperature in desiccator | Ensure accurate weighing and maintain structural integrity |

Ensure the longevity of your crucibles and the accuracy of your results with KINTEK's precision furnace solutions.

Proper post-heating handling is just one part of a successful thermal process. KINTEK's advanced high-temperature furnaces, including our Vacuum & Atmosphere Furnaces, are engineered for superior performance and reliability. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions. Our strong deep customization capability allows us to tailor equipment like Tube Furnaces and CVD/PECVD Systems to your unique experimental requirements, ensuring optimal outcomes and protecting your valuable materials.

Contact us today to discuss how our expertise can enhance your laboratory's capabilities and efficiency.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification