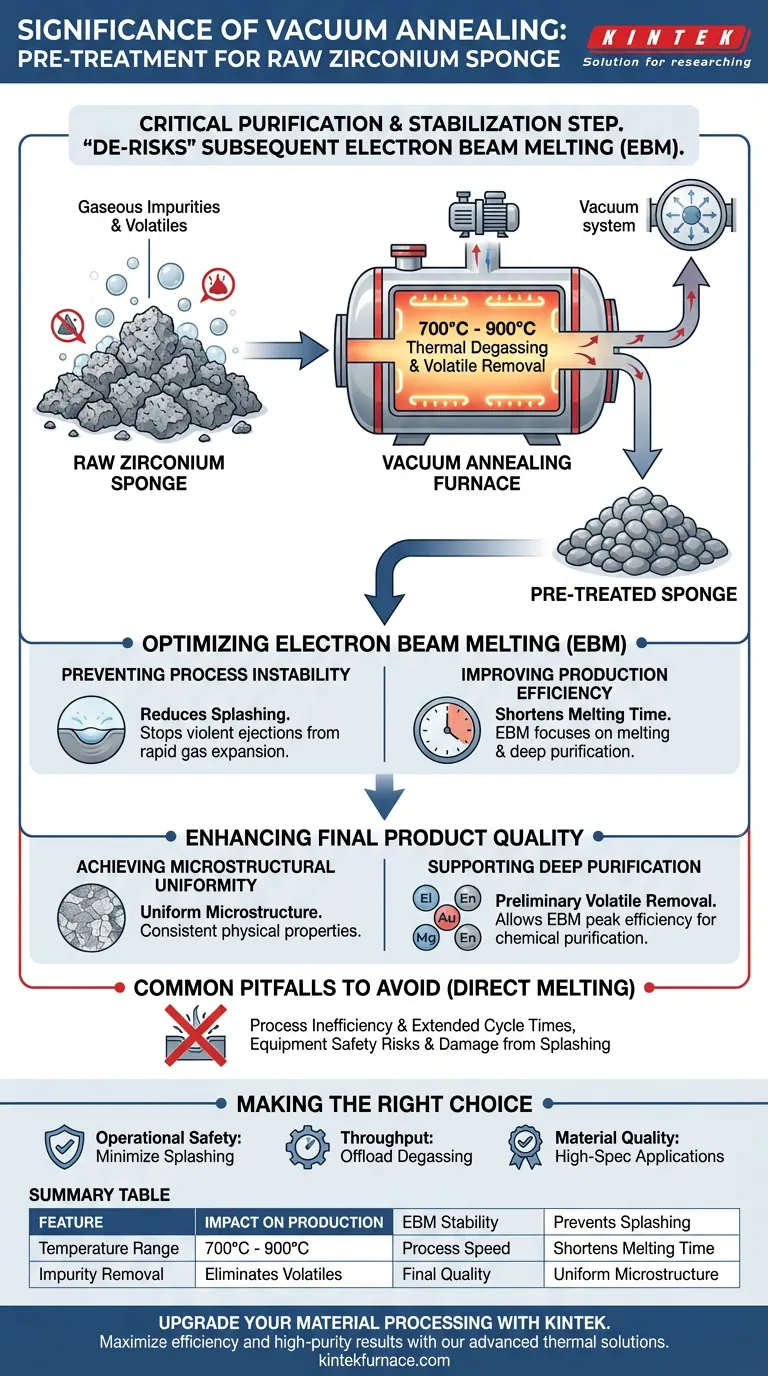

Vacuum annealing acts as a critical purification and stabilization step for raw zirconium sponge. By subjecting the material to temperatures between 700 and 900 degrees Celsius in a vacuum environment, this process removes significant gaseous impurities and volatiles before the metal undergoes final melting.

The primary value of this pre-treatment is that it "de-risks" the subsequent electron beam melting process. By handling bulk degassing early, it prevents dangerous splashing, accelerates melting times, and ensures the final zirconium ingot has a uniform internal structure.

The Mechanism of Pre-Treatment

Targeting Volatile Components

Raw zirconium sponge is rarely pure; it naturally contains high levels of gaseous impurities and volatile components.

Using a vacuum annealing furnace addresses this by creating a controlled environment for thermal degassing.

The Temperature Sweet Spot

The process specifically targets a temperature range of 700 to 900 degrees Celsius.

At these temperatures, the volatile components within the sponge are released and evacuated by the vacuum system, effectively "cleaning" the sponge of bulk contaminants prior to the liquid phase.

Optimizing Electron Beam Melting (EBM)

Preventing Process Instability

The most immediate operational benefit is the reduction of splashing during the subsequent electron beam melting phase.

If raw sponge is melted directly, the rapid expansion of trapped gases can cause violent ejections of molten material.

Pre-treatment removes these gases beforehand, creating a calm, stable melt pool when the high-energy electron beams eventually strike the material.

Improving Production Efficiency

Annealing significantly shortens the melting time required in the electron beam furnace.

Because the sponge is already pre-conditioned and partially degassed, the EBM equipment can focus its energy on melting and deep purification rather than bulk gas removal.

Enhancing Final Product Quality

Achieving Microstructural Uniformity

The benefits of vacuum annealing extend beyond the manufacturing process and into the material properties of the final product.

Ingots produced from pre-treated sponge exhibit a more uniform microstructure, ensuring consistent physical properties throughout the metal.

Supporting Deep Purification

While the electron beam furnace is excellent at removing metallic impurities (like aluminum, titanium, and iron) and interstitial elements (like oxygen and nitrogen), pre-treatment lightens the load.

By performing a "preliminary removal" of volatiles, the annealing step allows the EBM process to operate at peak efficiency for deep chemical purification.

Common Pitfalls to Avoid

The Risk of Direct Melting

Skipping the vacuum annealing step might seem like a way to save time, but it often leads to process inefficiency.

Without pre-treatment, the EBM furnace must handle the entire burden of degassing. This frequently results in extended cycle times that negate any time saved by skipping the annealing stage.

Compromising Equipment Safety

High levels of volatiles in raw sponge can threaten the stability of the electron beam itself.

The splashing caused by non-annealed sponge does not just lower material yield; it can contaminate the vacuum chamber and damage sensitive furnace components.

Making the Right Choice for Your Process

Depending on your specific production constraints, the role of vacuum annealing changes slightly.

- If your primary focus is Operational Safety: Prioritize annealing to minimize splashing and protect the vacuum systems of your electron beam furnace.

- If your primary focus is Throughput: Use annealing to offload the degassing work, thereby reducing the cycle time required for the more energy-intensive electron beam melting.

- If your primary focus is Material Quality: Rely on annealing to establish the uniform microstructure required for high-specification zirconium applications.

Pre-treating zirconium sponge is not merely a cleaning step; it is a fundamental prerequisite for a stable, efficient, and high-quality melting campaign.

Summary Table:

| Feature | Impact on Zirconium Production |

|---|---|

| Temperature Range | 700℃ - 900℃ for optimal thermal degassing |

| Impurity Removal | Eliminates volatile components and gaseous impurities |

| EBM Stability | Prevents violent splashing during electron beam melting |

| Process Speed | Shortens final melting times by offloading degassing |

| Final Quality | Ensures uniform microstructure and high-spec purification |

Upgrade Your Material Processing with KINTEK

Maximize your laboratory's efficiency and ensure high-purity results with KINTEK’s advanced thermal solutions. Backed by expert R&D and precision manufacturing, we provide high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems designed to meet the most rigorous pre-treatment standards.

Whether you are refining zirconium sponge or developing specialized alloys, our customizable furnaces deliver the uniform heating and vacuum stability your research demands.

Ready to optimize your high-temperature workflows? Contact our technical experts today to find the perfect system for your unique needs.

Visual Guide

References

- М.М. Pylypenko, A.О. Drobyshevska. MAGNESIUM-THERMAL METHOD OF SPONGE ZIRCONIUM OBTAINING. DOI: 10.46813/2024-149-052

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the primary function of a laboratory vacuum drying oven? Essential Electrode Sheet Processing Explained

- How does a vacuum environment affect heat transfer? Optimize Lithium Battery Drying with Conduction Mastery

- What role do vacuum furnaces play in the automotive industry? Enhance Durability and Performance in Vehicle Parts

- Why is a vacuum drying oven necessary for Pt-perovskite nanofibers? Optimize Catalyst Dispersion and Performance

- Why is a vacuum high-temperature box furnace critical for Ti-11Cr alloys? Ensure High Purity Homogenization

- How do continuous vacuum furnaces contribute to metal annealing and hardening? Achieve Superior Metallurgical Purity

- Why is a vacuum heater used to preheat the deposition chamber? Enhance Coating Adhesion & Purity

- What critical tasks does a vacuum drying oven perform for WPU films? Ensure Defect-Free Composite Material Integrity