In essence, continuous vacuum furnaces contribute to metal annealing and hardening by creating an exceptionally pure and precisely controlled environment. By removing air and other atmospheric gases, these furnaces prevent undesirable chemical reactions like oxidation, ensuring the heat treatment process modifies the metal's internal structure without degrading its surface. This results in components with superior mechanical properties, strength, and a clean finish.

The primary value of a vacuum furnace is not the heat, but the absence of atmosphere. By eliminating oxygen and other reactive gases, you can heat and cool a metal to alter its internal properties without the collateral damage of surface contamination, unlocking its full performance potential.

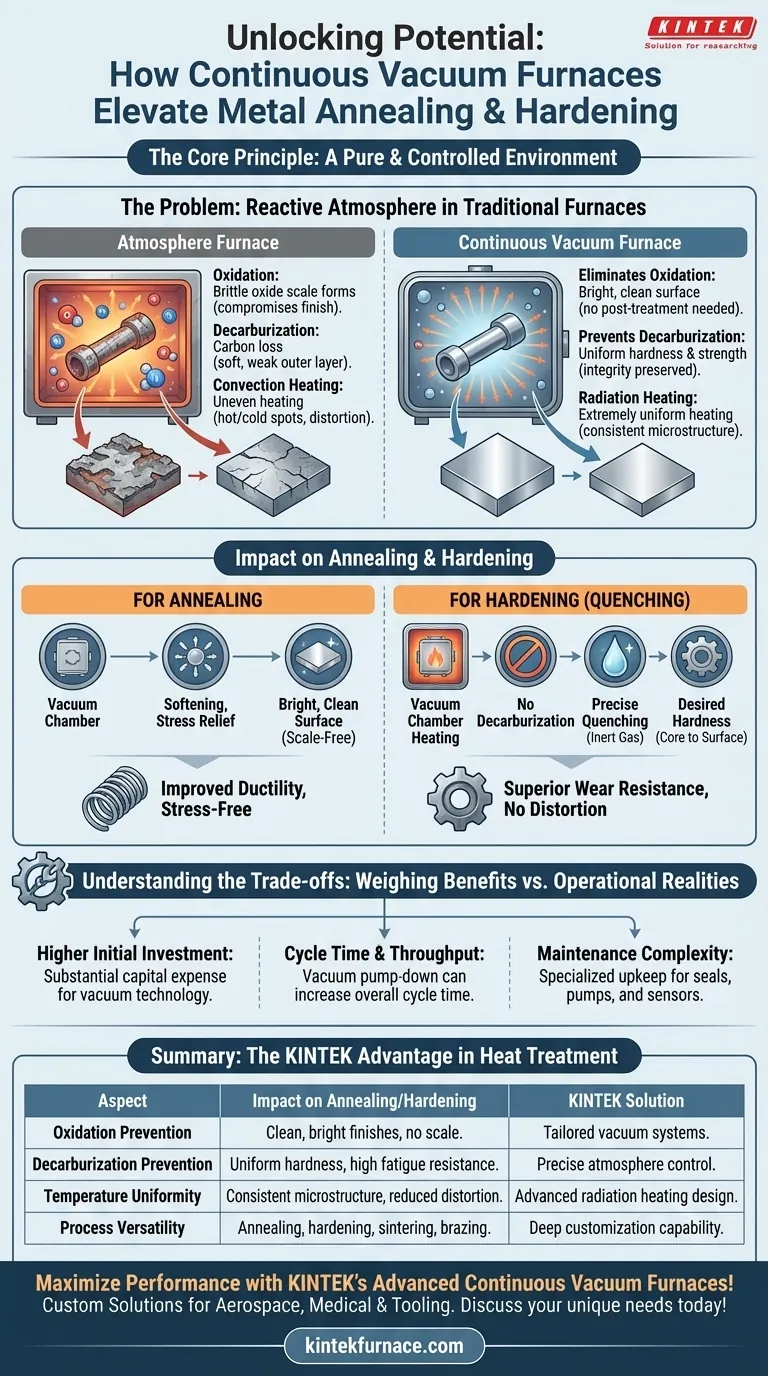

The Core Principle: A Controlled Atmosphere

To understand the impact of vacuum furnaces, you must first appreciate the problems they solve. Traditional furnaces heat parts in the presence of air, which is a cocktail of reactive gases.

Eliminating Oxidation and Decarburization

At high temperatures, the oxygen in the air aggressively reacts with a metal's surface, forming a brittle layer of oxide scale. This process, oxidation, compromises surface finish and can require costly secondary cleaning operations.

Another reaction, decarburization, occurs when carbon atoms migrate from the surface of steel alloys. This creates a soft, weak outer layer that severely reduces the fatigue life and wear resistance of the hardened part.

A vacuum environment starves these reactions of the gases they need to occur, preserving the integrity of the metal's surface and its chemical composition.

Ensuring Temperature Uniformity

In a traditional furnace, heat is transferred largely by convection (moving air). This can lead to uneven heating, गर्म and cold spots, and part distortion.

In a vacuum, heat is transferred primarily through radiation. This allows for extremely uniform heating across the entire workpiece, ensuring that目标d microstructures are achieved 목표istently throughout the part. This precision is critical for meeting tight tolerances.

How This Impacts Annealing and Hardening

The controlled environment 경찰ctly translates to higher-quality outcomes in specific heat treatment processes.

For Annealing

The goal of annealing is to soften a metal, relieve internal stresses, and improve its ductility. By performing this in a vacuum, the part emerges estrés-free and with a bright, clean surface, free from the scale that would form in an atmosphere furnace.

For Hardening (Quenching)

Hardening requires heating a metal to a critical temperature and then cooling it rapidly (quenching). A vacuum环境 prevents surface decarburization during the heating phase, ensuring the surface becomes just as hard as the core.

The furnace then allows for precise control over the quenching process, often using high-pressure inert gas, to achieve the desired hardness without the risk of cracking or distortion.

Understanding the Trade-offs

While vacuum furnaces offer superior results, they are not the universal solution for every application. It's crucial to weigh their benefits against their operational realities.

Higher Initial Investment

Vacuum furnaces represent a significantly larger capital expense compared to standard atmospheric furnaces. The cost of the vacuum chamber, pumping systems, and sophisticated controls is substantial.

Cycle Time and Throughput

Pumping a chamber down to a deep vacuum takes time. While "continuous" models streamline this by moving parts through a series of connected chambers, the overall cycle time can still be longer than atmospheric processes, potentially impacting high-volume production.

Maintenance Complexity

High-vacuum systems are complex machines. They require diligent, specialized maintenance to ensure the integrity of seals, the health of a bomba, and the accuracy of sensors. A leak can compromise an entire batch of parts.

Making the Right Choice for Your Process

Your choice of furnace technology should be driven by the end requirements of your component.

- If your primary focus is maximum material integrity and performance: For mission-critical parts in aerospace, medical, or high-performance tooling, a vacuum furnace is often the only way to meet stringent specifications.

- If your primary focus is high-volume, cost-sensitive production: For less demanding applications where surface oxidation is acceptable or can be cleaned post-process, a traditional atmospheric furnace may be more economical.

- If your primary focus is process versatility: A vacuum furnace is a multi-tool, capable of performing hardening, annealing, tempering, sintering, and even brazing in a single, contaminant-free environment.

Ultimately, investing in a vacuum furnace is a decision to prioritize the metallurgical purity and final performance of your product above all else.

Summary Table:

| Aspect | Impact on Annealing/Hardening |

|---|---|

| Oxidation Prevention | Eliminates surface scale, ensuring clean, bright finishes without post-treatment. |

| Decarburization Prevention | Maintains carbon content for uniform hardness and improved fatigue resistance. |

| Temperature Uniformity | Achieves consistent microstructures via radiation heating, reducing part distortion. |

| Process Versatility | Supports annealing, hardening, and more in one contaminant-free environment. |

Unlock the full potential of your metal heat treatments with KINTEK's advanced continuous vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior metallurgical purity and performance for industries like aerospace, medical, and tooling. Don't let oxidation or decarburization compromise your results—contact us today to discuss how our furnaces can elevate your processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control