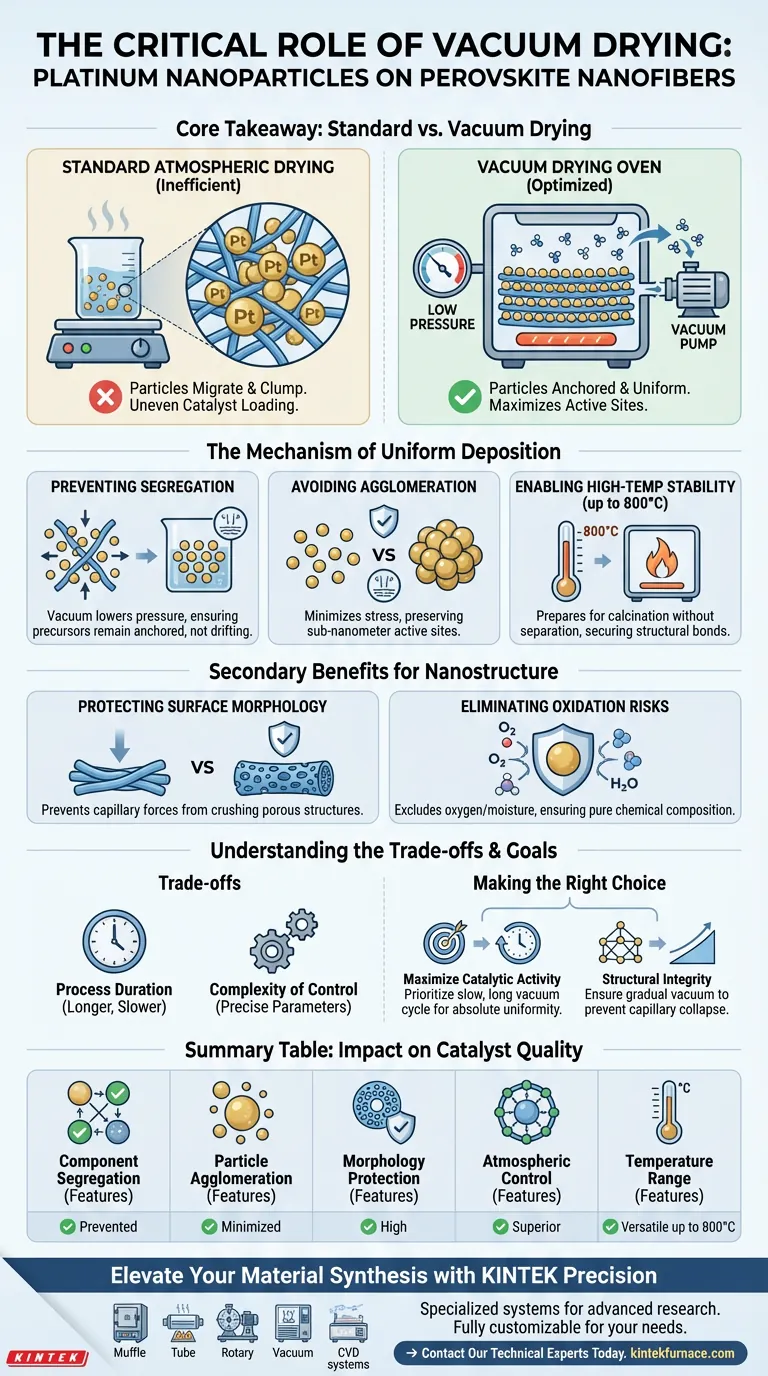

The critical role of a vacuum drying oven in this process is to ensure the uniform distribution of platinum precursors while preventing structural defects. By removing solvents under controlled vacuum conditions, often over long durations, you prevent the platinum species from migrating, segregating, or clumping together (agglomeration) on the perovskite nanofiber surface.

Core Takeaway Standard drying methods often cause suspended particles to migrate and clump as solvents evaporate, leading to uneven catalyst loading. Vacuum drying eliminates this by removing solvents under reduced pressure—sometimes even at elevated temperatures—locking the platinum precursors in place to maximize the available active sites.

The Mechanism of Uniform Deposition

Preventing Component Segregation

The primary challenge in depositing nanoparticles is maintaining their dispersion during the drying phase. As solvents evaporate, surface tension and capillary forces naturally pull particles together.

A vacuum drying oven counters this by lowering the environmental pressure, which alters the evaporation dynamics. This controlled environment ensures that platinum precursors remain anchored to the perovskite surface rather than drifting together.

Avoiding Agglomeration

Agglomeration is the enemy of catalytic efficiency. If platinum particles clump together, their effective surface area decreases significantly, wasting expensive material.

By utilizing a vacuum environment, the process minimizes the thermal and physical stresses that typically drive particles to cluster. This preserves the sub-nanometer active sites required for high-performance catalysis.

Enabling High-Temperature Stability

Uniquely, this process may require sustaining vacuum conditions across a wide temperature range, sometimes reaching as high as 800°C.

Operating under vacuum at these temperatures prepares the material for the final calcination stage. It ensures that the transition from a wet precursor to a solid catalyst happens without component separation, securing the structural bond between the platinum and the perovskite nanofibers.

Secondary Benefits for Nanostructure (Contextual)

protecting Surface Morphology

While the primary goal is platinum distribution, the vacuum environment also protects the delicate perovskite nanofibers.

Rapid evaporation at atmospheric pressure can generate strong capillary forces that crush porous structures. Vacuum drying mitigates this, preserving the loose, porous morphology and high specific surface area essential for gas diffusion and reactivity.

Eliminating Oxidation Risks

Although perovskites are generally stable, the interface between the metal nanoparticle (Platinum) and the support can be sensitive during formation.

Vacuum drying effectively excludes oxygen and moisture. This prevents premature oxidation of the metallic precursors or the nanofiber support, ensuring that the final chemical composition is purely the result of the intended synthesis, not environmental contamination.

Understanding the Trade-offs

Process Duration

Vacuum drying is rarely a fast process. The primary reference notes that long-duration drying is often required to achieve the necessary uniformity. This creates a bottleneck in manufacturing compared to rapid, atmospheric drying techniques.

Complexity of Parameter Control

Unlike a standard oven, a vacuum system requires precise balancing of pressure and temperature. If the pressure drops too quickly, solvents may boil violently ("bumping"), which can physically dislodge the coating rather than settling it.

Making the Right Choice for Your Goal

To maximize the efficacy of your platinum-perovskite catalyst, tailor your drying approach to your specific outcome:

- If your primary focus is Maximizing Catalytic Activity: Prioritize a slow, long-duration vacuum cycle to ensure absolute uniformity of the platinum dispersion, preventing even minor agglomeration.

- If your primary focus is Structural Integrity: Ensure the vacuum is applied gradually to lower the boiling point of the solvent gently, preventing capillary forces from collapsing the nanofiber pores.

By controlling the solvent removal process via vacuum, you transform a simple drying step into a critical stabilization phase that defines the final performance of your catalyst.

Summary Table:

| Feature | Impact on Catalyst Quality |

|---|---|

| Component Segregation | Prevented; maintains uniform distribution of platinum precursors |

| Particle Agglomeration | Minimized; preserves high surface area and active catalytic sites |

| Morphology Protection | High; prevents capillary forces from collapsing porous nanofibers |

| Atmospheric Control | Superior; eliminates oxidation risks during the drying phase |

| Temperature Range | Versatile; supports stable processing up to 800°C under vacuum |

Elevate Your Material Synthesis with KINTEK Precision

Don't let improper drying compromise your high-performance catalysts. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for advanced material research. Whether you are stabilizing platinum nanoparticles or calcining perovskite structures, our lab high-temperature furnaces are fully customizable to meet your unique processing needs.

Ready to achieve superior uniformity and structural integrity?

→ Contact Our Technical Experts Today

Visual Guide

References

- Min Xu, John T. S. Irvine. Synergistic growth of nickel and platinum nanoparticles via exsolution and surface reaction. DOI: 10.1038/s41467-024-48455-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is a laboratory vacuum furnace and what environment does it create? Achieve Purity in High-Temp Processing

- What vacuum level is required for CP-Ti annealing? Achieve 2.8 x 10^-6 Torr for Peak Purity

- Why do the crucible residues remaining after the vacuum distillation of magnesium alloys possess high recycling value?

- What are the applications of high-temperature vacuum sintering furnaces? Essential for Aerospace, Electronics, and Medical Materials

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What is a vacuum sintering furnace? Achieve High-Purity, Dense Materials

- What are the technical challenges of SEM in-situ furnaces? Optimize High-Temperature Dynamic Observation

- What are the advantages of vacuum heat treatment? Achieve Superior Cleanliness and Performance for Critical Parts