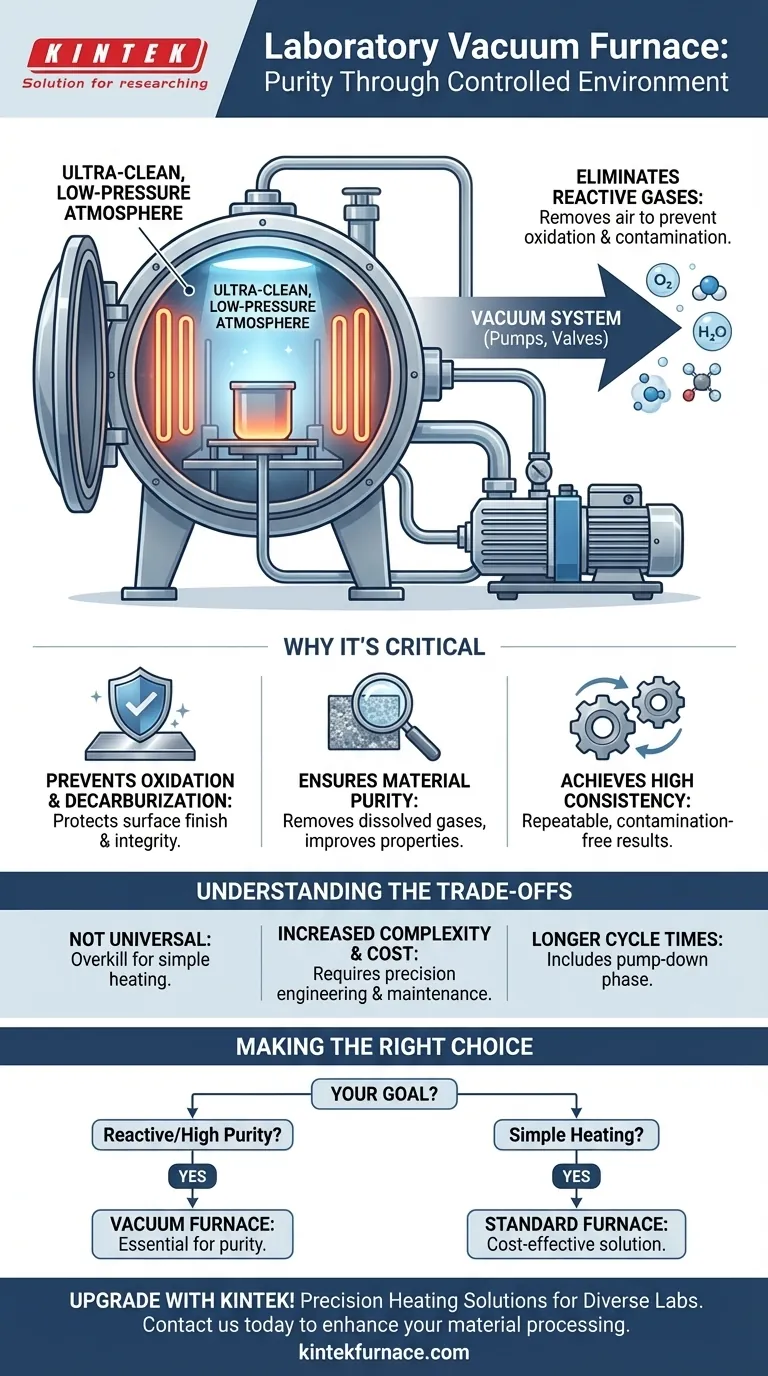

In short, a laboratory vacuum furnace is a specialized heating device that creates a low-pressure, near-vacuum environment for thermal processing. It achieves this by using a system of vacuum pumps to remove air and other gases from a sealed chamber, resulting in an ultra-clean atmosphere that prevents unwanted chemical reactions like oxidation and contamination.

The crucial insight is that a vacuum furnace is less about generating heat and more about controlling the purity of the environment in which heating occurs. By removing nearly all atmospheric gases, it enables high-temperature processing of sensitive materials without altering their chemical composition.

How a Vacuum Furnace Creates Its Environment

A vacuum furnace is fundamentally a sealed chamber connected to a sophisticated vacuum system. The process is straightforward but requires precise engineering.

The Role of the Vacuum System

A vacuum system, composed of vacuum pumps, valves, and measurement gauges, is the heart of the furnace. Its sole purpose is to evacuate the air from the sealed furnace chamber before the heating process begins.

This reduces the internal pressure to a level far below standard atmospheric pressure.

The Goal: Eliminating Reactive Gases

The primary goal of creating a vacuum is to remove oxygen, water vapor, and other reactive gases. These atmospheric components will readily react with many materials at high temperatures, causing undesirable effects.

By pumping these gases out, the furnace is left with an inert, or non-reactive, environment.

The Result: An Ultra-Clean Atmosphere

The resulting environment is an ultra-clean, low-pressure space. This prevents contamination from airborne impurities and ensures that the only reactions occurring are the ones intended by the heat treatment process itself.

Why This Environment Is Critical

The unique atmosphere inside a vacuum furnace is not just a feature; it is the reason for its existence. It enables processes that would be impossible in a standard furnace.

Preventing Oxidation and Decarburization

When metals are heated in the presence of oxygen, they oxidize—a process similar to rusting. A vacuum environment almost completely eliminates oxygen, protecting the material's surface finish and integrity.

Similarly, it prevents decarburization, which is the loss of carbon content from the surface of steel, a common issue in atmospheric heating.

Ensuring Material Purity and Properties

For advanced materials, aerospace components, and medical implants, purity is paramount. The vacuum prevents airborne impurities from embedding into the material during heating.

Furthermore, the vacuum can actually pull dissolved gases, like hydrogen and nitrogen, out of the material itself. This degassing process significantly improves the mechanical properties, strength, and fatigue life of the metal.

Achieving High Consistency

By precisely controlling the atmosphere, a vacuum furnace delivers highly consistent and repeatable results. Every batch is processed in an identical, contamination-free environment, which is essential for both scientific research and high-volume industrial production.

Understanding the Trade-offs

While powerful, a vacuum furnace is a specialized tool. Understanding its limitations is key to using it effectively.

Not a Universal Solution

A vacuum furnace is overkill for simple heating tasks where atmospheric reactions are not a concern. For some processes, a standard laboratory tube furnace that uses a specific purge gas (like argon or nitrogen) can provide a controlled atmosphere more simply and economically.

Increased Complexity and Cost

The vacuum pumps, high-integrity seals, and precise controls required for a vacuum furnace make it significantly more complex and expensive than a conventional atmospheric furnace. Maintenance of the vacuum system is also a critical consideration.

Longer Process Cycle Times

Achieving a deep vacuum takes time, known as the "pump-down" phase, which adds to the total process cycle. Controlled cooling within the vacuum can also be slower than simply exposing a part to ambient air.

Making the Right Choice for Your Process

Your specific goal determines whether a vacuum furnace is the right tool.

- If your primary focus is processing highly reactive materials or achieving maximum purity: A vacuum furnace is essential to prevent oxidation and remove contaminants.

- If your primary focus is simple heating without atmospheric sensitivity: A standard atmospheric or tube furnace is a more straightforward and cost-effective solution.

- If your primary focus is removing dissolved gases from molten metals: A specialized vacuum induction melting (VIM) furnace is the specific tool designed for this purpose.

Ultimately, choosing the correct thermal equipment begins with a clear understanding of how the processing atmosphere will impact your material.

Summary Table:

| Feature | Description |

|---|---|

| Environment | Low-pressure, near-vacuum atmosphere |

| Key Benefit | Prevents oxidation, decarburization, and contamination |

| Ideal For | Processing reactive materials, ensuring high purity |

| Limitations | Higher cost, complexity, and longer cycle times |

Upgrade your lab with precision heating solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our vacuum furnaces can enhance your material processing purity and efficiency!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What technological features enhance the efficiency of vacuum furnaces? Boost Performance with Advanced Control & Energy Savings

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability