In essence, a high-temperature vacuum sintering furnace is a specialized oven that allows for the heating of materials to extreme temperatures in an oxygen-free environment. Its core applications are in the creation of highly dense, pure, and high-performance materials that would be impossible to produce in a normal atmosphere, including advanced ceramics, specialty alloys, and powder metallurgy components for critical industries.

The true value of a vacuum sintering furnace is not just its ability to get hot, but its power to precisely control a material's final structure. By eliminating atmospheric contamination, it enables the synthesis of advanced materials with superior density, strength, and purity—the building blocks of modern aerospace, electronics, and medical technology.

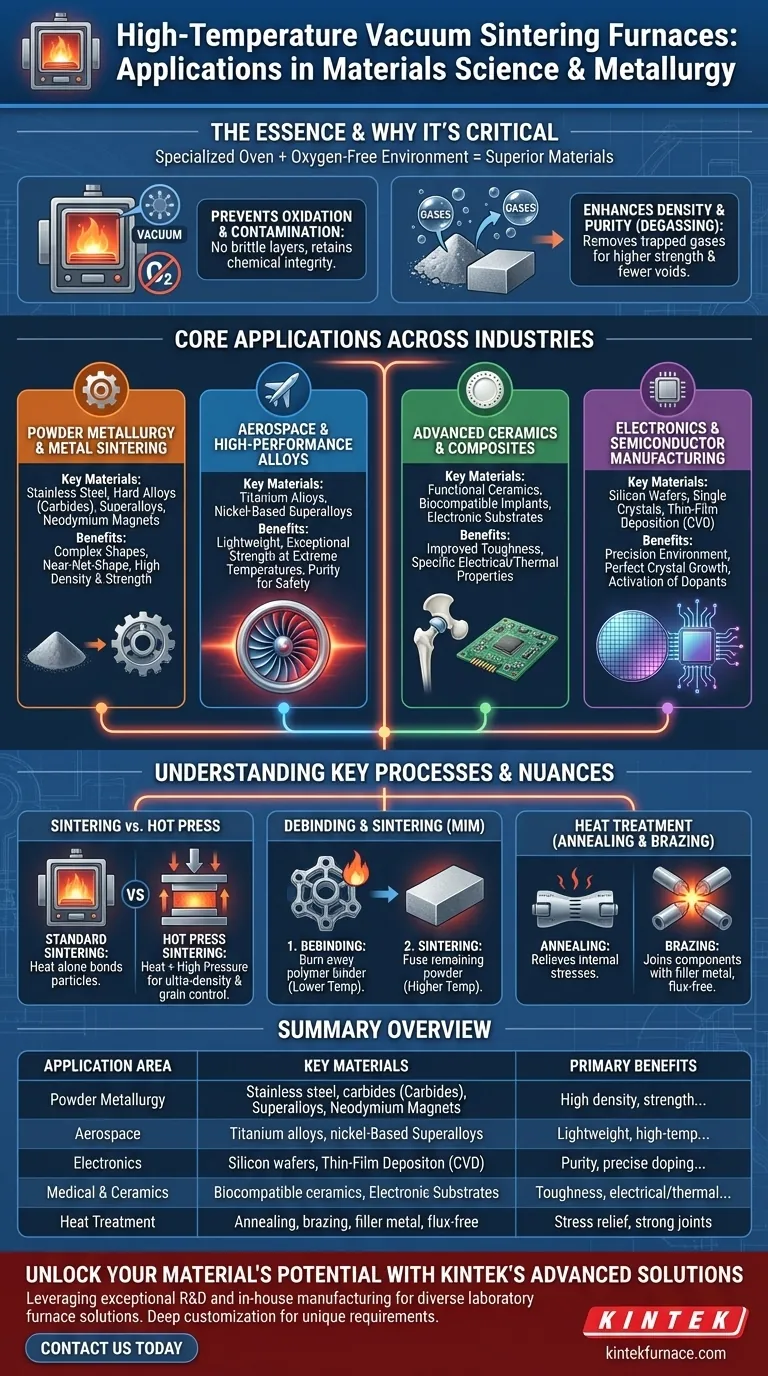

Why a Controlled Atmosphere is Critical

At the heart of this technology is the understanding that at high temperatures, most materials react aggressively with the air around them, especially oxygen. A vacuum furnace removes this variable entirely.

Preventing Oxidation and Contamination

When metals and other reactive materials are heated, they readily oxidize, forming a brittle, weak layer that compromises the material's integrity.

A vacuum environment removes the oxygen and other atmospheric gases, preventing these unwanted chemical reactions. This ensures the final product retains its intended chemical composition and superior mechanical properties.

Enhancing Material Density and Purity

The primary process, sintering, involves heating a compacted powder until its particles bond together, forming a solid mass.

In a vacuum, trapped gases within the powder can be easily removed. This process, known as degassing, allows the particles to fuse more completely, resulting in a final product with higher density, fewer internal voids, and greater strength.

Core Applications Across Industries

The ability to create pure, dense materials opens the door to a wide range of high-value applications where material failure is not an option.

Powder Metallurgy and Metal Sintering

This is the most common application, where fine metal powders are transformed into complex, near-net-shape solid parts.

Key materials include stainless steel, hard alloys (carbides), superalloys, and high-specific-gravity alloys used in everything from industrial cutting tools to engine components. It is also essential for producing high-performance magnets like Neodymium (NdFeB).

Aerospace and High-Performance Alloys

The aerospace industry relies on materials that are both lightweight and exceptionally strong at extreme temperatures.

Vacuum furnaces are critical for processing titanium alloys and nickel-based superalloys used in jet engine turbines, structural components, and other demanding applications where material purity is directly linked to safety and performance.

Advanced Ceramics and Composites

Unlike metals, ceramics are brittle. Vacuum sintering produces highly compacted functional ceramic parts with improved toughness and specific electrical or thermal properties.

This includes producing electronic component substrates, biocompatible medical implants, and components for armor or high-wear industrial machinery.

Electronics and Semiconductor Manufacturing

The precision of a vacuum environment is indispensable for the electronics industry.

Furnaces are used for growing large, perfect single crystals for semiconductors and optics, annealing silicon wafers to activate dopants and repair crystal lattice damage, and for thin-film deposition processes like Chemical Vapor Deposition (CVD).

Understanding Key Processes and Their Nuances

While "sintering" is the headline process, these furnaces are versatile tools used for several distinct thermal treatments.

Sintering vs. Hot Press Sintering

Standard sintering relies on heat alone to bond particles. For materials that are extremely difficult to densify, hot press sintering is used.

This process applies high mechanical pressure simultaneously with heat and vacuum, physically forcing the particles together to achieve near-theoretical density. It is often used to produce ultra-strong ceramics and restrain crystal grain growth in nanomaterials.

Debinding and Sintering

In Metal Injection Molding (MIM), metal powder is mixed with a polymer binder to form a complex shape. The part first undergoes a lower-temperature debinding process in the furnace to burn away the binder before being heated to a higher sintering temperature.

Heat Treatment: Annealing and Brazing

Beyond creating new parts, these furnaces modify existing ones. Vacuum annealing is used to relieve internal stresses in a machined part, making it less brittle.

Vacuum brazing uses a filler metal to join two components together. The vacuum ensures a perfectly clean, strong joint without the need for corrosive fluxes, which is critical for aerospace and medical assemblies.

Making the Right Choice for Your Goal

The specific process and material determine how a high-temperature vacuum furnace is used. Your end goal dictates the application.

- If your primary focus is manufacturing high-strength metal components: You will use powder metallurgy to sinter superalloys for aerospace or hard alloys for industrial tooling.

- If your primary focus is producing advanced electronic devices: Your application will be crystal growth, silicon wafer annealing, or thin-film deposition for the semiconductor industry.

- If your primary focus is creating ultra-dense ceramic parts: You will use sintering or hot-press sintering to create functional ceramics for electronic substrates or medical implants.

- If your primary focus is joining complex, high-purity assemblies: You will use vacuum brazing to create flux-free joints for critical components in aerospace or scientific instruments.

Ultimately, the high-temperature vacuum furnace is an enabling technology, foundational to the creation of the world's most advanced materials.

Summary Table:

| Application Area | Key Materials | Primary Benefits |

|---|---|---|

| Powder Metallurgy | Stainless steel, carbides, superalloys | High density, strength, complex shapes |

| Aerospace | Titanium alloys, nickel superalloys | Lightweight, high-temperature resistance |

| Electronics | Silicon wafers, single crystals | Purity, precise doping, thin-film deposition |

| Medical & Ceramics | Biocompatible ceramics, composites | Toughness, electrical/thermal properties |

| Heat Treatment | Annealing, brazing assemblies | Stress relief, strong flux-free joints |

Unlock the Potential of Your Materials with KINTEK's Advanced Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing aerospace alloys, electronics, or medical implants, we deliver tailored furnaces that ensure superior density, purity, and performance. Contact us today to discuss how we can enhance your material science and metallurgy projects—Get in touch now!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density