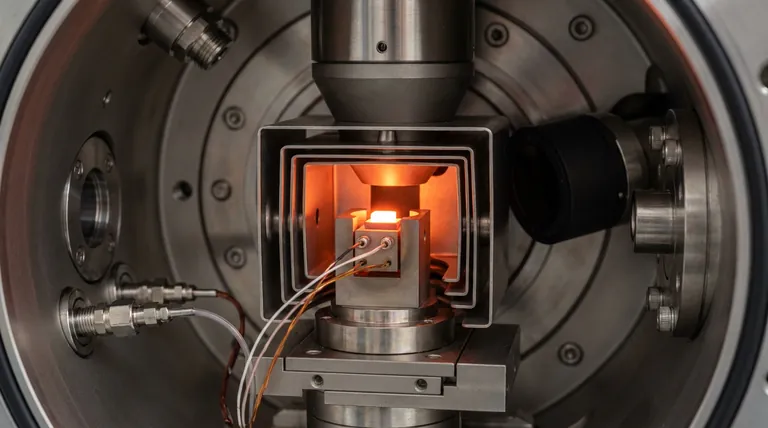

The primary technical hurdle addressed by specialized miniature vacuum furnaces is the safe integration of extreme environments within a delicate observation instrument. These devices are engineered to reach operating temperatures exceeding 1300°C and maintain compatibility with diverse gas atmospheres—including oxidizing, reducing, and neutral environments—while strictly protecting the Scanning Electron Microscope's (SEM) sensitive detectors and vacuum chamber.

Core Insight: The engineering success of these furnaces lies in decoupling the sample environment from the microscope's hardware. Through robust all-metal construction, they create a stable, localized thermal field that allows for high-temperature dynamic observation without thermally damaging the surrounding SEM architecture.

Managing Extreme Thermal Environments

High-Temperature Stability

The foremost challenge is achieving and maintaining temperatures exceeding 1300°C within a confined space.

Standard SEM stages cannot support these extremes without degradation. Miniature vacuum furnaces use specialized engineering to generate this heat locally at the sample.

Preserving the Thermal Field

For effective in-situ observation, the temperature must not only be high but also consistent.

These furnaces are designed to provide a stable thermal field. This stability is critical for capturing clear, real-time dynamic changes in the material structure without fluctuations that could distort the data.

Protecting Sensitive Components

The SEM column contains highly sensitive detectors and vacuum components that are intolerant to excess heat.

The furnace design isolates the high-temperature zone from the rest of the chamber. This prevents thermal radiation from damaging the internal vacuum chamber components or the detectors used for imaging.

Handling Complex Atmospheres

Atmospheric Versatility

Materials behave differently depending on the gas surrounding them, yet standard SEMs typically operate in a high vacuum.

These specialized furnaces address the need for compatibility with various atmospheres. They allow researchers to observe material behavior in reducing, neutral, and—most notably—oxidizing environments.

Robust Construction

Operating in reactive atmospheres (like oxidizing gases) at high temperatures accelerates corrosion and material failure.

To combat this, the furnaces utilize an all-metal construction. This robust build is specifically engineered to withstand the dual stress of extreme heat and reactive chemical environments.

Understanding the Trade-offs

Material Limitations

While the all-metal construction provides robustness, metals have physical limits regarding melting points and oxidation resistance.

Operating near the upper limit of 1300°C in aggressive atmospheres requires precise adherence to the equipment's engineering specifications to avoid degradation.

Integration Complexity

Achieving this level of isolation and control requires a complex, "miniature" design.

Users must manage the balance between the need for a stable thermal field and the physical constraints of fitting the furnace inside the tight quarters of an SEM vacuum chamber.

Making the Right Choice for Your Goal

When selecting or utilizing an in-situ SEM furnace, align the technical capabilities with your specific research needs.

- If your primary focus is oxidation studies: Prioritize a system with validated all-metal construction capable of resisting corrosion at your target temperatures.

- If your primary focus is phase transformation: Ensure the system guarantees a stable thermal field to prevent temperature drift during long-duration observations.

- If your primary focus is extreme heat: Verify the system is rated for temperatures exceeding 1300°C while explicitly checking its heat shielding capabilities for detector safety.

By leveraging these specialized furnaces, you transform the SEM from a static imaging tool into a dynamic, high-temperature laboratory.

Summary Table:

| Feature | Technical Challenge Addressed | Research Benefit |

|---|---|---|

| Temperature Range | Reaching >1300°C in confined spaces | Enables study of high-melting-point materials |

| Thermal Isolation | Protecting sensitive SEM detectors | Prevents hardware damage during heat cycles |

| All-Metal Build | Corrosion in oxidizing/reducing gases | Ensures durability in reactive atmospheres |

| Field Stability | Minimizing thermal drift | Guarantees clear, real-time dynamic imaging |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your in-situ SEM observations with advanced heating solutions tailored for excellence. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of your lab. Whether you need to stabilize thermal fields or protect sensitive instrumentation at 1300°C+, our engineering expertise ensures your research remains precise and protected.

Ready to upgrade your high-temperature capabilities? Contact us today to discuss your unique project requirements with our technical team!

References

- Jérôme Mendonça, Renaud Podor. Development of a microfurnace dedicated to <i>in situ</i> scanning electron microscope observation up to 1300 °C. III. <i>In situ</i> high temperature experiments. DOI: 10.1063/5.0207477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the key design features of a vacuum graphitizing furnace? Achieving High-Purity Graphitization

- Why is an industrial high vacuum sintering furnace required for high-porosity Hastelloy-X? Ensure Alloy Integrity

- What advantages does vacuum brazing offer over other methods? Achieve Superior Joint Quality and Efficiency

- Why is the precise control of H2 and C2H2 flow rates essential in plasma carburizing of AISI 316L? Master the S-Phase

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What are the limitations of high vacuum furnaces? Understand Costs, Time, and Material Challenges

- What role does a high vacuum evaporation system play in Sb2Se3 thin film preparation? Ensure High Purity & Performance

- Why is precise temperature and time control in a vacuum brazing furnace necessary for joint performance? Get Expert Tips