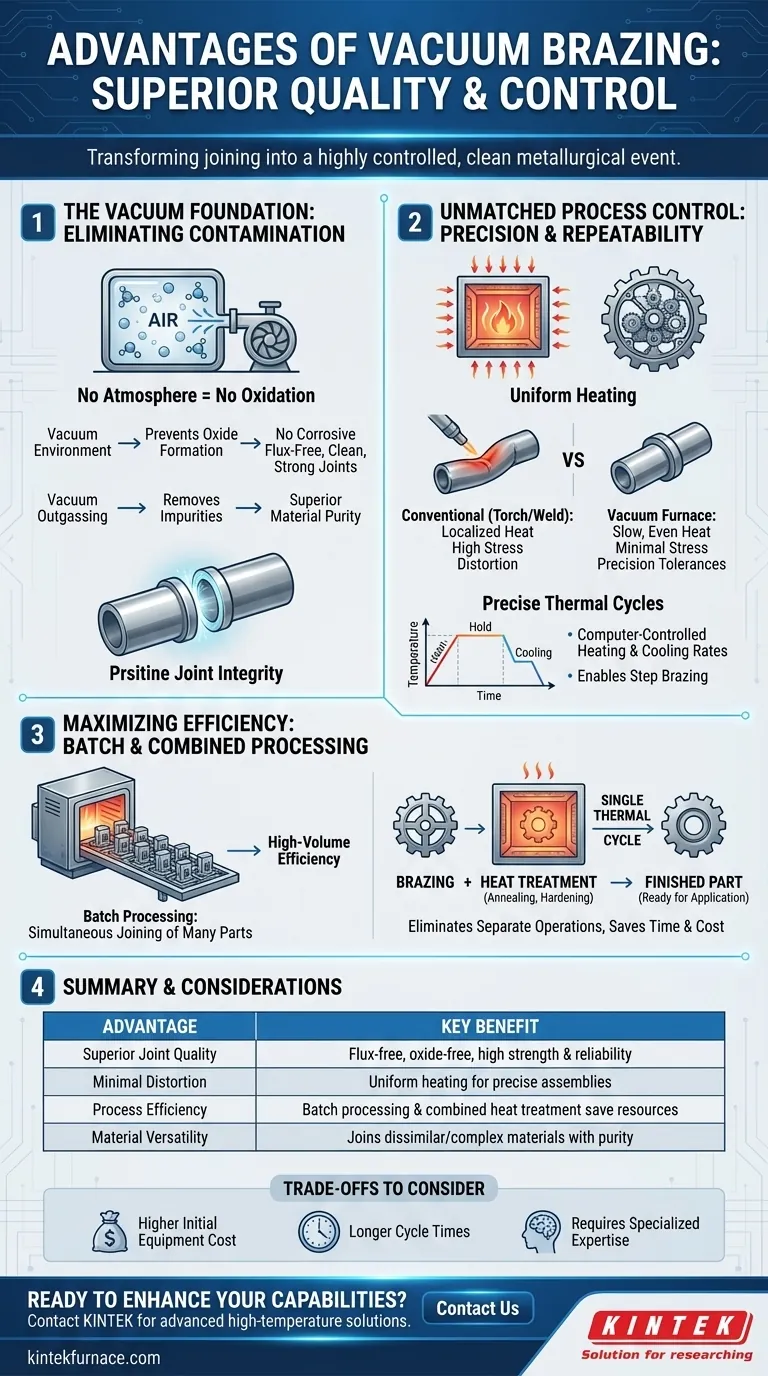

In essence, vacuum brazing offers superior joint quality and process control by transforming the joining process from a simple application of heat into a highly controlled, clean, metallurgical event. Its primary advantages are the creation of strong, flux-free joints with minimal distortion, the ability to join dissimilar or complex materials, and the efficiency of combining heat treatment and joining into a single, repeatable cycle.

Vacuum brazing is not just another way to join metal; it is a comprehensive thermal processing solution. Its core advantage lies in using a vacuum to create a pristine environment, enabling a level of control over temperature and chemistry that is impossible to achieve with conventional methods.

The Foundation: Why a Vacuum Environment is Transformative

The "vacuum" in vacuum brazing is the key enabler. By removing the atmosphere from the furnace chamber, the process fundamentally changes the way materials interact at high temperatures.

Eliminating Oxidation and Contamination

In a normal atmosphere, heating metals creates oxides on the surface, which act as a barrier and weaken the final joint. Traditional brazing fights this with chemical fluxes.

A high vacuum removes virtually all oxygen, preventing oxides from ever forming. This eliminates the need for corrosive flux, which in turn means no post-braze cleaning is required and the risk of flux entrapment causing future corrosion is gone. The result is an exceptionally clean, strong, and reliable joint.

Achieving Superior Material Purity

The vacuum environment also actively pulls other contaminants, such as trapped gases and volatile elements, out of the base materials themselves. This outgassing effect purifies the components during the heating cycle.

This leads to a finished assembly with higher metallurgical integrity and improved mechanical properties, a critical benefit for high-performance applications in aerospace, medical, and scientific industries.

Unlocking Unmatched Process Control

Beyond cleanliness, a vacuum furnace provides an unparalleled level of control over the entire thermal cycle, ensuring precision and repeatability.

Uniform Heating for Minimal Distortion

Unlike welding or torch brazing which apply intense, localized heat, a vacuum furnace heats the entire assembly slowly and uniformly. All surfaces—internal and external—reach the brazing temperature at nearly the same time.

This dramatically reduces the thermal stress and distortion common with other methods. It makes vacuum brazing the ideal process for delicate, thin-walled components or complex assemblies where maintaining tight dimensional tolerances is critical.

Precise Thermal Cycles

Modern vacuum furnaces allow for precise, computer-controlled programming of heating rates, holding times, and cooling rates. This control is essential for managing the material properties of sensitive alloys.

It also enables step brazing, where multiple joints on a single part are brazed in sequence using filler metals with different melting points, all within a single furnace run.

Maximizing Manufacturing Efficiency and Capability

The controlled environment and batch-processing nature of vacuum brazing create significant advantages for production.

Brazing Multiple Joints and Assemblies Simultaneously

A key economic benefit is the ability to process many joints or even entire assemblies in a single batch. Once the furnace cycle is optimized, you can load hundreds or thousands of parts and braze them all at once.

This batch processing capability makes it highly efficient for medium to high-volume production runs, offsetting the longer individual cycle time.

Combining Brazing and Heat Treatment

This is one of the most powerful advantages. Because the process is already taking place in a precisely controlled furnace, other heat treatment operations like annealing, hardening, or age hardening can be integrated into the same thermal cycle.

Combining these steps eliminates entire manufacturing operations, saving significant time, cost, and material handling. A part can go into the furnace for brazing and come out fully heat-treated and ready for its final application.

Understanding the Trade-offs

While powerful, vacuum brazing is not a universal solution. Its benefits must be weighed against its specific operational requirements.

Higher Initial Equipment Cost

Vacuum furnaces and their associated systems represent a significant capital investment compared to the equipment needed for welding or torch brazing. This is a major barrier to entry for smaller shops.

Longer Cycle Times

A typical vacuum furnace cycle can last for several hours, from initial pump-down to final cooling. This makes the process less suitable for one-off repairs or very low-volume production where speed for a single part is the priority.

Requirement for Specialized Expertise

Properly designing vacuum-brazed joints, selecting filler metals, and programming furnace cycles requires significant metallurgical knowledge and operator training. It is a more technically demanding process than many conventional joining methods.

Making the Right Choice for Your Application

Selecting the correct joining process requires aligning the method's strengths with your project's most critical goals.

- If your primary focus is ultimate joint quality and cleanliness: Vacuum brazing is unparalleled for creating flux-free, oxide-free joints in mission-critical parts for aerospace, medical, or scientific instruments.

- If your primary focus is joining complex assemblies with minimal distortion: The uniform, controlled heating of vacuum brazing is the ideal choice for delicate components or assemblies with tight dimensional tolerances.

- If your primary focus is manufacturing efficiency at scale: Vacuum brazing allows for batch processing and can combine joining with heat treatment, drastically reducing total manufacturing steps for production runs.

- If your primary focus is low cost, rapid prototyping, or simple field repairs: Conventional methods like welding or torch brazing are often more practical and cost-effective for less demanding applications.

By understanding these distinct advantages and trade-offs, you can confidently determine if vacuum brazing is the optimal technology to achieve your engineering goal.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Joint Quality | Flux-free, oxide-free joints with high strength and reliability |

| Minimal Distortion | Uniform heating reduces thermal stress for precise assemblies |

| Process Efficiency | Batch processing and combined heat treatment save time and cost |

| Material Versatility | Ability to join dissimilar or complex materials with high purity |

Ready to enhance your laboratory's capabilities with advanced high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum brazing and furnace technologies can deliver superior joint quality, efficiency, and tailored performance for your specific needs!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions