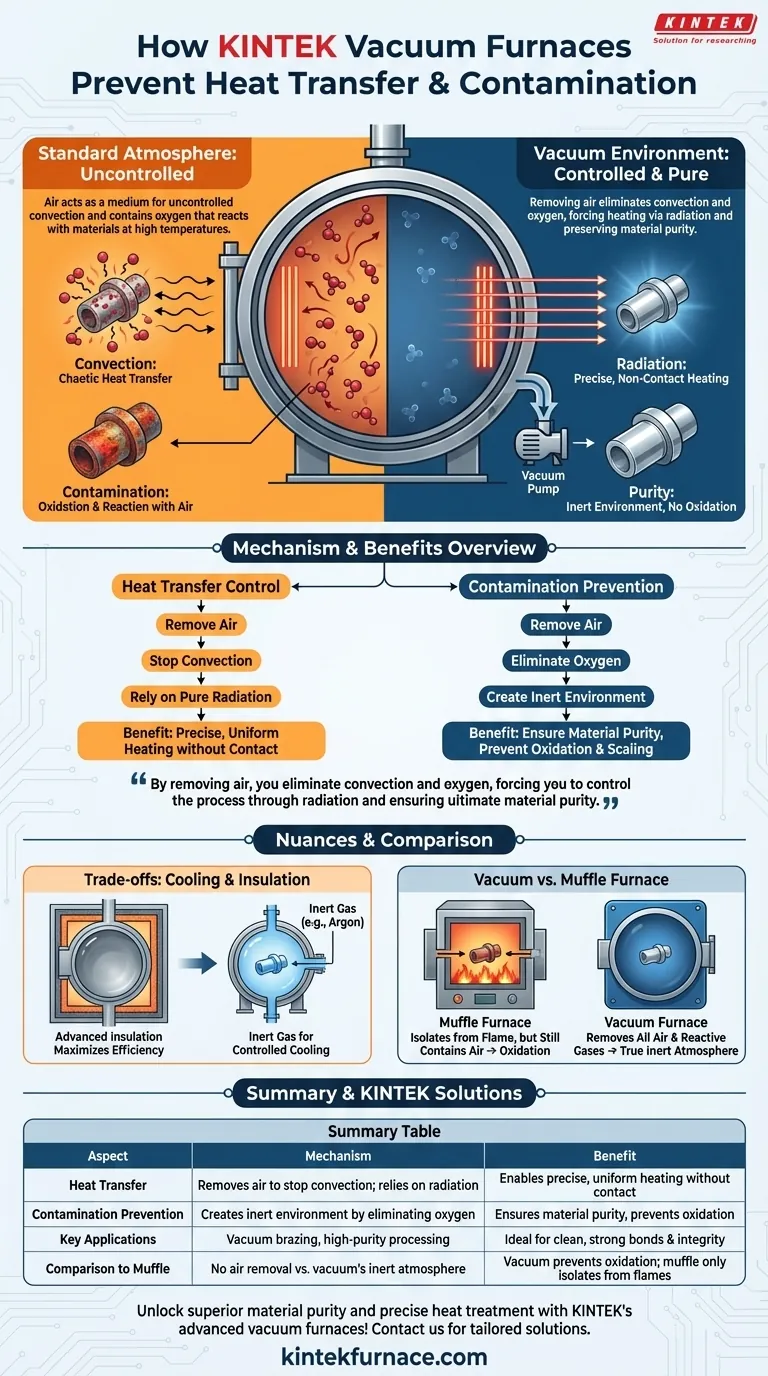

At its core, a vacuum furnace prevents unwanted heat transfer and contamination by removing the primary medium that causes them: air. By creating a near-perfect vacuum, it eliminates gas molecules that would otherwise transfer heat through convection and react with the material to cause oxidation.

A vacuum doesn't just create an empty space; it fundamentally changes the physics of the environment. By removing air, you eliminate convection as a heat transfer mechanism and remove the oxygen that causes contamination, forcing you to control the process through radiation and ensuring ultimate material purity.

How a Vacuum Furnace Controls Heat Transfer

In a standard atmosphere, heat moves in three ways: conduction, convection, and radiation. A vacuum furnace is designed to eliminate one of these to gain precise control.

The Problem: Uncontrolled Convection

Air and other gases are fluids that transfer heat through a process called convection. Hot gas molecules move around, colliding with the workpiece and transferring their energy in a way that can be difficult to control uniformly.

The Solution: Removing the Medium

By pumping nearly all the air out of the chamber, a vacuum furnace effectively stops convective heat transfer. There are simply not enough gas molecules left to move heat from the furnace walls or elements to the workpiece in a meaningful way.

Relying on Pure Radiation

With convection gone, heat transfer occurs almost exclusively through thermal radiation. The furnace's heating elements emit infrared energy, which travels through the vacuum and is absorbed directly by the workpiece.

This allows for highly controlled and non-contact heating, though it requires careful design of the heating elements to ensure the energy is distributed evenly across the part's surface.

How a Vacuum Furnace Prevents Contamination

Many high-temperature processes fail not because of the heat itself, but because of how the material reacts with the air around it.

The Root Cause: Oxidation and Reaction

At high temperatures, most metals will readily react with the oxygen in the air. This reaction, known as oxidation, creates a layer of scale or discoloration on the surface, which compromises the material's integrity, appearance, and performance.

Creating an Inert Environment

A vacuum furnace solves this problem by removing the source of the reaction. By pumping out the air, it creates a chemically inert environment free from oxygen and other reactive gases.

Preserving Material Purity

This ensures that the material remains clean and bright throughout the heating and cooling cycle. This is critical for processes like vacuum brazing, where perfectly clean surfaces are necessary to form a strong, reliable bond.

Understanding the Trade-offs and Nuances

While powerful, the vacuum environment introduces its own set of engineering challenges that must be managed.

The Challenge of Cooling

Just as a vacuum prevents heat from getting to the part via convection, it also prevents it from leaving. This means cooling can be very slow. To control the cooling rate and achieve specific material properties, some processes intentionally introduce a small amount of inert gas (like argon or nitrogen) back into the chamber to speed up cooling.

The Importance of Insulation

Since heat is radiating from the elements, the furnace chamber itself must be exceptionally well-insulated. Modern vacuum furnaces use advanced, multi-layer insulation to minimize heat loss to the outside environment, maximizing energy efficiency.

Contrast with a Muffle Furnace

It's helpful to compare a vacuum furnace to a muffle furnace. A muffle furnace isolates the workpiece from combustion byproducts by placing it in a separate chamber, but that chamber still contains air. It prevents contamination from a flame, but it does not prevent oxidation from the air itself.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the required outcome for your material.

- If your primary focus is achieving maximum material purity and preventing any surface oxidation: A vacuum furnace is the only reliable choice, as it is designed specifically to remove reactive gases.

- If your primary focus is simply protecting a part from direct flame or combustion gases: A muffle furnace can be a sufficient and more cost-effective solution, but you must accept that oxidation will occur.

- If your primary focus is precise control over the entire thermal cycle, including cooling: The advanced capabilities of a vacuum furnace, especially those with controlled gas quenching, offer unparalleled process control.

Ultimately, mastering heat treatment is about mastering the atmosphere, and a vacuum provides the ultimate level of atmospheric control.

Summary Table:

| Aspect | Mechanism | Benefit |

|---|---|---|

| Heat Transfer | Removes air to stop convection; relies on radiation | Enables precise, uniform heating without contact |

| Contamination Prevention | Creates inert environment by eliminating oxygen and reactive gases | Ensures material purity, prevents oxidation and scaling |

| Key Applications | Vacuum brazing, high-purity material processing | Ideal for processes requiring clean, strong bonds and integrity |

| Comparison to Muffle Furnace | No air removal vs. vacuum's inert atmosphere | Vacuum prevents oxidation; muffle only isolates from flames |

Unlock superior material purity and precise heat treatment with KINTEK's advanced vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more. Our deep customization capabilities ensure your unique experimental needs are met with precision. Contact us today to discuss how our high-temperature furnace solutions can enhance your processes and deliver contamination-free results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a vacuum drying oven required for Se/PPS composite treatment at 110°C? Ensure Chemical Purity & Bond Strength

- How does a high-precision vacuum drying oven contribute to the preparation of LiFePO4 electrode slurries?

- What are the environmental benefits of vacuum furnaces? Reduce Emissions and Boost Efficiency

- Why is a vacuum drying oven necessary for FTIR testing of lignite? Ensure Precision in Sample Dehydration

- What are the main benefits of using a vacuum furnace in industrial processes? Achieve Superior Quality and Efficiency

- What effects do nitrogen and argon cooling have on material properties? Optimize Hardness and Strength in Heat Treatment

- Why is degassing important in metal melting, and how does a vacuum help? Achieve Purer, Stronger Metal Alloys

- Why is a high-vacuum environment required before vacuum hot rolling? Ensure Superior Clad Plate Bonding Integrity