In the automotive industry, vacuum furnaces are essential for manufacturing high-performance metal components. They are used to perform critical heat treatment processes on parts like gears, engine components, bearings, and shafts. This controlled heating and cooling in a vacuum enhances material properties like hardness, strength, and wear resistance, which are vital for the durability and efficiency of modern vehicles.

The core function of a vacuum furnace in the automotive sector is to provide a perfectly controlled, oxygen-free environment for thermal processing. This prevents surface oxidation and contamination, resulting in stronger, more reliable, and higher-precision components than can be achieved with conventional atmosphere furnaces.

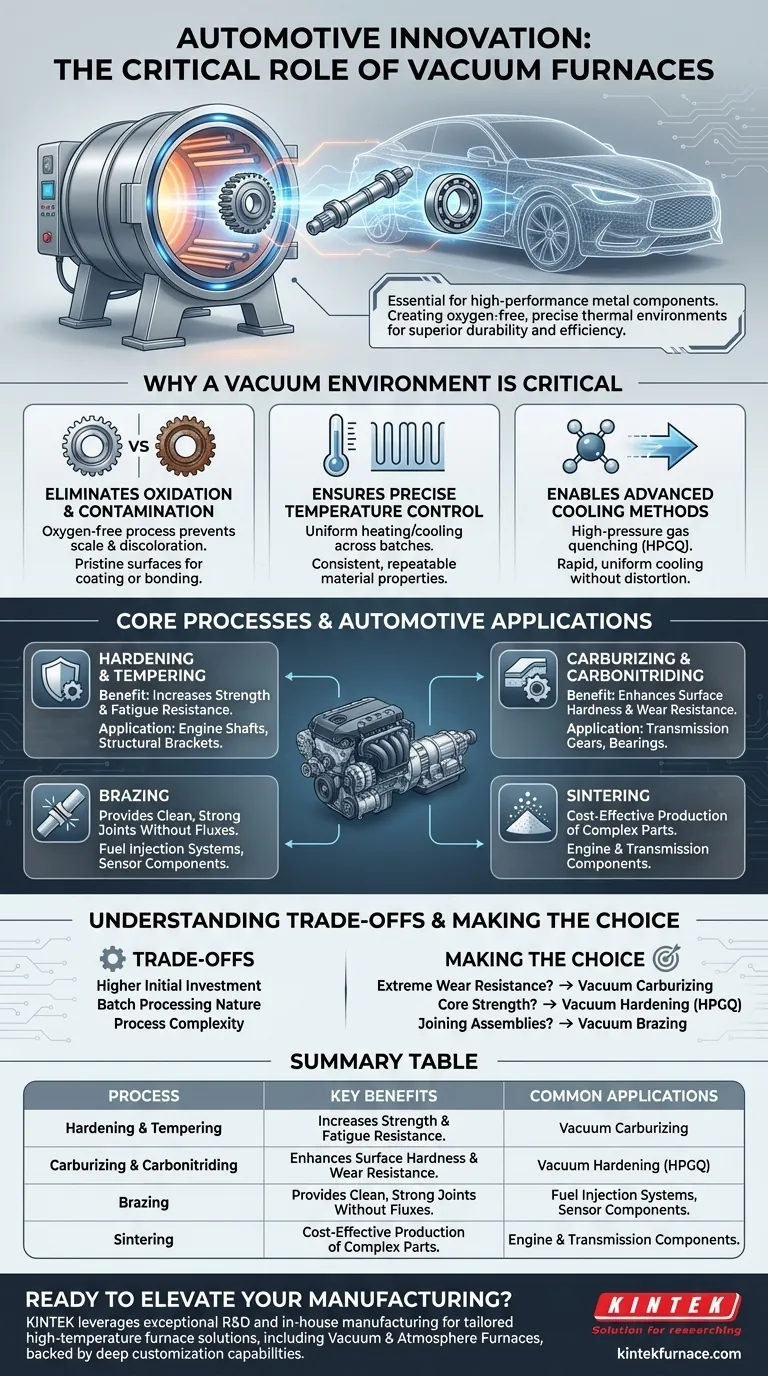

Why a Vacuum Environment is Critical

The "vacuum" in a vacuum furnace isn't just a detail; it's the key to achieving superior metallurgical properties. By removing air and other gases, the process gains significant advantages.

Eliminating Oxidation and Contamination

Heating metal to high temperatures in the presence of oxygen causes scale and discoloration, which can compromise surface integrity and dimensions. A vacuum environment eliminates this oxidation, resulting in clean, bright parts that often require no secondary cleaning.

This cleanliness is critical for parts that require a pristine surface for subsequent processes like coating or bonding.

Ensuring Precise Temperature Control

Vacuum furnaces offer exceptionally uniform temperature distribution. This ensures that the entire component, or batch of components, experiences the exact same thermal cycle from start to finish.

This precision is vital for achieving consistent and repeatable material properties, reducing part-to-part variation and scrap rates.

Enabling Advanced Cooling Methods

After heating, parts must be cooled (quenched) at a specific rate to lock in the desired hardness. Vacuum furnaces often use high-pressure gas quenching (HPGQ) with inert gases like nitrogen or argon.

This method provides rapid, uniform cooling without the distortion and environmental concerns associated with traditional oil quenching.

Core Processes and Their Applications

Automotive manufacturing leverages several key processes performed inside vacuum furnaces, each tailored to a specific outcome and component type.

Hardening and Tempering

This is the most common heat treatment for improving the strength and fatigue resistance of components subjected to high stress. Parts like engine shafts and structural brackets are heated and then rapidly quenched to create a hard, strong internal structure.

Carburizing and Carbonitriding

These are surface modification processes where carbon (and nitrogen in carbonitriding) is diffused into the surface of steel parts at high temperatures. This creates an extremely hard, wear-resistant outer layer while maintaining a softer, tougher core.

This dual property is ideal for high-wear components like transmission gears, ensuring they can withstand constant friction without becoming brittle.

Brazing

Vacuum brazing is a high-purity joining process used to bond metal parts together using a filler metal. In a vacuum, the filler metal flows cleanly and evenly into the joint without the need for corrosive fluxes.

This is used to create complex assemblies, such as joining dissimilar metals in fuel injection systems or sensor components, ensuring a strong and leak-proof bond.

Sintering

Sintering is the process of taking compacted metal powders and heating them in a vacuum furnace to bond the particles into a solid, near-net-shape part. This is a cost-effective method for producing complex components used in engines and transmissions.

Understanding the Trade-offs

While powerful, vacuum furnace technology involves specific considerations that make it ideal for some applications but less so for others.

Higher Initial Investment

Vacuum furnaces represent a significant capital investment compared to traditional atmosphere furnaces. Their advanced control systems, vacuum pumps, and robust chamber construction contribute to a higher upfront cost.

Batch Processing Nature

Most vacuum furnaces operate in batches. While individual cycle times can be fast, this batch nature differs from the continuous flow of some large-scale, lower-precision heat-treating operations.

Process Complexity

Operating a vacuum furnace requires a higher level of technical expertise. Process parameters like vacuum level, temperature ramps, and gas quench pressure must be precisely controlled to achieve the desired metallurgical outcome.

Making the Right Choice for Your Goal

The decision to use a specific vacuum furnace process is driven by the performance requirements of the final component.

- If your primary focus is extreme wear resistance for parts like gears: Vacuum carburizing is the optimal process for creating a hard case and a tough core.

- If your primary focus is improving the core strength of high-stress parts like shafts: Vacuum hardening with high-pressure gas quenching provides superior strength and minimizes distortion.

- If your primary focus is joining complex or dissimilar metal assemblies: Vacuum brazing delivers clean, strong, and flux-free joints that are vital for fluid and gas systems.

Ultimately, vacuum furnaces empower engineers to design and manufacture automotive parts that are lighter, stronger, and more reliable than ever before.

Summary Table:

| Process | Key Benefits | Common Automotive Applications |

|---|---|---|

| Hardening & Tempering | Increases strength and fatigue resistance | Engine shafts, structural brackets |

| Carburizing & Carbonitriding | Enhances surface hardness and wear resistance | Transmission gears, bearings |

| Brazing | Provides clean, strong joints without fluxes | Fuel injection systems, sensor components |

| Sintering | Enables cost-effective production of complex parts | Engine and transmission components |

Ready to elevate your automotive manufacturing with advanced vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're hardening gears or brazing complex assemblies, our expertise ensures superior performance and reliability. Contact us today to discuss how we can optimize your heat treatment processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability