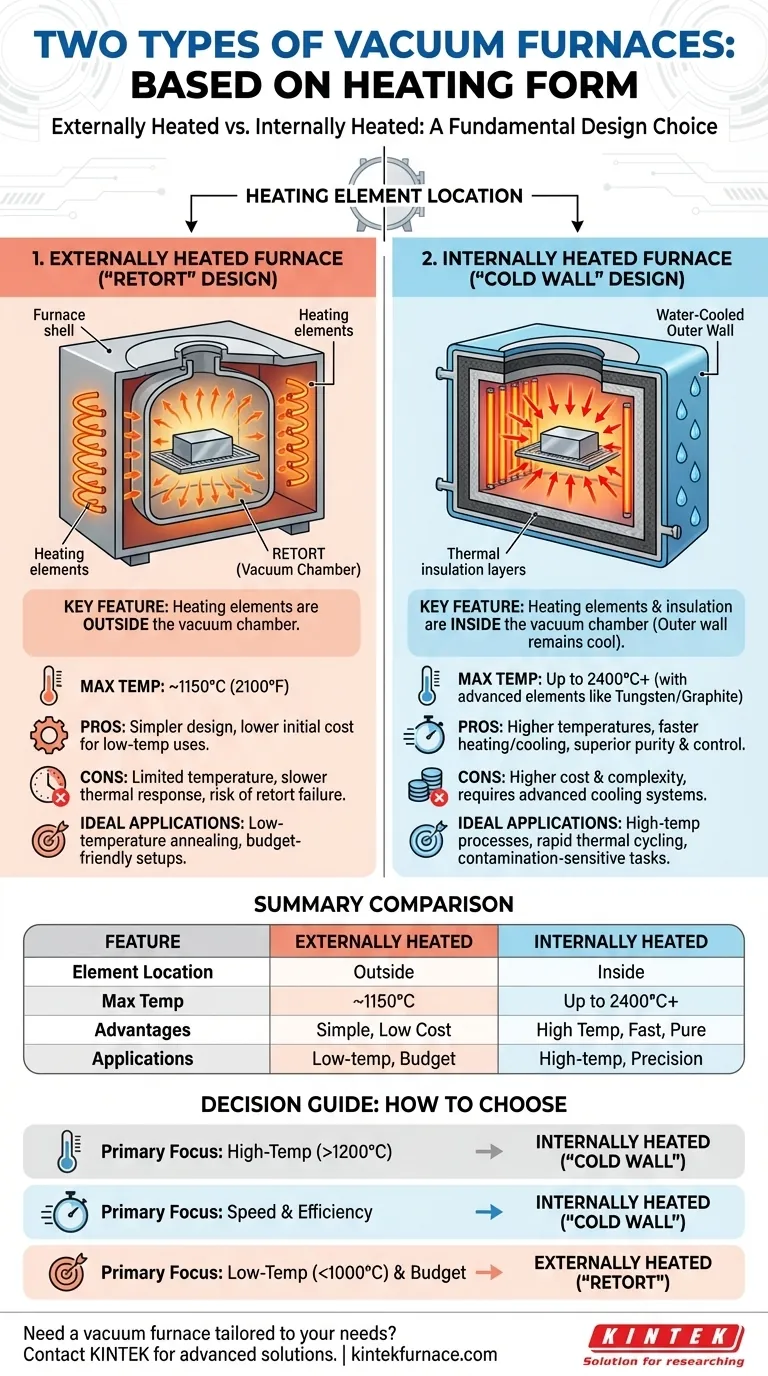

In terms of fundamental heating design, vacuum furnaces are classified into two primary types: externally heated and internally heated. In an externally heated furnace, the heating elements are outside the vacuum chamber, whereas in an internally heated furnace, the elements are located directly inside the vacuum-sealed environment.

While both designs exist, the choice between them is a critical engineering decision that dictates a furnace's temperature limits, efficiency, and cost. Modern high-performance applications overwhelmingly rely on the internally heated, or "cold wall," architecture.

The Two Core Heating Architectures

The location of the heating elements relative to the vacuum chamber is the most fundamental design difference in a vacuum furnace. This single choice has cascading effects on the furnace's capabilities and limitations.

Externally Heated Furnaces (The "Retort" Design)

In this design, the part to be processed is placed inside a sealed vessel, often called a retort. This entire vessel is then placed inside a larger furnace where heating elements on the outside heat the retort's walls, which in turn radiates heat to the part inside.

This method is mechanically simple but suffers from a significant limitation: the retort material itself must withstand both the high temperature and the external atmospheric pressure while maintaining a vacuum seal. This severely limits the maximum operating temperature, typically to around 1150°C (2100°F).

Internally Heated Furnaces (The "Cold Wall" Design)

This is the preferred and most common design for modern vacuum furnaces. The heating elements and thermal insulation are placed inside the vacuum chamber along with the workload.

The outer vessel wall is kept cool, usually with a water-cooling circuit, which is why it's called a "cold wall" design. Since the cool outer wall is not exposed to high temperatures, it can easily maintain its structural strength and the integrity of the vacuum seal.

Why Internal Heating Dominates Modern Furnaces

The shift toward internally heated designs is driven by the demand for higher temperatures and greater process control. The "cold wall" approach solves the core limitations of the external heating method.

Unlocking Higher Temperatures

This is the primary advantage. Because the structural chamber wall remains cool, the only thermal limit is the heating elements and insulation themselves.

Using materials like molybdenum allows for temperatures up to 1600°C. Advanced furnaces using graphite or tungsten heating elements can routinely exceed 2400°C, enabling processes that are impossible with external heating.

Faster Thermal Response

With heating elements inside the chamber, energy is transferred directly to the workload via radiation. This is far more efficient and faster than indirectly heating a massive retort wall.

Likewise, cooling can be accelerated by introducing an inert gas into the chamber, which is then circulated by a fan across the hot workload and cooled by the "cold wall."

Superior Purity and Control

By keeping the chamber walls cool, you minimize the risk of "outgassing"—the release of trapped molecules from the steel of the chamber itself. This results in a cleaner vacuum environment and less potential contamination of the parts being processed.

Understanding the Trade-offs

While the internally heated furnace is superior in performance, it comes with its own set of considerations. No single design is perfect for every possible scenario.

Cost and Complexity

A "cold wall" furnace is a more complex machine. It requires sophisticated water-cooling systems, specialized high-temperature heating elements that can operate in a vacuum, and multi-layer insulation packages made of materials like graphite felt. This complexity increases both the initial purchase price and maintenance costs.

The Niche for External Heating

For lower-temperature applications like tempering or annealing certain alloys, where temperatures do not exceed a few hundred degrees, an externally heated furnace can be a perfectly suitable and more economical solution. Its simplicity becomes an advantage when extreme performance is not required.

How to Apply This Knowledge

Understanding this fundamental design difference helps you decode furnace specifications and align them with your process needs.

- If your primary focus is high-temperature processing (>1200°C): An internally heated "cold wall" furnace is your only viable option.

- If your primary focus is process speed and efficiency: The direct energy transfer and rapid cooling capabilities of an internally heated furnace are essential.

- If your primary focus is a lower-temperature application (<1000°C) with a tight budget: An externally heated "retort" furnace may be a sufficient and more cost-effective choice.

Recognizing the distinction between internal and external heating is the first step toward selecting a vacuum furnace that aligns perfectly with your material, process, and performance goals.

Summary Table:

| Feature | Externally Heated Furnace | Internally Heated Furnace |

|---|---|---|

| Heating Element Location | Outside the vacuum chamber | Inside the vacuum chamber |

| Max Temperature | ~1150°C (2100°F) | Up to 2400°C+ with advanced elements |

| Key Advantages | Simpler design, lower cost for low-temp uses | Higher temperatures, faster heating/cooling, superior purity |

| Ideal Applications | Low-temperature annealing, budget-friendly setups | High-temperature processes, rapid thermal cycling, contamination-sensitive tasks |

Need a vacuum furnace tailored to your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements, enhancing efficiency and performance. Contact us today to discuss how we can support your high-temperature processing goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties