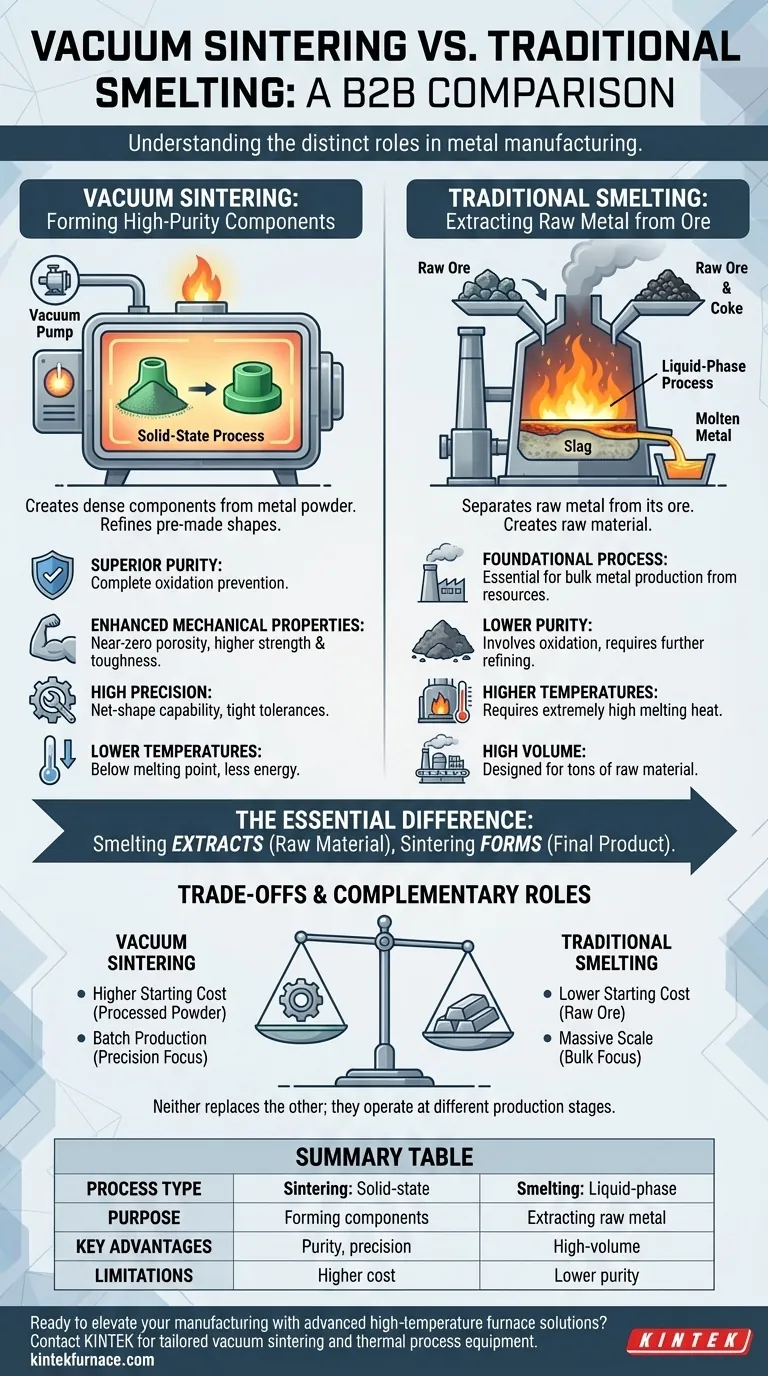

At its core, vacuum sintering is a sophisticated solid-state manufacturing process for creating high-purity, dense components from metal powder, while traditional smelting is a liquid-phase extractive process designed to separate raw metal from its ore. Sintering refines a pre-made shape, whereas smelting creates the raw material itself.

The essential difference is one of purpose, not direct competition. Smelting is the foundational process for extracting metal from natural ore. Vacuum sintering is an advanced manufacturing technique for forming already-refined metal powders into a final, high-performance product.

Understanding the Fundamental Processes

To compare these methods effectively, we must first define their distinct roles in the lifecycle of a metal product. They operate at entirely different stages of production and solve different engineering problems.

What is Traditional Smelting?

Smelting is a form of extractive metallurgy. It involves melting raw ore in a furnace at extremely high temperatures along with a chemical reducing agent, such as coke.

This process triggers a chemical reaction that separates the molten base metal from the unwanted impurities, which are removed as a separate layer called slag. The output is a large volume of raw, unrefined metal.

What is Vacuum Sintering?

Vacuum sintering is a powder metallurgy technique. It begins with a fine, purified metal powder that is first pressed into a desired shape, known as a "green part."

This part is then heated in a high-vacuum furnace to a temperature just below its melting point. At this temperature, the individual powder particles fuse together, eliminating the pores between them and forming a dense, solid, and strong final component.

Key Advantages of Vacuum Sintering for Manufacturing

For the task of creating a finished part, vacuum sintering offers significant advantages over any process that involves melting, including those derived from smelted materials.

Superior Purity and Material Quality

The vacuum environment is the most critical factor. By removing air and other gases, it completely prevents oxidation and eliminates reactions between the metal and its atmosphere during heating.

This results in an exceptionally clean material, free from the gas-related impurities and oxide inclusions that can compromise performance in traditional casting methods.

Enhanced Mechanical Properties and Density

The vacuum actively pulls trapped gases out from between the powder particles, promoting superior densification.

This leads to final parts with near-zero porosity, resulting in significantly increased strength, toughness, and fatigue resistance compared to parts made by other methods.

High Precision and Net-Shape Capability

Because the material never fully melts, it holds its shape with exceptional accuracy. Vacuum sintering prevents the uncontrolled shrinkage and distortion common in casting.

This allows for the creation of complex, net-shape or near-net-shape parts with excellent dimensional tolerances and a smooth surface finish, minimizing the need for costly secondary machining.

Lower Processing Temperatures

Sintering occurs below the material's melting point, requiring substantially less energy than smelting or casting. This not only saves energy but also reduces thermal stress on furnace components, extending their operational life.

Understanding the Trade-offs and Limitations

Choosing a process requires acknowledging its practical and economic boundaries. Neither technology replaces the other; they serve complementary functions.

The Role of Smelting is Irreplaceable

You cannot perform vacuum sintering without a source of high-purity metal powder. That powder is most often created from metal that was originally produced via smelting.

Smelting is the foundational industrial process for producing metal at scale from the earth's natural resources. It is the beginning of the material supply chain.

Cost and Starting Material

Vacuum sintering requires a highly processed input: clean, consistently sized metal powder. This powder is a valuable manufactured product in its own right, making the starting material cost significantly higher than that of raw ore for smelting.

Scale of Production

Smelting is designed for massive, continuous production of bulk raw material, measured in tons. Vacuum sintering is better suited for producing batches of precise, high-value components, from single parts to thousands of units. It is not a method for bulk metal production.

Making the Right Choice for Your Goal

Your application's objective determines the correct technology. The decision becomes clear when you define the problem you are trying to solve.

- If your primary focus is producing raw metal from ore: Smelting is the essential, non-negotiable industrial process for this task.

- If your primary focus is creating high-purity, complex parts with precise dimensions: Vacuum sintering is the superior technology for manufacturing finished components from refined metal powders.

Understanding this distinction transforms the question from "which is better" to "which stage of the manufacturing lifecycle are you targeting?"

Summary Table:

| Aspect | Vacuum Sintering | Traditional Smelting |

|---|---|---|

| Process Type | Solid-state powder metallurgy | Liquid-phase extractive metallurgy |

| Purpose | Forming high-purity, dense components from metal powder | Extracting raw metal from ore |

| Key Advantages | Superior purity, enhanced mechanical properties, high precision, lower temperatures | High-volume raw metal production, foundational for metal supply chain |

| Limitations | Higher starting material cost, not for bulk production | Lower purity, involves oxidation, higher energy for melting |

Ready to elevate your manufacturing with advanced high-temperature furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need vacuum sintering for high-purity components or other thermal processes, we deliver reliable, efficient, and customized equipment. Contact us today to discuss how we can optimize your production and achieve superior results!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery

- Why is a high-vacuum environment necessary in copper slag impoverishment? Maximize Your Matte Separation Efficiency