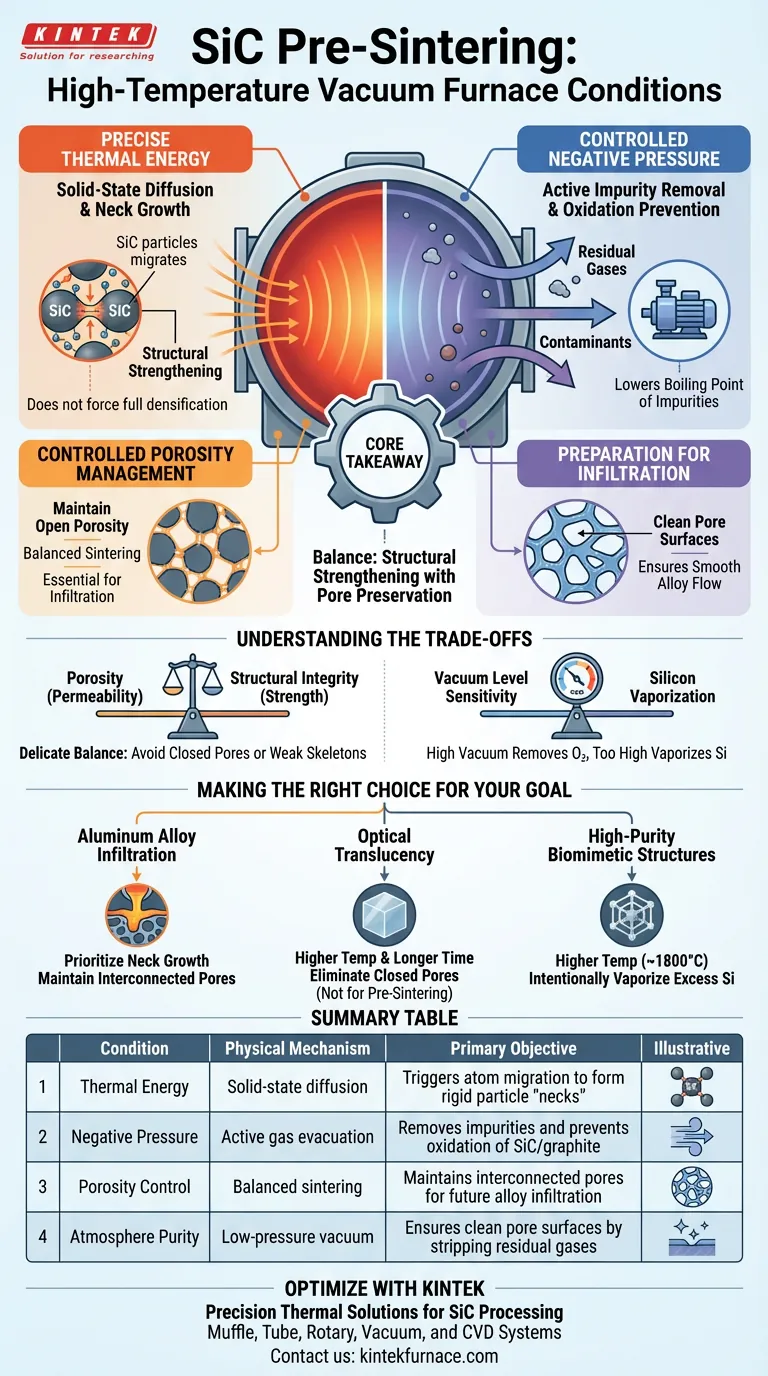

A high-temperature vacuum furnace establishes a dual-condition environment defined by precise thermal energy and controlled negative pressure. During the pre-sintering of Silicon Carbide (SiC) skeletons, this environment facilitates solid-state diffusion and "neck growth" between particles without forcing full densification. Simultaneously, the low-pressure atmosphere actively evacuates residual gases from the material's pores to prevent contamination.

Core Takeaway The primary function of the furnace during this specific process is to balance structural strengthening with pore preservation. By driving particle bonding while maintaining open porosity, the system creates a rigid, clean ceramic network specifically engineered for successful aluminum alloy infiltration.

The Mechanisms of Skeleton Formation

Solid-State Diffusion

The furnace creates a high-temperature regime that energizes the atoms within the SiC powder.

This thermal energy triggers solid-state diffusion, a physical process where atoms migrate across the boundaries of adjacent particles.

Particle Neck Growth

As diffusion occurs, "necks" or bridges form at the contact points between SiC particles.

This neck growth transforms the loose powder into a cohesive, rigid framework (the skeleton) without melting the material.

Controlled Porosity Management

Unlike standard sintering, the goal here is not to eliminate voids but to stabilize them.

By strictly regulating the temperature and duration, the furnace ensures the skeleton retains a specific pore size distribution and interconnected porosity, which is essential for subsequent processing.

The Role of the Vacuum Environment

Active Impurity Removal

The vacuum environment acts as a cleaning mechanism, lowering the boiling point of volatile impurities.

It effectively strips away residual gases trapped within the pores and removes contaminants adsorbed on the powder surfaces.

Prevention of Oxidation

At high temperatures, SiC and the graphite molds used in processing are highly susceptible to oxidation.

The vacuum eliminates oxygen and moisture from the chamber, preserving the chemical purity of the ceramic and the integrity of the tooling.

Preparation for Infiltration

By removing gas pockets and preventing oxide layer formation, the vacuum ensures the final pore structure is "clean."

This allows for the smooth infiltration of molten aluminum alloys in later stages, as there are no trapped gases to block the metal flow.

Understanding the Trade-offs

Porosity vs. Structural Integrity

There is a delicate balance between the strength of the skeleton and its permeability.

If the sintering temperature is too high or held too long, the pores may close off, preventing alloy infiltration. Conversely, insufficient heat results in a weak skeleton that may collapse during infiltration.

Vacuum Level Sensitivity

While a vacuum is essential for purity, the specific pressure level dictates the efficiency of impurity removal.

Extremely high vacuums effectively remove oxygen but, at extreme temperatures (e.g., nearing 1800°C), can induce the vaporization of silicon itself, potentially altering the stoichiometry of the material if not monitored.

Making the Right Choice for Your Goal

To optimize the pre-sintering of your SiC skeleton, align your furnace parameters with your specific end-use requirements:

- If your primary focus is Aluminum Alloy Infiltration: Prioritize "neck growth" over densification to maintain an open, interconnected pore network.

- If your primary focus is Optical Translucency: You must utilize higher temperatures and longer hold times to eliminate closed pores, though this is generally not the goal for pre-sintered skeletons.

- If your primary focus is High-Purity Biomimetic Structures: Utilize higher temperatures (approx. 1800°C) to intentionally vaporize and remove excess residual silicon impurities.

Success depends on using the vacuum not just to heat the material, but to sculpt the empty space within it.

Summary Table:

| Condition | Physical Mechanism | Primary Objective |

|---|---|---|

| Thermal Energy | Solid-state diffusion | Triggers atom migration to form rigid particle "necks" |

| Negative Pressure | Active gas evacuation | Removes impurities and prevents oxidation of SiC/graphite |

| Porosity Control | Balanced sintering | Maintains interconnected pores for future alloy infiltration |

| Atmosphere Purity | Low-pressure vacuum | Ensures clean pore surfaces by stripping residual gases |

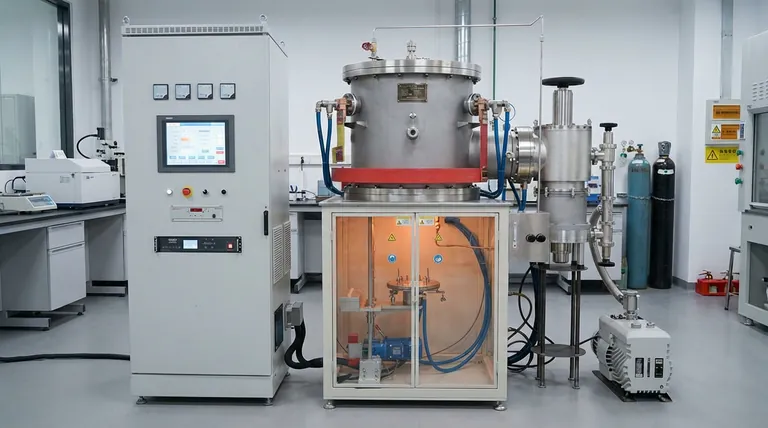

Optimize Your SiC Sintering with KINTEK

Precision matters when balancing structural integrity and interconnected porosity in your ceramic skeletons. KINTEK provides industry-leading thermal solutions backed by expert R&D and advanced manufacturing. Our range of Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet the exacting temperature and pressure demands of Silicon Carbide processing.

Whether you are preparing skeletons for aluminum alloy infiltration or developing high-purity biomimetic structures, our high-temp furnaces ensure clean, consistent, and high-performance results.

Ready to elevate your lab's output? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Arash Kariminejad, Mart Viljus. Effect of thermal shock treatment parameters on the efficiency of WC-Co cermet recycling. DOI: 10.1063/5.0189330

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a vacuum drying oven required for processing ball-milled red mud-alumina powder? Essential Drying Facts

- Why does the simulation of magnesium alloy distillation require high precision? Master Vacuum for Purity

- Why is graphite the material of choice for vacuum furnaces? Unmatched Performance in Extreme Heat

- Why is a high-vacuum sintering furnace required for ADAM? Unlock High-Density Metal 3D Printing Results

- What is the regulatory function of a vacuum drying oven? Master Catalyst Preparation and Distribution Control

- How do multiple-chamber vacuum furnaces enhance productivity? Boost Throughput with Continuous Workflow

- What is the primary function of a vacuum drying oven in the synthesis of H2bdt organic ligands? Protect Your Purity.

- What role does a high-temperature furnace play in CsPbCl3-MSN synthesis? Mastering Thermal Encapsulation