At their core, multiple-chamber vacuum furnaces enhance productivity by transforming a linear batch process into a continuous, parallel workflow. Instead of a single chamber handling every step—heating, quenching, and cooling—these systems dedicate separate chambers to specific tasks. This allows a new load to begin heating immediately while the previous one cools, dramatically reducing non-productive downtime.

The fundamental advantage of a multi-chamber furnace is the elimination of the cool-down/reheat cycle for the primary heating chamber. By keeping the hot zone continuously hot and under vacuum, you remove the two biggest time and energy sinks in the vacuum heat-treating process, leading to a significant increase in throughput.

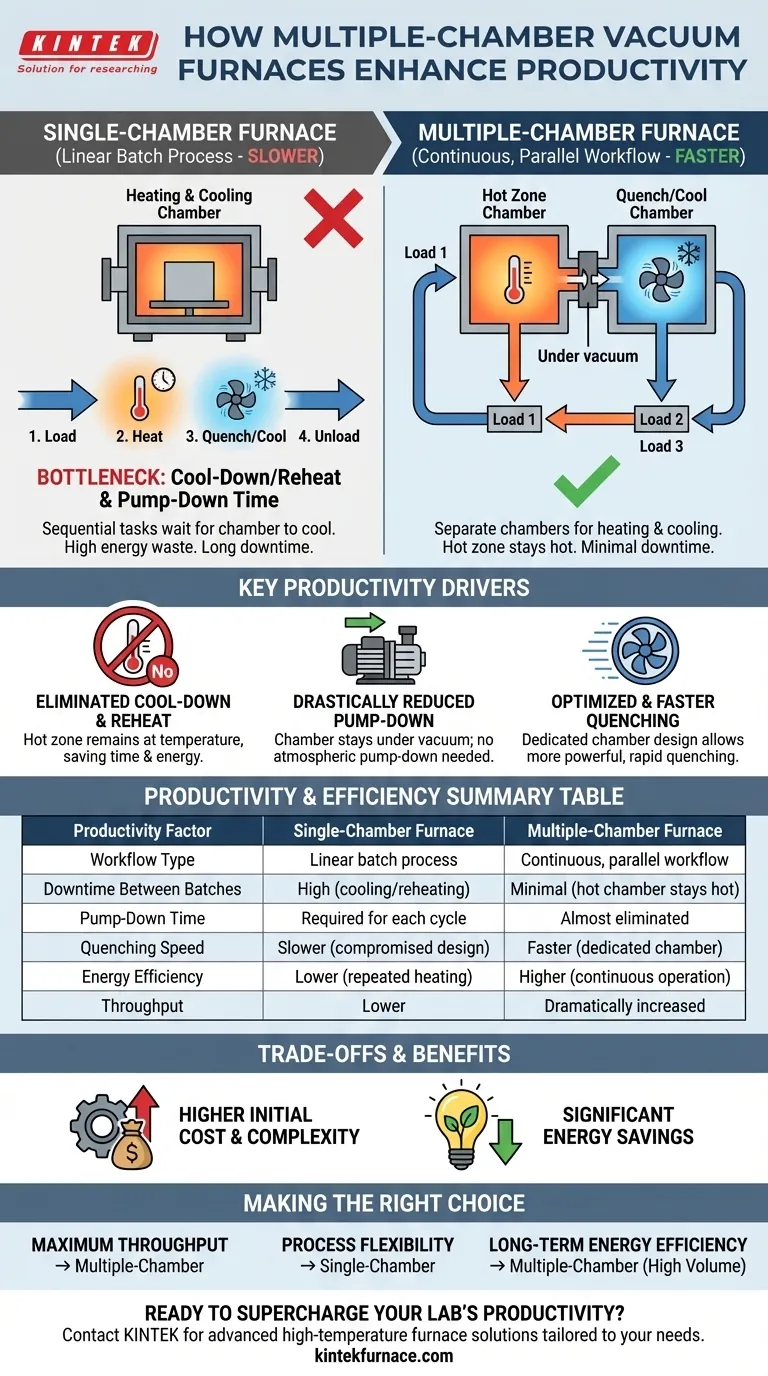

The Core Advantage: Eliminating the Batch Bottleneck

To understand the multi-chamber advantage, you must first recognize the inherent limitations of a single-chamber design.

The Single-Chamber Limitation

A traditional single-chamber furnace operates sequentially. The entire vessel must be heated for the treatment cycle, then used for quenching, and finally cooled down before the doors can be opened to remove the processed load. This entire cycle of heating and cooling the chamber itself represents wasted time and energy.

The Multi-Chamber Workflow

Multiple-chamber furnaces break this linear sequence. A typical two-chamber system consists of a hot chamber and a cooling/quenching chamber. A load is heated in the first chamber, then transferred under vacuum to the second chamber for quenching.

Crucially, as soon as the first load vacates the hot chamber, the next load can immediately enter. The hot chamber never cools down and is never exposed to atmosphere, sidestepping the biggest bottlenecks of the single-chamber process.

Key Mechanisms Driving Productivity Gains

The productivity increase isn't just theoretical; it's the result of specific engineering advantages that compound to shorten the overall cycle time per part.

Drastically Reduced Pump-Down Time

Because the hot chamber remains sealed and under vacuum between loads, the furnace does not need to pump down from atmospheric pressure for each new cycle. This step, which can be time-consuming in large single-chamber units, is almost entirely eliminated, saving significant time on every batch.

Optimized and Faster Quenching

A dedicated cooling chamber can be engineered specifically for rapid quenching. It isn't a compromise design trying to also serve as a heating chamber. This allows for more powerful and efficient gas circulation systems, increasing quench speed and further reducing the total processing time.

Minimal Downtime Between Batches

The combination of immediate reloading, eliminated pump-down, and faster quenching results in minimal downtime between loads. This transforms the operation into a semi-continuous flow, maximizing the number of batches that can be processed in a given period and dramatically increasing furnace throughput.

Understanding the Trade-offs and Energy Benefits

While productivity is the primary driver, the operational benefits extend to energy consumption, though it's important to recognize the associated complexities.

Significant Energy Savings

Maintaining the hot zone at temperature is far more energy-efficient than reheating it from a cooled state for every single batch. Heat is used almost exclusively for treating the workpiece, not for repeatedly heating the furnace infrastructure. This provides substantial energy savings in high-volume production environments.

Higher Initial Cost and Complexity

The primary trade-off is capital investment and complexity. Multiple-chamber systems have a larger footprint, more moving parts (like internal transfer mechanisms), and a higher initial purchase price than single-chamber furnaces of a similar capacity. Their value is realized through high utilization and throughput.

Modern Efficiency Features

These advanced furnaces often incorporate other energy-saving technologies. Variable frequency drives (VFDs) can optimize the power consumption of pumps and fans, while regenerative cooling systems can capture and recycle waste heat, further improving overall operational efficiency.

Making the Right Choice for Your Operation

The decision to use a multiple-chamber furnace depends entirely on your production goals and operational scale.

- If your primary focus is maximum throughput: A multiple-chamber furnace is the definitive choice for high-volume, continuous production runs where minimizing cycle time is critical.

- If your primary focus is process flexibility for varied, small batches: A single-chamber furnace may offer a more practical and cost-effective solution for job shops or R&D environments.

- If your primary focus is long-term energy efficiency: A multiple-chamber furnace provides significant operational cost savings, but only if your production volume is high enough to justify the initial investment.

Ultimately, choosing the right furnace technology is about aligning the equipment's core strengths with your specific production demands.

Summary Table:

| Productivity Factor | Single-Chamber Furnace | Multiple-Chamber Furnace |

|---|---|---|

| Workflow Type | Linear batch process | Continuous, parallel workflow |

| Downtime Between Batches | High (due to cooling/reheating) | Minimal (hot chamber stays hot) |

| Pump-Down Time | Required for each cycle | Almost eliminated |

| Quenching Speed | Slower (compromised design) | Faster (dedicated chamber) |

| Energy Efficiency | Lower (repeated heating) | Higher (continuous operation) |

| Throughput | Lower | Dramatically increased |

Ready to supercharge your lab's productivity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're aiming for maximum throughput or energy efficiency, our multiple-chamber vacuum furnaces can transform your operations. Contact us today to discuss how we can enhance your productivity and deliver reliable, high-performance solutions!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What is the maximum sample size that the 3-Zone tube furnace can accommodate? Optimize for Uniform Heating and CVD

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations