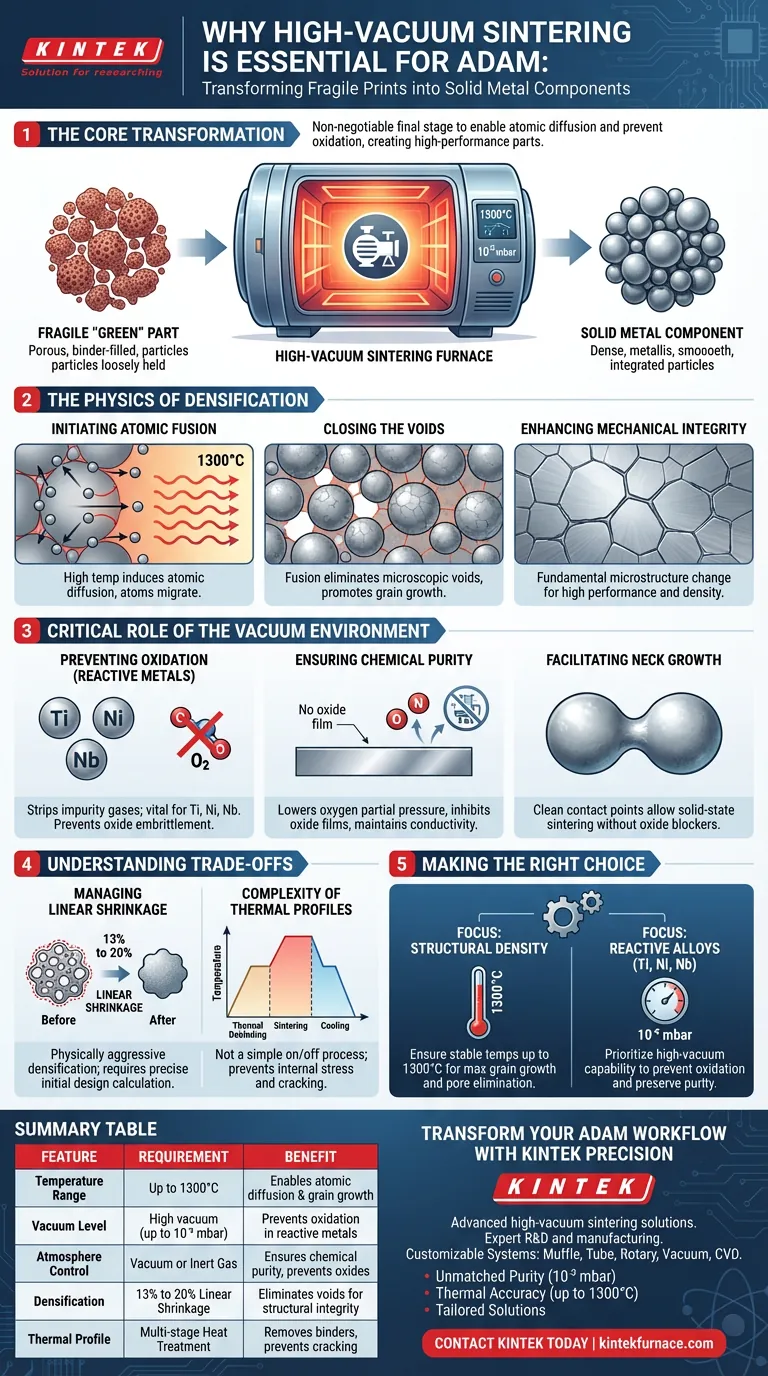

A high-vacuum sintering furnace is the non-negotiable final stage in the Atomic Diffusion Additive Manufacturing (ADAM) process because it transforms a fragile, binder-filled print into a solid metal component. By reaching extreme temperatures up to 1300°C in a controlled vacuum or inert atmosphere, the furnace enables atomic diffusion to fuse metal particles together while strictly preventing oxidation.

The furnace acts as a crucible for material transformation, creating a contaminant-free environment where metal particles merge at the atomic level. This eliminates voids and residual binders, bridging the gap between a printed "green" part and a final component with high mechanical performance and near-full density.

The Physics of Densification

Initiating Atomic Fusion

The primary function of the sintering furnace is to induce atomic diffusion. By raising the temperature to levels near the melting point of the metal—often up to 1300°C—the thermal energy causes metal atoms to migrate across particle boundaries.

Closing the Voids

As the metal powder particles fuse, the material undergoes significant densification. The furnace environment promotes grain boundary growth, which systematically eliminates the microscopic voids originally occupied by the binding agent.

Enhancing Mechanical Integrity

This fusion process does more than just harden the part; it fundamentally changes its microstructure. The result is a solid metal component that possesses the high mechanical performance and structural density required for functional engineering applications.

The Critical Role of the Vacuum Environment

Preventing Oxidation in Reactive Metals

Standard heating causes immediate oxidation in metals like titanium (Ti), nickel (Ni), and niobium (Nb). A high-vacuum environment—capable of reaching pressures as low as 10⁻⁵ mbar—is essential to strip away impurity gases and oxygen.

Ensuring Chemical Purity

Oxygen and nitrogen are highly reactive at sintering temperatures. The vacuum environment lowers the oxygen partial pressure to inhibit the formation of oxide films, which would otherwise compromise the material's electrical conductivity and phase structure.

Facilitating Neck Growth

For atomic diffusion to occur, particles must form "necks" or connection points. A vacuum ensures these contact points remain pure, allowing solid-state sintering to proceed without oxide layers blocking the connection between particles.

Understanding the Trade-offs

Managing Linear Shrinkage

The densification process is physically aggressive. As voids are removed and particles pull together, the part experiences linear shrinkage of 13% to 20%. This volume change must be perfectly calculated during the initial design phase to ensure dimensional accuracy.

Complexity of Thermal Profiles

Sintering is not a simple "on/off" heating process. The furnace must execute complex heat treatment profiles, transitioning carefully from thermal debinding (removing residual binder) to high-temperature sintering to prevent internal stress or cracking.

Making the Right Choice for Your Goal

Achieving the optimal result in ADAM processing depends on matching your furnace capabilities to your material requirements.

- If your primary focus is Structural Density: Ensure your furnace can maintain stable temperatures up to 1300°C to maximize grain boundary growth and eliminate internal porosity.

- If your primary focus is Reactive Alloys (Ti, Ni, Nb): Prioritize a furnace capable of high-vacuum levels (10⁻⁵ mbar) to prevent oxide embrittlement and preserve chemical purity.

The high-vacuum sintering furnace is not merely an oven; it is the precision instrument that dictates the final mechanical reality of your manufactured part.

Summary Table:

| Feature | Requirement in ADAM Process | Benefit to Final Metal Part |

|---|---|---|

| Temperature Range | Up to 1300°C | Enables atomic diffusion and grain boundary growth |

| Vacuum Level | High vacuum (up to 10⁻⁵ mbar) | Prevents oxidation and embrittlement in reactive metals |

| Atmosphere Control | Vacuum or Inert Gas | Ensures chemical purity and prevents oxide film formation |

| Densification | 13% to 20% Linear Shrinkage | Eliminates voids for high structural integrity |

| Thermal Profile | Multi-stage Heat Treatment | Removes binders and prevents internal cracking |

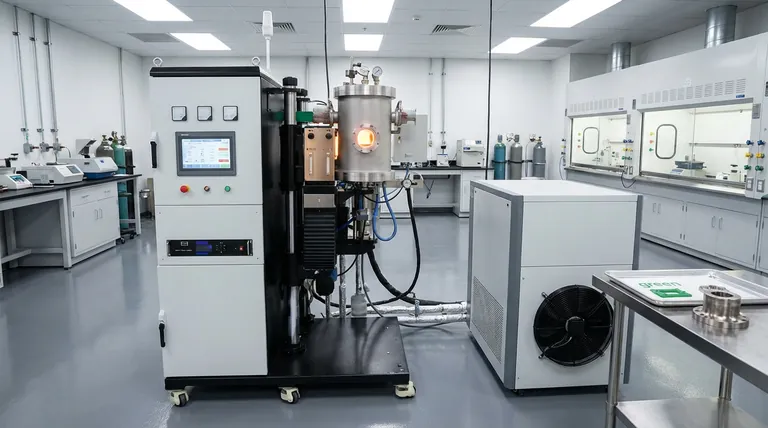

Transform Your ADAM Workflow with KINTEK Precision

Transition from a fragile 'green' part to a high-performance metal component with KINTEK’s advanced high-vacuum sintering solutions. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of atomic diffusion and material densification.

Why choose KINTEK for your lab?

- Unmatched Purity: Achieve vacuum levels down to 10⁻⁵ mbar to protect reactive alloys like Titanium and Nickel.

- Thermal Accuracy: Precise control up to 1300°C for consistent shrinkage and mechanical integrity.

- Tailored Solutions: Equipment customized for your unique high-temperature research or production needs.

Ready to elevate your material science? Contact KINTEK today to discuss your furnace requirements!

Visual Guide

References

- Andrej Czán, Dominik Krišák. Analysis of the Basic Characteristics of the Working Accuracy of the Atomic Diffusion Additive Manufacturing ADAM Process by Comparison with the Selective Laser Melting SLM Process. DOI: 10.21062/mft.2024.015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- In which industries is vacuum brazing commonly applied? Essential for Aerospace, Medical, Automotive, and Electronics

- What is vacuum sintering and its significance? Achieve Superior Material Performance

- Why is vacuum heat treatment the optimum method for certain alloys? Prevent Oxidation and Decarburization for Superior Performance

- Why is low-temperature calcination in a vacuum furnace necessary for Yb:CaF2 nanopowders? Achieve Optical Perfection

- What are the characteristics, advantages, and disadvantages of a vacuum sintering furnace? Maximize Material Purity and Performance

- Why is joint clearance important in vacuum brazing? Ensure Strong, Reliable Bonds

- How do the operation and maintenance features of vacuum sintering furnaces enhance efficiency? Boost Productivity and Cut Costs

- What are the advantages of using heat treatment and vacuum furnaces? Achieve Superior Material Quality and Control