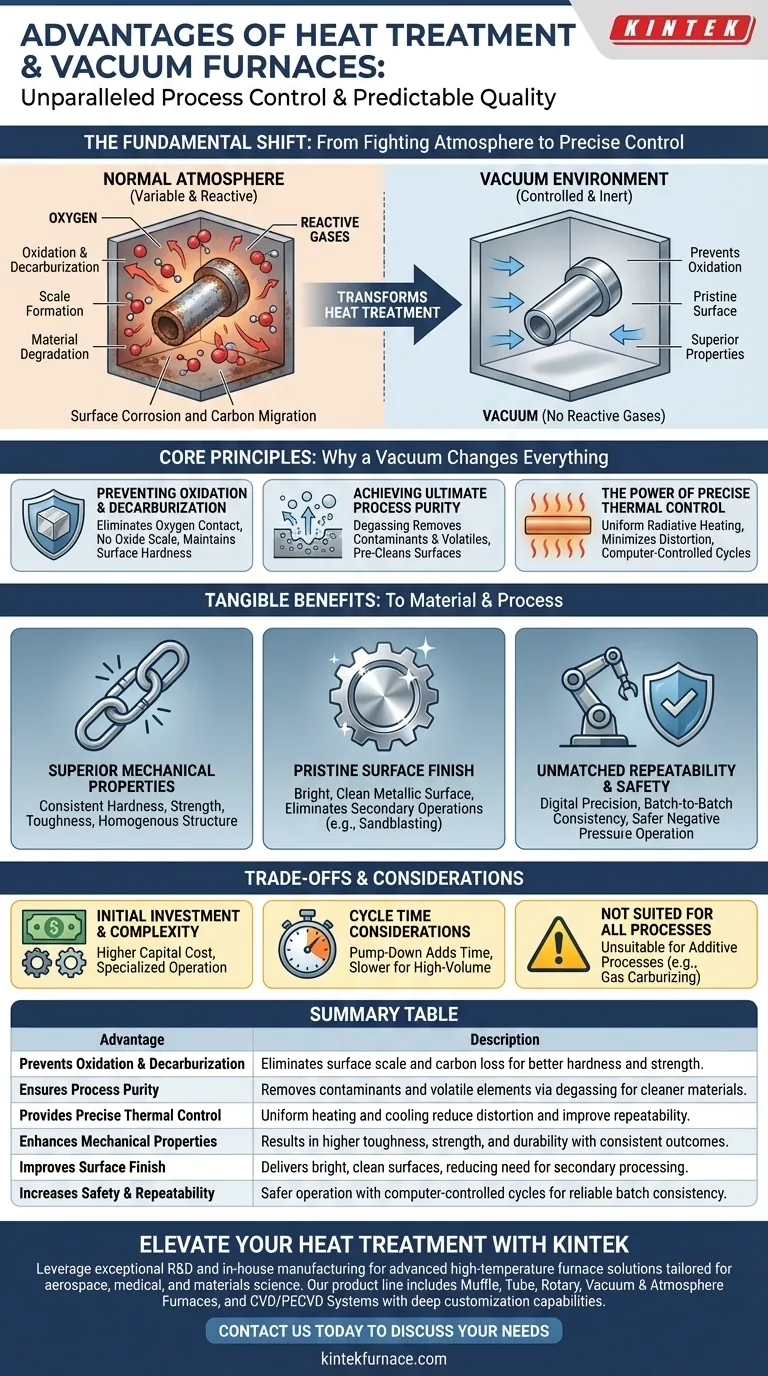

The fundamental advantage of using a vacuum furnace for heat treatment is unparalleled process control. This control is achieved by removing the reactive gases found in a normal atmosphere. By operating in a vacuum, you prevent unwanted chemical reactions like oxidation, which directly leads to superior material properties, pristine surface quality, enhanced process purity, and exceptional consistency between batches.

A vacuum furnace transforms heat treatment by removing the variable of atmospheric reaction. Instead of fighting against oxidation and contamination, you gain precise control over the material's thermal journey, resulting in higher quality, more consistent, and predictable outcomes.

Why a Vacuum Changes Everything: The Core Principles

To understand the benefits, you must first understand why removing the atmosphere is so critical. At the high temperatures required for heat treatment, metals become highly reactive with the gases around them, primarily oxygen. A vacuum furnace mitigates this fundamental problem.

Preventing Oxidation and Decarburization

At elevated temperatures, oxygen aggressively bonds with a metal's surface, creating a layer of oxide scale. This not only ruins the surface finish but can also alter the dimensions of a precision part.

Simultaneously, a process called decarburization can occur, where carbon atoms migrate from the surface of steel. This leaves the surface layer softer and weaker than the core, compromising the component's performance and fatigue life. A vacuum environment, being nearly devoid of oxygen and other reactive gases, prevents both of these destructive reactions from occurring.

Achieving Ultimate Process Purity

A vacuum does more than just prevent contamination; it actively cleans the workpiece. The negative pressure environment helps pull volatile elements, such as phosphorus, and trapped gases out of the material's surface in a process known as degassing.

This results in a purer, higher-integrity material structure and removes surface oils or residues without the need for separate, pre-cleaning chemical processes.

The Power of Precise Thermal Control

With no air to transfer heat via convection, heating in a vacuum is dominated by radiation. This allows for extremely uniform temperature distribution across the workpiece, minimizing internal stresses and distortion.

Furthermore, modern vacuum furnaces allow for computer-controlled heating and cooling (quenching) cycles. This digital precision ensures that every part in every batch receives the exact same thermal treatment, leading to unmatched repeatability.

The Tangible Benefits to Your Material and Process

The principles of operating in a vacuum translate directly into significant, measurable improvements in your final product and overall operation.

Superior Mechanical Properties

By preventing decarburization, the material's surface retains its specified hardness and strength. The uniform heating and controlled cooling produce a more homogenous grain structure throughout the component, leading to more predictable and reliable improvements in toughness, strength, and durability.

Pristine Surface Finish

Parts treated in a vacuum furnace emerge with a bright, clean, and metallic surface. Because no oxide scale forms, you often eliminate the need for costly and time-consuming secondary operations like sandblasting, chemical pickling, or grinding.

Unmatched Repeatability and Safety

Computer-controlled cycles remove the guesswork and variability inherent in older methods. A vacuum process is highly repeatable, which is critical for industries like aerospace and medical where quality control is non-negotiable.

Operationally, vacuum furnaces are inherently safer. They operate at negative pressure, eliminating the risk of explosion associated with pressurized vessels. The low-oxygen environment also removes the risk of fire.

Understanding the Trade-offs and Considerations

While powerful, vacuum furnace technology is not the universal solution for every application. Objectivity requires acknowledging its limitations.

Initial Investment and Complexity

Vacuum furnaces represent a significant capital investment compared to conventional atmosphere furnaces. They also require more specialized knowledge for operation and maintenance due to their high-vacuum pumps, seals, and control systems.

Cycle Time Considerations

The process of pumping the chamber down to the required vacuum level adds time to the overall treatment cycle. For some high-volume, low-specification parts, the faster cycle time of a continuous atmosphere furnace may be more economical.

Not Suited for All Processes

Some heat treatment processes, such as gas carburizing or nitriding, fundamentally require a specific, chemically active atmosphere to donate carbon or nitrogen atoms to the material's surface. A pure vacuum is unsuitable for these additive processes, though hybrid systems do exist.

Making the Right Choice for Your Application

Selecting the right heat treatment technology depends entirely on the required outcome for your component.

- If your primary focus is material integrity and performance: Vacuum treatment is the superior choice for preventing oxidation and achieving consistent, high-end mechanical properties.

- If your primary focus is surface finish and reducing post-processing: The bright, clean finish from a vacuum furnace can eliminate secondary steps, directly saving time and operational costs.

- If your primary focus is process repeatability for critical components: The computer-controlled, inert environment of a vacuum furnace offers unmatched consistency from batch to batch.

- If your primary focus is high-volume, low-cost production: Carefully evaluate if the cycle times and initial investment of vacuum technology align with your cost model, as a traditional atmosphere furnace may be more economical.

Ultimately, choosing vacuum heat treatment is an investment in process control and predictable quality.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation & Decarburization | Eliminates surface scale and carbon loss for better hardness and strength. |

| Ensures Process Purity | Removes contaminants and volatile elements via degassing for cleaner materials. |

| Provides Precise Thermal Control | Uniform heating and cooling reduce distortion and improve repeatability. |

| Enhances Mechanical Properties | Results in higher toughness, strength, and durability with consistent outcomes. |

| Improves Surface Finish | Delivers bright, clean surfaces, reducing need for secondary processing. |

| Increases Safety & Repeatability | Safer operation with computer-controlled cycles for reliable batch consistency. |

Ready to elevate your heat treatment processes with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, medical, and materials science. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our vacuum furnaces can enhance your material quality, reduce costs, and ensure unmatched consistency in your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today