A vacuum sintering furnace is an advanced heat treatment system that sinters materials in a controlled, low-pressure environment. Its primary advantage is the ability to produce exceptionally pure, dense, and high-performance components by preventing atmospheric contamination like oxidation. However, this level of quality comes at a significant cost, both in the initial equipment investment and the specialized knowledge required for its operation.

The core decision to use a vacuum sintering furnace is a trade-off: you are investing in a more complex and expensive process to achieve a level of material purity and structural integrity that is simply not possible with conventional atmosphere-based furnaces.

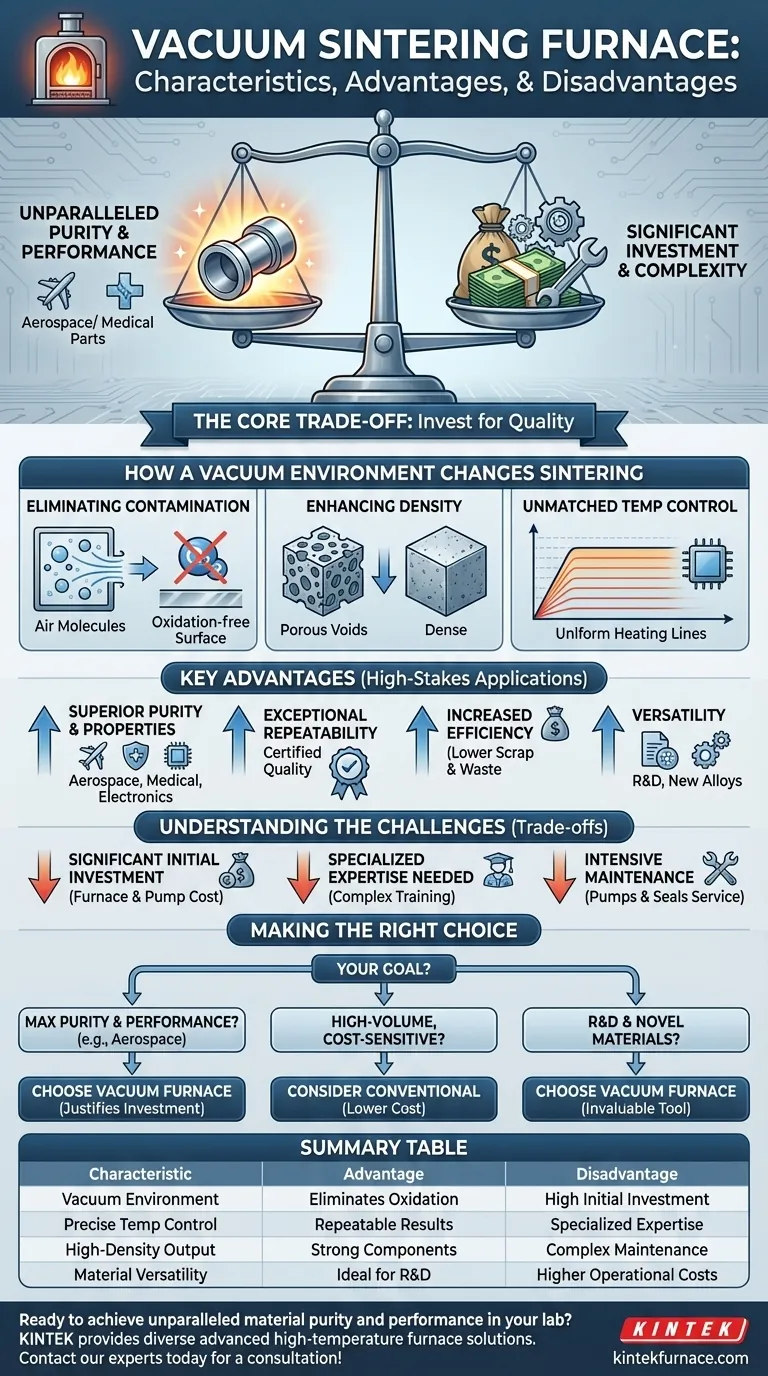

How a Vacuum Environment Changes Sintering

The defining characteristic of this furnace is the removal of air and other gases from the heating chamber. This fundamental difference from atmospheric furnaces creates several distinct advantages during the sintering process.

Eliminating Atmospheric Contamination

At high temperatures, most materials react with gases in the air, especially oxygen. This process, known as oxidation, can degrade material properties and create unwanted surface layers.

A vacuum furnace removes these reactive gases, creating a clean environment. This prevents oxidation, nitridation, and other unwanted chemical reactions, ensuring the final product is chemically pure and stable.

Enhancing Density and Structural Integrity

Trapped gases are a primary cause of porosity, or tiny voids, within a sintered part. These pores can act as stress points, weakening the final component.

By removing the air before heating, a vacuum environment significantly reduces the formation of bubbles and voids. This results in a final product with higher density, greater strength, and superior resistance to wear.

Achieving Unmatched Temperature Control

The vacuum minimizes heat loss through convection, allowing for highly efficient and uniform heating. Modern vacuum furnaces use advanced, computer-driven controllers to manage the process.

This enables extremely precise temperature profiles, with stable and repeatable heating and cooling cycles. This level of control is critical for processing sensitive materials and achieving consistent metallurgical results.

The Key Advantages for High-Stakes Applications

The unique process environment of a vacuum furnace delivers tangible benefits, making it the preferred choice for industries where material performance is non-negotiable.

Superior Material Purity and Properties

The absence of contamination results in cleaner end products with enhanced mechanical, thermal, and electrical characteristics. This is essential for applications in aerospace, medical implants, and advanced electronics where impurity can lead to catastrophic failure.

Exceptional Process Repeatability

Computer-controlled heating, cooling, and gas flow ensures that every production run is identical. This metallurgical repeatability is crucial for quality control and certification in regulated industries.

Increased Energy and Material Efficiency

Because a vacuum is a superb insulator, less energy is wasted heating the surrounding environment. The high-purity output also leads to lower scrap rates and reduced material waste, offsetting some of the higher operational costs.

Versatility Across Materials

Vacuum furnaces are highly adaptable and suitable for a wide range of materials and processes. They are an ideal tool for research and development of new alloys and advanced materials that cannot be processed in a standard atmosphere.

Understanding the Trade-offs and Challenges

While powerful, a vacuum furnace is not the right solution for every application. The benefits come with significant and practical considerations that must be weighed carefully.

Significant Initial Investment

Vacuum sintering furnaces are among the most expensive types of industrial furnaces. The cost includes the furnace itself, the powerful vacuum pumps, and the sophisticated control systems required to operate it.

The Need for Specialized Expertise

Operating and maintaining a high-vacuum system is far more complex than a standard furnace. It requires specialized knowledge of vacuum technology, leak detection, and process control, meaning operators need specific training.

Maintenance and Operational Demands

Vacuum systems have more components that can fail, such as pumps, seals, and sensors. Regular maintenance is more intensive and critical to ensure the system can achieve and hold the required low pressure for a successful sintering cycle.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the required quality of your final product and your operational constraints.

- If your primary focus is maximum material purity and performance (e.g., aerospace, medical): The benefits of eliminating contamination and improving structural integrity justify the investment.

- If your primary focus is high-volume, cost-sensitive production: The high capital cost and operational complexity may be prohibitive, and a conventional atmosphere furnace could be more suitable.

- If your primary focus is research and development: The precise control, versatility, and ability to work with novel materials make a vacuum furnace an invaluable tool.

Ultimately, choosing a vacuum furnace is a strategic decision to prioritize final component quality above all other factors.

Summary Table:

| Characteristic | Advantage | Disadvantage |

|---|---|---|

| Vacuum Environment | Eliminates atmospheric contamination (oxidation) | High initial investment in equipment and pumps |

| Precise Temperature Control | Enables uniform heating and repeatable results | Requires specialized operator expertise and training |

| High-Density Output | Creates strong, wear-resistant components with low porosity | Intensive, complex maintenance for pumps and seals |

| Material Versatility | Ideal for R&D and sensitive materials (aerospace, medical) | Higher operational costs compared to atmosphere furnaces |

Ready to achieve unparalleled material purity and performance in your lab?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let's discuss how a KINTEK vacuum sintering furnace can be tailored to your specific application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity