The primary purpose of performing a 1400°C heat treatment is to structurally reinforce the porous tungsten skeleton through atomic diffusion. This high-temperature step transforms a fragile arrangement of particles into a mechanically stable network by promoting the formation of a tungsten-titanium solid solution, ensuring the material does not collapse during subsequent processing.

Core Takeaway The 1400°C vacuum treatment is a critical strengthening phase that drives the mutual diffusion of tungsten and titanium atoms. This process thickens the "necks" between particles and creates a robust solid solution, providing the necessary toughness to survive the harsh conditions of secondary dealloying.

The Mechanism of Structural Reinforcement

Promoting Atomic Diffusion

At 1400°C, the thermal energy is sufficient to activate the movement of atoms within the metal matrix. This environment promotes the mutual diffusion of tungsten and titanium atoms.

Formation of a Solid Solution

As these atoms diffuse, they do not merely sit side-by-side; they integrate to form a solid solution. This chemical homogenization is fundamental to changing the material properties from a loose aggregate to a unified metallic entity.

Strengthening Particle Connections

The most visible physical change occurs at the contact points between individual particles. The diffusion process causes these contact points, or "neck connections," to become significantly thicker and more rounded. This sintering effect creates a continuous, rigid framework.

Preparing for Downstream Processing

Preventing Structural Collapse

The immediate goal of this heat treatment is to prepare the skeleton for secondary dealloying. This subsequent step (targeting the titanium phase) is aggressive. Without the mechanical stability provided by the 1400°C treatment, the porous skeleton would lack the toughness to maintain its shape and would likely suffer structural collapse.

Optimizing Pore Distribution

Beyond simple strengthening, this thermal treatment actively optimizes pore distribution. By rounding the particle necks and settling the structure, the treatment ensures that the porosity is uniform and stable, which is critical for the material's final application performance.

Understanding the Trade-offs

The Risk of Omission

Skipping or reducing the temperature of this step is not a viable efficiency saving. Without the formation of the solid solution and the thickening of particle necks, the skeleton remains brittle. It will almost certainly fail mechanically when subjected to the stress of removing the titanium phase later.

Distinction from Debinding

It is crucial not to confuse this 1400°C strengthening step with earlier vacuum debinding. Debinding typically occurs below 500°C to slowly decompose organic binders (like PVB) and prevent cracking. The 1400°C step is purely about metallurgical bonding and diffusion, not organic removal.

Ensuring Process Success

To apply this to your manufacturing workflow, consider your specific stability requirements:

- If your primary focus is Structural Integrity: Ensure the dwell time at 1400°C is sufficient to allow complete neck growth and rounding, as this geometry dictates the skeleton's toughness.

- If your primary focus is Process Yield: Prioritize this step to prevent material loss during secondary dealloying, as a well-diffused solid solution is the only defense against skeletal collapse.

The 1400°C treatment is the defining moment where your material transitions from a packed powder to a robust, engineered porous metal.

Summary Table:

| Process Phase | Primary Mechanism | Key Outcome |

|---|---|---|

| Atomic Diffusion | Mutual W-Ti movement | Formation of a robust solid solution |

| Neck Growth | Sintering at contact points | Thicker connections between particles |

| Structural Fixation | Thermal stabilization | Prevention of collapse during secondary dealloying |

| Pore Optimization | Geometry settling | Uniform and stable pore distribution |

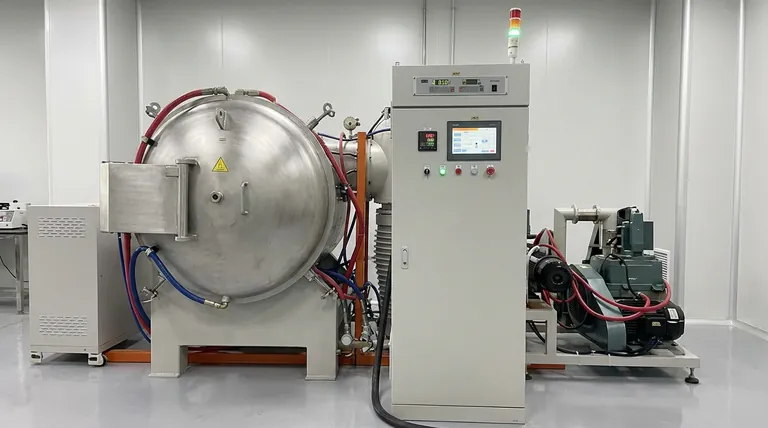

Elevate Your Advanced Material Processing with KINTEK

Precise thermal control is the difference between a robust engineered framework and structural failure. KINTEK provides industry-leading high-temperature vacuum and atmospheric furnaces designed to facilitate critical metallurgical bonding and diffusion processes.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our systems are engineered for peak performance in demanding environments.

- Versatile Solutions: Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, we have the technology to meet your specifications.

- Fully Customizable: We tailor our lab high-temp furnaces to your unique dealloying and sintering requirements.

Ensure your manufacturing success with equipment built for precision. Contact KINTEK today to discuss your custom furnace needs!

References

- Ke Zhu, Jian Zhang. The Integrated Preparation of Porous Tungsten Gradient Materials with a Wide Porosity Range. DOI: 10.3390/met14040427

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?