In vacuum brazing, joint clearance is the single most critical factor in creating a sound, high-strength metallurgical bond. This gap between the mating surfaces must be precisely controlled because it directly governs the capillary action that draws the molten filler metal into the joint. Without the correct clearance, the filler metal will either fail to flow or fail to form a strong, continuous connection.

The success or failure of a brazed joint is fundamentally decided by its clearance. While factors like cleanliness and temperature are crucial, they only serve to support the primary physical principle: capillary action requires a specific, tightly controlled gap to function correctly.

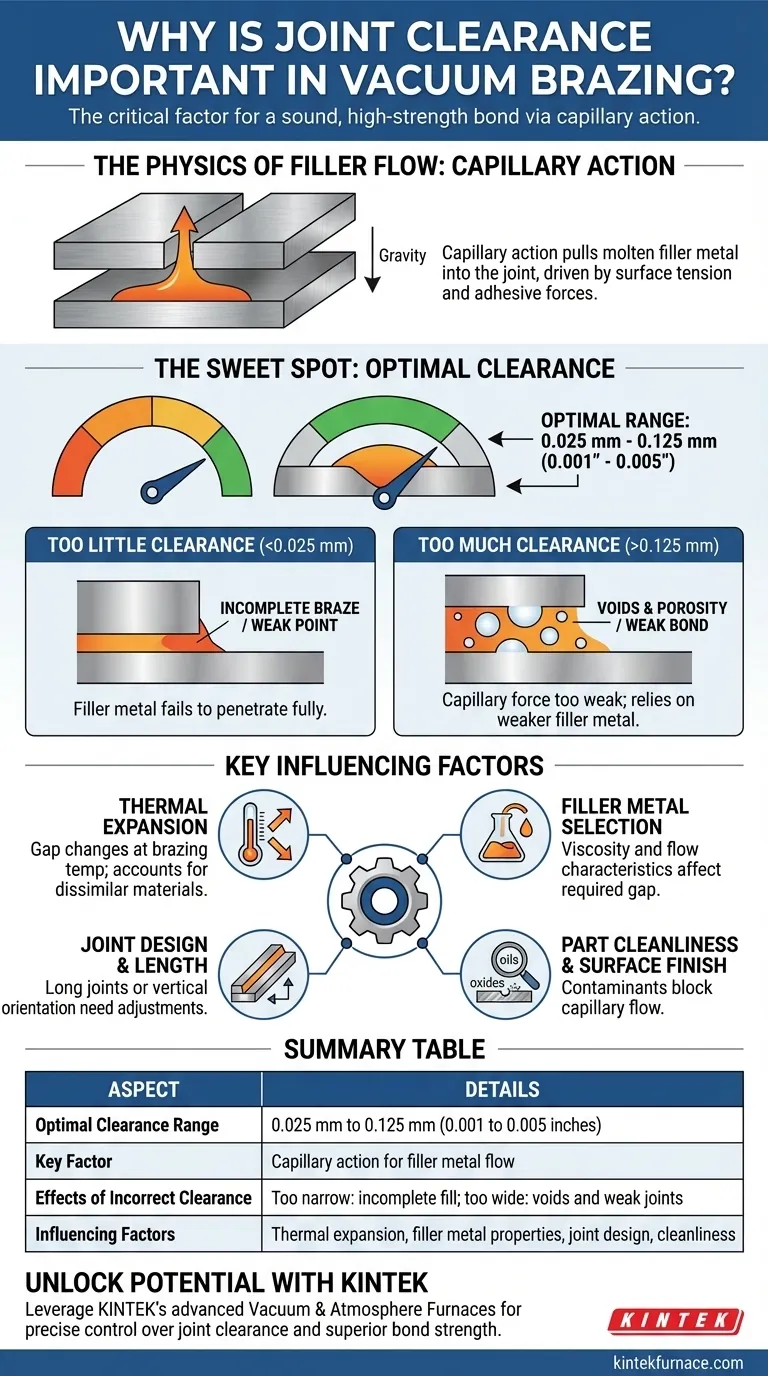

The Physics of Filler Flow

The entire principle of brazing relies on using capillary action to distribute a thin layer of molten filler metal between two closely fitted surfaces.

What is Capillary Action?

Capillary action is the tendency of a liquid to be drawn into a narrow space, even against opposing forces like gravity. This phenomenon is driven by the surface tension of the liquid and the adhesive forces between the liquid and the surfaces of the gap.

In brazing, the molten filler metal is "pulled" into the joint by this force, ensuring it wets the surfaces and fills the entire gap.

The "Sweet Spot" for Clearance

For most common brazing filler metals, the optimal joint clearance is between 0.025 mm and 0.125 mm (approximately 0.001 to 0.005 inches).

This range provides a capillary force strong enough to pull the filler metal through the entire joint length while being wide enough to allow the liquid metal to flow without obstruction.

The Problem with Too Little Clearance

If the joint clearance is too narrow, the molten filler metal may not be able to penetrate the gap fully. This results in an incomplete braze with large, un-bonded areas, creating a significant weak point.

The Problem with Too Much Clearance

If the gap is too wide, the capillary force becomes too weak to draw the filler metal across the entire joint. This leads to voids, porosity, and an incomplete bond.

In this scenario, the joint's strength becomes reliant on the strength of the filler metal itself, which is significantly weaker than a properly brazed joint where the base metals are held by the thin, powerful bond.

Understanding the Key Influencing Factors

Achieving the correct clearance at brazing temperature is more complex than simply machining parts to a specific dimension. Several factors must be considered.

Thermal Expansion

This is a critical consideration. The joint clearance specified on a drawing is the clearance at room temperature. As the assembly is heated to brazing temperature, the different parts will expand.

If you are brazing dissimilar materials with different coefficients of thermal expansion, the gap can either close up or widen significantly at temperature. This must be calculated and accounted for in the initial design.

Filler Metal Selection

Different filler metals have different viscosities and flow characteristics. A more fluid filler metal may perform better with a tighter clearance, while a more sluggish one might require a slightly wider gap to ensure complete flow.

Joint Design and Length

The distance the filler metal must travel matters. A very long joint may require a clearance on the wider side of the optimal range to ensure the filler can penetrate all the way through before solidifying. The orientation of the joint (horizontal vs. vertical) also influences the effect of gravity on filler flow.

Part Cleanliness and Surface Finish

While not a direct aspect of clearance, the condition of the base metal surfaces is paramount. Any oxides, oils, or contaminants will disrupt wetting and inhibit capillary flow, effectively blocking the filler metal even if the mechanical clearance is perfect.

How to Apply This to Your Project

Choosing the optimal clearance requires balancing these factors against your primary goal for the component.

- If your primary focus is maximum mechanical strength: Aim for the tighter end of the optimal range (e.g., 0.025 to 0.05 mm), as this typically creates the strongest joint.

- If your primary focus is ensuring complete joint fill on large or complex parts: Consider a clearance in the middle to upper end of the range (e.g., 0.05 to 0.125 mm) to facilitate filler metal flow over longer distances.

- If your primary focus is brazing dissimilar materials: Your first step must be to calculate the joint clearance at the brazing temperature to ensure the gap remains within the optimal range during the thermal cycle.

Properly controlling joint clearance is not just a best practice; it is the fundamental principle that defines a successful brazed joint.

Summary Table:

| Aspect | Details |

|---|---|

| Optimal Clearance Range | 0.025 mm to 0.125 mm (0.001 to 0.005 inches) |

| Key Factor | Capillary action for filler metal flow |

| Effects of Incorrect Clearance | Too narrow: incomplete fill; too wide: voids and weak joints |

| Influencing Factors | Thermal expansion, filler metal properties, joint design, cleanliness |

Unlock the full potential of your vacuum brazing processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, tailored to your unique needs. Our deep customization capabilities ensure precise control over joint clearance and other critical parameters for superior bond strength and reliability. Don't let improper clearance compromise your results—contact us today to discuss how our expertise can enhance your laboratory's efficiency and success!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement