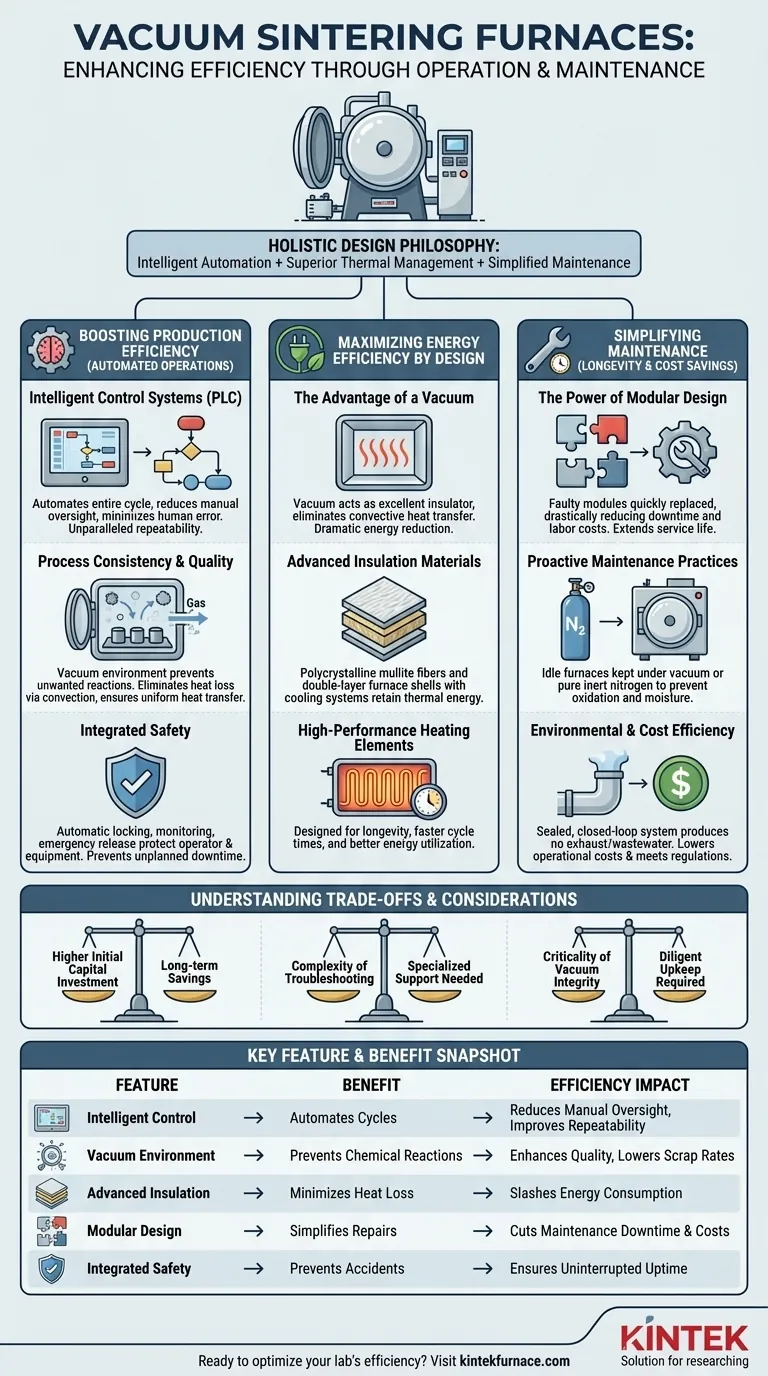

Ultimately, the efficiency of a vacuum sintering furnace stems from a holistic design philosophy that combines intelligent automation, superior thermal management, and simplified maintenance. These features work in concert to reduce manual intervention, slash energy consumption, and minimize downtime, directly impacting production throughput, operational costs, and equipment longevity.

The key takeaway is not a single feature, but the systemic integration of automation, advanced materials, and modular design. This transforms the furnace from a simple heating tool into a highly efficient production asset that lowers costs, improves product quality, and maximizes operational uptime.

Boosting Production Efficiency Through Automated Operations

Operational efficiency is about maximizing output and ensuring consistent quality with minimal manual effort. Modern vacuum furnaces achieve this through sophisticated control and inherent process advantages.

The Role of Intelligent Control Systems

At the core of a modern vacuum furnace is an intelligent control system, often a Programmable Logic Controller (PLC). This system automates the entire sintering cycle, from pumping down the vacuum to precise temperature ramps and cooling sequences.

This automation significantly reduces the need for constant manual oversight, freeing up operators for other tasks and minimizing the risk of human error. The result is higher production efficiency and unparalleled process repeatability.

Ensuring Process Consistency and Quality

The vacuum environment itself is a critical feature for efficiency. By removing atmospheric gases, it prevents unwanted chemical reactions with the materials being sintered, leading to purer, higher-quality final products.

This controlled environment also eliminates heat loss through gas convection, allowing for more uniform and effective heat transfer directly to the part. This ensures consistent metallurgical properties batch after batch, reducing scrap rates and costly rework.

Integrated Safety for Uninterrupted Uptime

Advanced safety features are integrated directly into the PLC. Functions like automatic door locking, over-temperature and over-pressure monitoring, and emergency release valves protect both the operator and the equipment.

By preventing accidents and equipment damage, these systems safeguard against unplanned and expensive downtime, which is a major source of inefficiency.

Maximizing Energy Efficiency by Design

Energy is a primary operational cost. Vacuum furnace design directly targets the reduction of energy consumption through several key principles.

The Advantage of a Vacuum Environment

A vacuum is an excellent insulator. With virtually no gas molecules inside the chamber, heat transfer via convection is almost entirely eliminated. This means the vast majority of energy is used to heat the product, not the surrounding space, dramatically reducing overall energy consumption compared to conventional furnaces.

Advanced Insulation Materials

To combat heat loss through conduction and radiation, these furnaces use high-quality insulation like polycrystalline mullite fibers. These materials enable rapid heating cycles while retaining thermal energy effectively.

This is often complemented by double-layer furnace shells with an air-cooling or water-cooling system, which keeps the exterior cool and further prevents thermal energy from escaping.

High-Performance Heating Elements

Modern furnaces employ advanced heating elements and technology designed for longevity and performance. Their design allows them to operate efficiently without the typical wattage limitations, contributing to faster cycle times and better energy utilization.

Simplifying Maintenance for Longevity and Cost Savings

Efficiency is not just about a single production cycle; it's about the entire life cycle of the equipment. Features that simplify maintenance are crucial for long-term cost savings.

The Power of Modular Design

Many vacuum furnaces are built with a modular design, particularly for components like heating elements. This approach simplifies troubleshooting and repair significantly.

Instead of a complex, time-consuming repair, a faulty module can be quickly replaced, drastically reducing maintenance downtime and labor costs. This design philosophy extends the furnace's overall service life.

Proactive Maintenance Practices

The operational design encourages best practices. To maintain peak performance and prevent moisture absorption or oxidation of internal components, an idle furnace should be kept under a slight vacuum or filled with pure, inert nitrogen. This simple procedure preserves the integrity of the system and prevents future problems.

Environmental and Cost Efficiency

The sealed, closed-loop nature of a vacuum furnace offers another layer of efficiency. It produces no exhaust gases or wastewater, eliminating the need for expensive secondary treatment systems. This not only lowers operational costs but also helps meet stringent environmental regulations with ease.

Understanding the Trade-offs and Considerations

While highly efficient, this technology is not without its specific considerations. A balanced understanding is crucial for a sound investment.

Higher Initial Capital Investment

The sophisticated control systems, vacuum pumps, and advanced materials used in vacuum sintering furnaces result in a higher upfront cost compared to simpler atmospheric furnaces. This initial investment must be weighed against the long-term savings in energy, labor, and improved product quality.

Complexity of Troubleshooting

While modularity simplifies the replacement of parts, diagnosing issues within the integrated control and vacuum systems can be complex. It often requires specialized knowledge or technician support, particularly for elusive vacuum leaks or PLC programming errors.

The Criticality of Vacuum Integrity

The efficiency gains are entirely dependent on maintaining a high-quality vacuum. Even a minor leak can compromise a production batch and is a primary maintenance focus. Achieving and holding a deep vacuum requires diligent upkeep of all seals, flanges, and connections.

Making the Right Choice for Your Goal

The "best" features depend entirely on your primary production objective.

- If your primary focus is high throughput: Prioritize a furnace with a powerful PLC for full automation and advanced heating elements and insulation for rapid heating and cooling cycles.

- If your primary focus is minimizing operational cost: Emphasize features for energy efficiency, such as multi-layer insulation and a high-quality vacuum system, along with a modular design to reduce long-term maintenance expenses.

- If your primary focus is process-critical quality: Scrutinize the precision of the temperature and pressure control systems and ensure the vacuum integrity is sufficient to prevent any atmospheric contamination.

By understanding how these features function as a system, you can select or operate a furnace that serves as a strategic asset for your production goals.

Summary Table:

| Feature | Key Benefit | Impact on Efficiency |

|---|---|---|

| Intelligent Control Systems | Automates sintering cycles | Reduces manual oversight, improves repeatability |

| Vacuum Environment | Prevents chemical reactions | Enhances product quality, lowers scrap rates |

| Advanced Insulation | Minimizes heat loss | Slashes energy consumption |

| Modular Design | Simplifies repairs | Cuts maintenance downtime and costs |

| Integrated Safety | Prevents accidents | Ensures uninterrupted uptime |

Ready to optimize your lab's efficiency with advanced vacuum sintering furnaces? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is enhanced by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our furnaces can boost your productivity, reduce costs, and ensure long-term reliability!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why is a high-vacuum environment necessary in copper slag impoverishment? Maximize Your Matte Separation Efficiency

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion