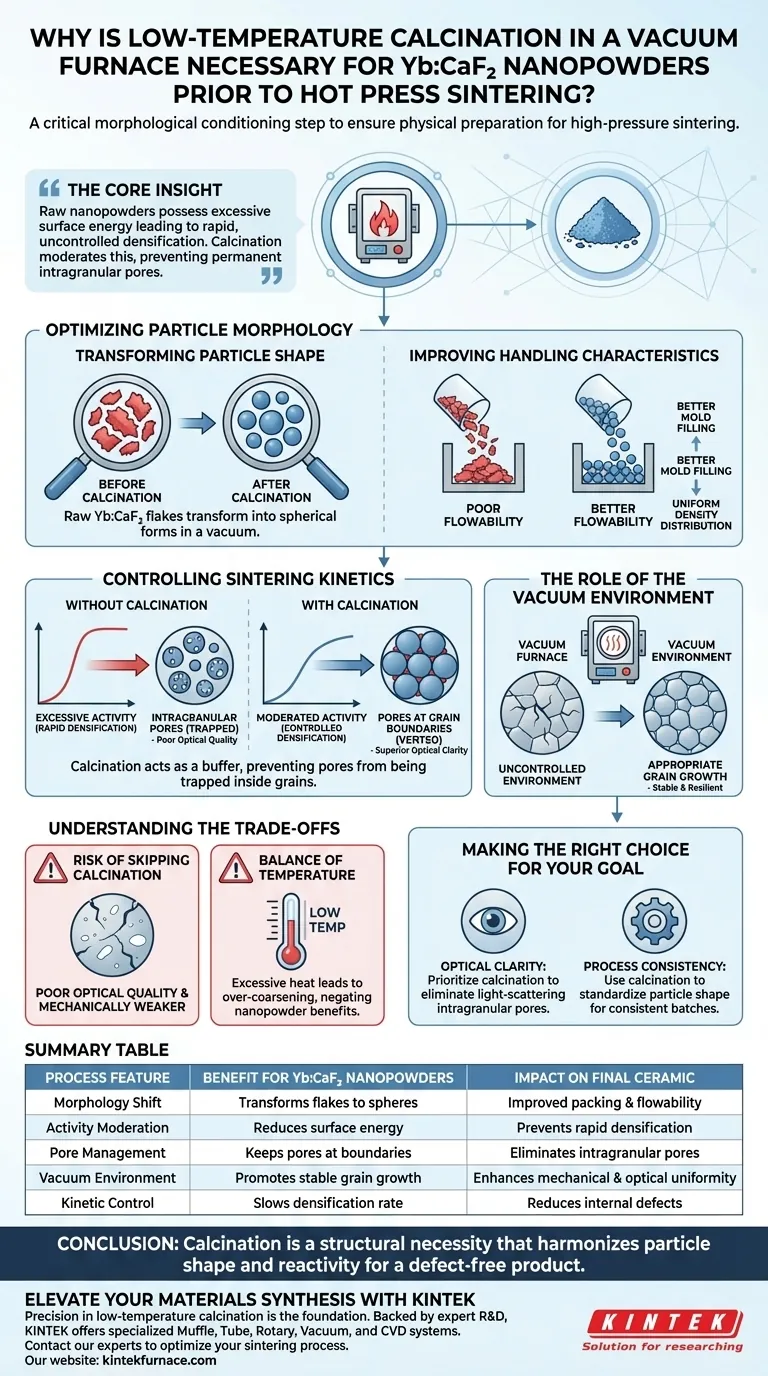

Low-temperature calcination serves as a critical morphological conditioning step for Yb:CaF2 nanopowders. It primarily functions to transform the particle shape from irregular, flake-like structures into uniform spheres, ensuring the material is physically prepared for the high pressures of sintering.

The Core Insight Raw nanopowders often possess excessive surface energy that leads to rapid, uncontrolled densification. Calcination moderates this activity, preventing the formation of permanent defects known as intragranular pores.

Optimizing Particle Morphology

Transforming Particle Shape

Raw Yb:CaF2 nanopowders often exist as irregular, flake-like particles. Low-temperature calcination in a vacuum environment induces a physical transformation, reshaping these particles into spherical forms.

Improving Handling Characteristics

This morphological shift significantly improves the flowability and dispersibility of the powder. Spherical particles pack more efficiently and move more freely than flakes, which facilitates better mold filling and uniform density distribution prior to the main sintering phase.

Controlling Sintering Kinetics

Reducing Excessive Sintering Activity

Nanopowders naturally have high surface activity, which can trigger densification too early or too quickly. Calcination acts as a buffer, reducing this excessive sintering activity to a manageable level.

Preventing Intragranular Pores

If densification occurs too rapidly, grain boundaries sweep past pores before they can be eliminated, trapping them inside the grains. These intragranular pores are notoriously difficult to remove later. By moderating the densification rate, calcination ensures pores remain at the grain boundaries where they can be effectively vented.

The Role of the Vacuum Environment

Promoting Appropriate Grain Growth

The vacuum furnace environment does not just reshape particles; it promotes appropriate grain growth. This controlled growth ensures the grains are stable enough to withstand sintering without coarsening to the point where material properties degrade.

Understanding the Trade-offs

The Risk of Skipping Calcination

Attempting to hot press raw, flake-like nanopowders typically results in a ceramic with poor optical quality. The rapid densification traps microscopic air pockets inside the crystal structure, rendering the final material less transparent and mechanically weaker.

The Balance of Temperature

While calcination is necessary, it must be kept at a "low temperature" relative to the final sintering point. Excessive heat during this pre-processing stage could lead to over-coarsening of grains, negating the benefits of using nanopowders in the first place.

Making the Right Choice for Your Goal

To maximize the quality of your Yb:CaF2 ceramics, align your process with these objectives:

- If your primary focus is Optical Clarity: Prioritize calcination to eliminate intragranular pores, which are the main scatterers of light in sintered ceramics.

- If your primary focus is Process Consistency: Use calcination to standardize particle shape, ensuring consistent flow and packing density from batch to batch.

Conclusion: Calcination is not merely a cleaning step; it is a structural necessity that harmonizes particle shape and reactivity to ensure a defect-free final product.

Summary Table:

| Process Feature | Benefit for Yb:CaF2 Nanopowders | Impact on Final Ceramic |

|---|---|---|

| Morphology Shift | Transforms flake-like particles into uniform spheres | Improved packing density & flowability |

| Activity Moderation | Reduces excessive surface energy of nanopowders | Prevents rapid, uncontrolled densification |

| Pore Management | Keeps pores at grain boundaries for venting | Eliminates light-scattering intragranular pores |

| Vacuum Environment | Promotes stable and appropriate grain growth | Enhances mechanical & optical uniformity |

| Kinetic Control | Slows densification to a manageable rate | Reduces internal defects and air pockets |

Elevate Your Materials Synthesis with KINTEK

Precision in low-temperature calcination is the foundation of high-performance Yb:CaF2 ceramics. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of nanopowder processing.

Whether you need precise atmosphere control or customizable heating profiles for your unique lab requirements, our high-temperature furnaces provide the stability needed to prevent intragranular pores and ensure superior optical quality.

Ready to optimize your sintering process? Contact our experts today to find the perfect customizable solution for your laboratory.

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a vacuum drying oven essential during the precursor treatment of Pt/Ce(M) catalysts? Ensure High Metal Dispersion

- What are graphite retorts used for in vacuum furnaces? A Guide to High-Temperature Processing

- What are the working environment requirements for a vacuum furnace? Ensure Safety and Purity for Your Lab

- What is a major limitation of hot wall vacuum furnaces? Temperature Capability and Design Trade-offs

- What factors should be considered when choosing between argon and nitrogen for vacuum furnace applications? Optimize Your Heat Treatment Process

- What role does a vacuum annealing furnace play in evaluating Ag2S1-xTex phase stability? Map Material Limits Precisely

- What are the advantages of using heat treatment and vacuum furnaces? Achieve Superior Material Quality and Control

- Why is a vacuum environment essential when using a Spark Plasma Sintering (SPS) furnace for Ti64-Si3N4-ZrO2? Achieve Optimal Density & Purity