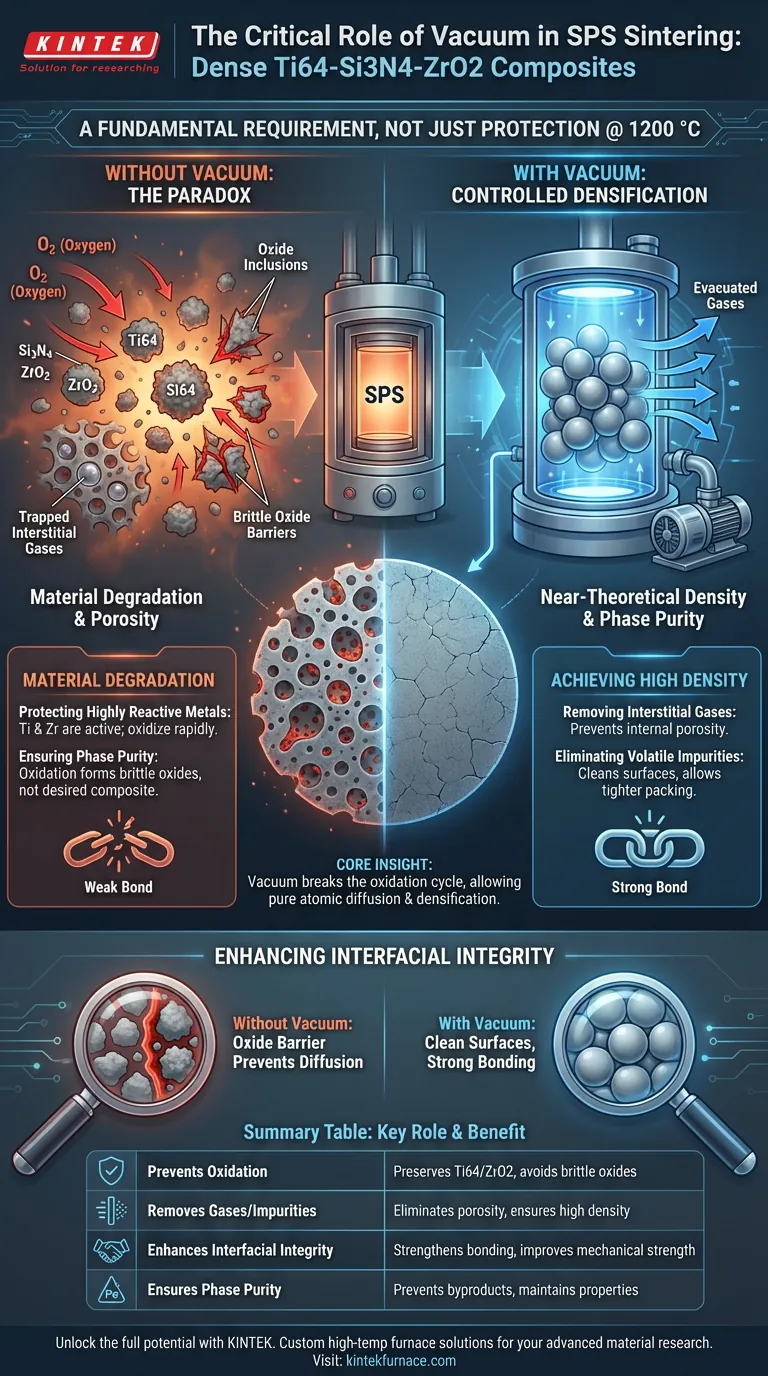

The vacuum environment in a Spark Plasma Sintering (SPS) furnace is not merely a protective measure; it is a fundamental requirement for processing reactive composites like Ti64-Si3N4-ZrO2.

At the requisite sintering temperature of 1200 °C, the vacuum performs two critical functions: it actively removes interstitial gases and volatile impurities that cause porosity, and it prevents the oxidation of the highly reactive titanium alloy. This dual action is the only way to ensure the material achieves near-theoretical density and maintains the necessary phase purity.

Core Insight Processing Titanium and Zirconium-based composites without a vacuum creates a paradox: the heat required to sinter the material is also sufficient to destroy it through oxidation. A vacuum environment breaks this cycle, stripping away gaseous barriers and chemical contaminants to allow for pure, uninhibited atomic diffusion and densification.

Preventing Material Degradation

The presence of oxygen during the high-temperature sintering of Ti64-Si3N4-ZrO2 leads to immediate and detrimental chemical changes.

Protecting Highly Reactive Metals

Titanium (in Ti64) and Zirconium (in ZrO2) are active metals with a strong affinity for oxygen. At 1200 °C, even trace amounts of oxygen will cause these elements to oxidize rapidly. The vacuum environment effectively isolates the powder mixture, preserving the metallic and ceramic phases in their intended state.

Ensuring Phase Purity

If oxidation occurs, the material forms brittle oxide inclusions rather than the desired composite structure. Maintaining a vacuum ensures phase purity, meaning the final product consists only of the intended Ti64, Si3N4, and ZrO2 components, without unwanted reaction byproducts that degrade performance.

Mechanisms for Achieving High Density

To create a dense composite, solid particles must fuse together completely. Gases trapped within the powder bed act as physical barriers to this process.

Removing Interstitial Gases

Raw powders naturally contain gaps filled with air (interstitial gases). The vacuum system extracts these gases before and during the heating process. This removal is essential to prevent gas entrapment, which would otherwise result in internal porosity and a weaker final structure.

Eliminating Volatile Impurities

Raw materials often contain surface contaminants or volatile impurities. Under vacuum conditions, these impurities vaporize and are evacuated from the chamber. This purification step cleans the particle surfaces, allowing for tighter packing and higher final density.

Enhancing Interfacial Integrity

The mechanical strength of a composite relies on how well the different materials (metal and ceramic) bond at their interface.

Removing Oxide Barriers

Oxide films on particle surfaces act as a barrier to atomic diffusion. By preventing these films from forming or growing, the vacuum allows atoms to move freely between the Ti64 matrix and the ceramic reinforcements (Si3N4 and ZrO2).

Strengthening the Bond

Clean surfaces result in high-quality interfacial bonding. When the "sintering neck" forms between particles without an oxide layer interfering, the bond is stronger and more uniform. This direct contact is critical for transferring stress effectively throughout the composite material.

Common Pitfalls to Avoid

While vacuum is essential, it must be balanced with other processing parameters to ensure success.

Misinterpreting Vacuum Levels

A "standard" vacuum may not be enough for highly active metals like Titanium or Zirconium. You must ensure the vacuum level is sufficient to lower the partial pressure of oxygen below the threshold required for oxidation at 1200 °C.

Ignoring Vapor Pressure

While the goal is to remove impurities, extremely high vacuums at high temperatures can theoretically cause the sublimation of alloying elements if their vapor pressures are high. However, for Ti64-Si3N4-ZrO2 at 1200 °C, the primary risk remains oxidation and gas entrapment, making the vacuum indispensable.

Making the Right Choice for Your Goal

The role of the vacuum affects different aspects of the final material. Tailor your focus based on your specific performance requirements.

- If your primary focus is Mechanical Strength: Prioritize the vacuum's ability to prevent oxide formation, as brittle oxides at the interface are the primary cause of premature fracture.

- If your primary focus is Maximum Density: Focus on the vacuum's ability to evacuate interstitial gases during the initial heating stages to prevent pore formation.

A vacuum environment transforms the sintering process from a fight against contamination into a controlled environment for precise microstructural engineering.

Summary Table:

| Key Role of Vacuum | Benefit for Ti64-Si3N4-ZrO2 Composites |

|---|---|

| Prevents Oxidation of Reactive Metals | Preserves Ti64/ZrO2 phases, avoids brittle oxides |

| Removes Interstitial Gases & Volatile Impurities | Eliminates porosity, ensures high density |

| Enhances Interfacial Integrity | Strengthens bonding, improves mechanical strength |

| Ensures Phase Purity | Prevents unwanted reaction byproducts, maintains material properties |

Unlock the full potential of your advanced material research and production. If your applications demand the highest standards for density, purity, and mechanical strength in composites like Ti64-Si3N4-ZrO2, KINTEK has the expertise and equipment you need. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique needs. Don't compromise on your material's integrity – contact KINTEK's specialists today to discuss your specific SPS or high-temperature furnace requirements and achieve unparalleled results.

Visual Guide

References

- Anthony O. Ogunmefun, Kibambe Ngeleshi. Densification, microstructure, and nanomechanical evaluation of pulsed electric sintered zirconia-silicon nitride reinforced Ti-6Al-4 V alloy. DOI: 10.1007/s00170-023-12873-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the advantages of using a vacuum drying oven for Co-Fe-ZIF particles? Preserve Structural Integrity.

- What are the applications of vacuum brazing furnaces? Achieve Strong, Clean Joints for Aerospace and More

- What is the technical purpose of a vacuum distillation system in VMPPS synthesis? Enhance Polymer Weight and Purity

- What other applications do vacuum furnaces have? Unlock Advanced Material Processing Across Industries

- What is the importance of a vacuum degassing system? Unlock Accurate Activated Carbon Surface Analysis

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- What types of heat treatment processes use vacuum furnaces? Achieve Purity and Precision in Material Processing

- What benefits does vacuum heat treatment provide over traditional methods? Achieve Superior Material Quality and Control