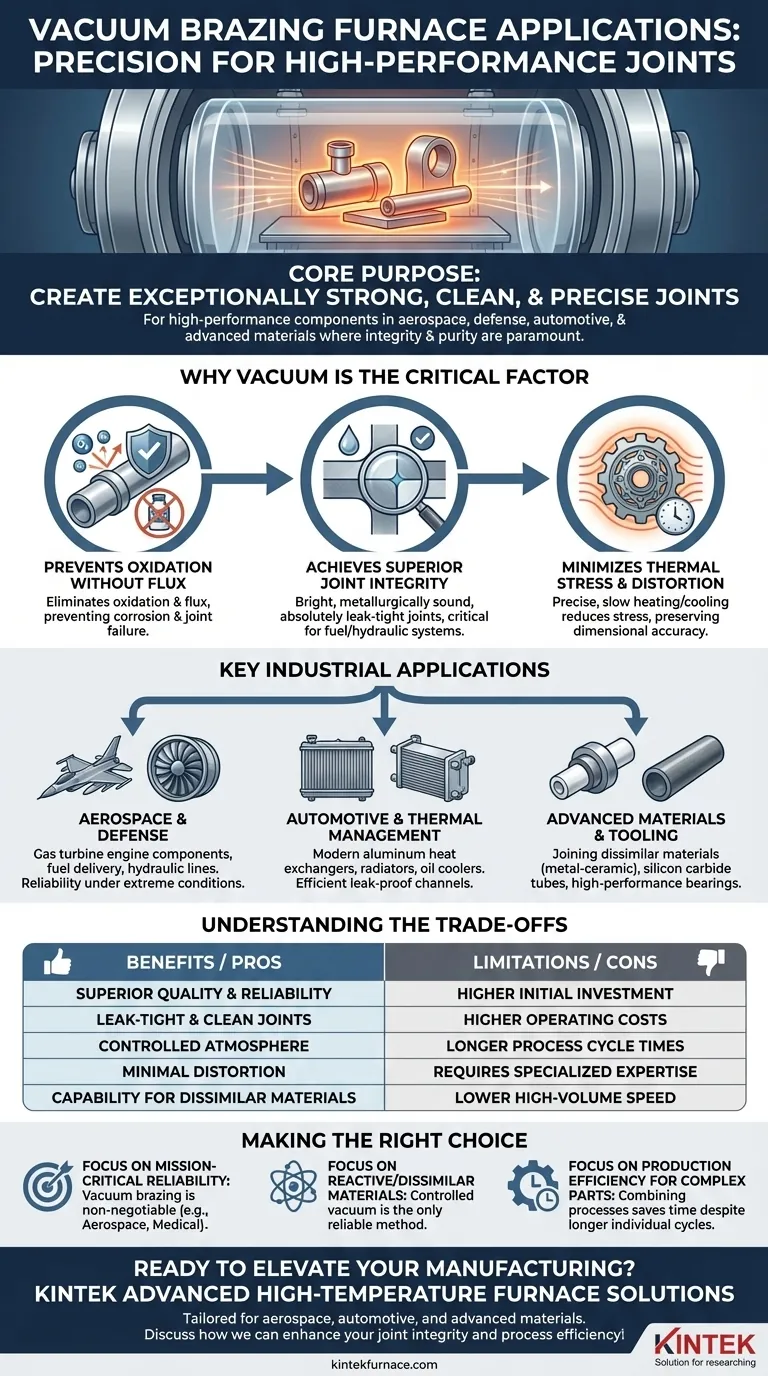

At its core, a vacuum brazing furnace is used to create exceptionally strong, clean, and precise joints in materials that are otherwise difficult or impossible to join with conventional methods. This technology is not for everyday applications; it is a specialized process reserved for high-performance components. Its primary use is in manufacturing for the aerospace, defense, automotive, and advanced materials industries where joint integrity and material purity are paramount.

The true value of a vacuum furnace is not just joining parts, but the ability to do so in a perfectly controlled, contamination-free environment. This prevents oxidation and minimizes thermal stress, making it essential for high-stakes components where failure is not an option.

Why Vacuum is the Critical Factor

The decision to use a vacuum furnace is driven by the need to solve specific material science and engineering challenges that other methods cannot address. The vacuum itself is the active ingredient that enables these unique capabilities.

Preventing Oxidation Without Flux

Many high-performance alloys, such as titanium, aluminum, and stainless steel, are highly reactive with oxygen at brazing temperatures. This reaction creates oxides on the surface that prevent the braze alloy from properly wetting and bonding to the parent material.

A vacuum furnace removes the atmosphere, eliminating the possibility of oxidation. This also removes the need for chemical flux, which avoids the risk of flux entrapment—a common cause of corrosion and joint failure—and eliminates the need for intensive post-braze cleaning.

Achieving Superior Joint Integrity

The clean, fluxless environment results in joints that are bright, metallurgically sound, and exceptionally strong.

Because the process is so clean, it is the preferred method for manufacturing components that must be absolutely leak-tight. This is critical for aerospace fuel and hydraulic system components where even a microscopic flaw could be catastrophic.

Minimizing Thermal Stress and Distortion

A vacuum furnace allows for precise, programmable control over heating and cooling rates. Slow, uniform heating and cooling cycles drastically reduce the thermal stress induced in the parts.

This is vital for maintaining the dimensional accuracy of complex, high-precision components like gas turbine engine parts. By minimizing distortion, the process preserves the engineered metallurgy and structural integrity of the base materials.

Key Industrial Applications

The unique benefits of the vacuum environment make these furnaces indispensable in several key sectors.

Aerospace and Defense

This is the largest and most demanding user of vacuum brazing. The technology is used for manufacturing gas turbine engine components, fuel delivery systems, and hydraulic lines. The process guarantees the reliability and performance required to withstand extreme temperatures, pressures, and vibrations.

Automotive and Thermal Management

Vacuum brazing is essential for producing modern aluminum heat exchangers, such as radiators, oil coolers, and evaporators. The process allows for the joining of thin, complex aluminum assemblies, creating clean, leak-proof channels that are critical for efficient thermal performance.

Advanced Materials and Tooling

The technology extends to materials beyond metals. It is used to join dissimilar materials, such as metals to ceramics, for specialized applications. One example is the manufacturing of silicon carbide tubes and rings used in high-performance bearings, where extreme hardness and heat resistance are required.

Understanding the Trade-offs

While powerful, vacuum furnace technology is not a universal solution. Understanding its limitations is key to making an informed decision.

Initial Investment and Operating Costs

Vacuum furnaces represent a significant capital investment. They are complex machines that require specialized infrastructure and maintenance, leading to higher operating costs compared to simpler methods like torch brazing or atmospheric furnaces.

Process Cycle Times

The very features that ensure quality—slow heating, vacuum pump-down, and controlled cooling—also result in longer cycle times. This can make it less suitable for high-volume production of low-cost, non-critical parts where speed is the primary driver.

Required Expertise

Operating a vacuum furnace effectively requires skilled technicians and engineers. Developing the correct brazing and heat treatment "recipes" for different materials and geometries is a complex task that demands a deep understanding of metallurgy and thermodynamics.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your project's specific requirements for quality, performance, and cost.

- If your primary focus is mission-critical reliability: Vacuum brazing is non-negotiable for components in aerospace or medical devices where joint failure would have severe consequences.

- If your primary focus is joining reactive or dissimilar materials: The controlled vacuum environment is the only reliable way to achieve strong, clean joints with materials like titanium, aluminum, or metal-ceramic assemblies.

- If your primary focus is production efficiency for complex parts: The ability to combine brazing, hardening, and aging into a single furnace cycle can offer significant time and cost savings despite the longer individual cycle time.

Ultimately, adopting vacuum furnace technology is a strategic decision to prioritize quality, repeatability, and material integrity above all else.

Summary Table:

| Application Area | Key Benefits | Common Components |

|---|---|---|

| Aerospace and Defense | Leak-tight joints, high reliability under extreme conditions | Gas turbine engines, fuel systems, hydraulic lines |

| Automotive and Thermal Management | Efficient thermal performance, leak-proof channels | Aluminum heat exchangers, radiators, oil coolers |

| Advanced Materials and Tooling | Joining dissimilar materials, high hardness and heat resistance | Silicon carbide tubes, metal-ceramic assemblies |

Ready to elevate your manufacturing with precision vacuum brazing solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, automotive, and advanced materials. Our product line, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how we can enhance your joint integrity and process efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion