The single greatest limitation of a hot wall vacuum furnace is its maximum operating temperature. Because the entire vessel (the retort) that contains the vacuum is heated externally, its material strength degrades under the combined stress of heat and vacuum pressure. This fundamental design constraint typically limits hot wall furnaces to a maximum temperature of around 1100°C (2000°F).

A hot wall furnace trades high-temperature capability for a simpler, more cost-effective design. Understanding this core trade-off is essential when comparing it to its alternative, the cold wall furnace.

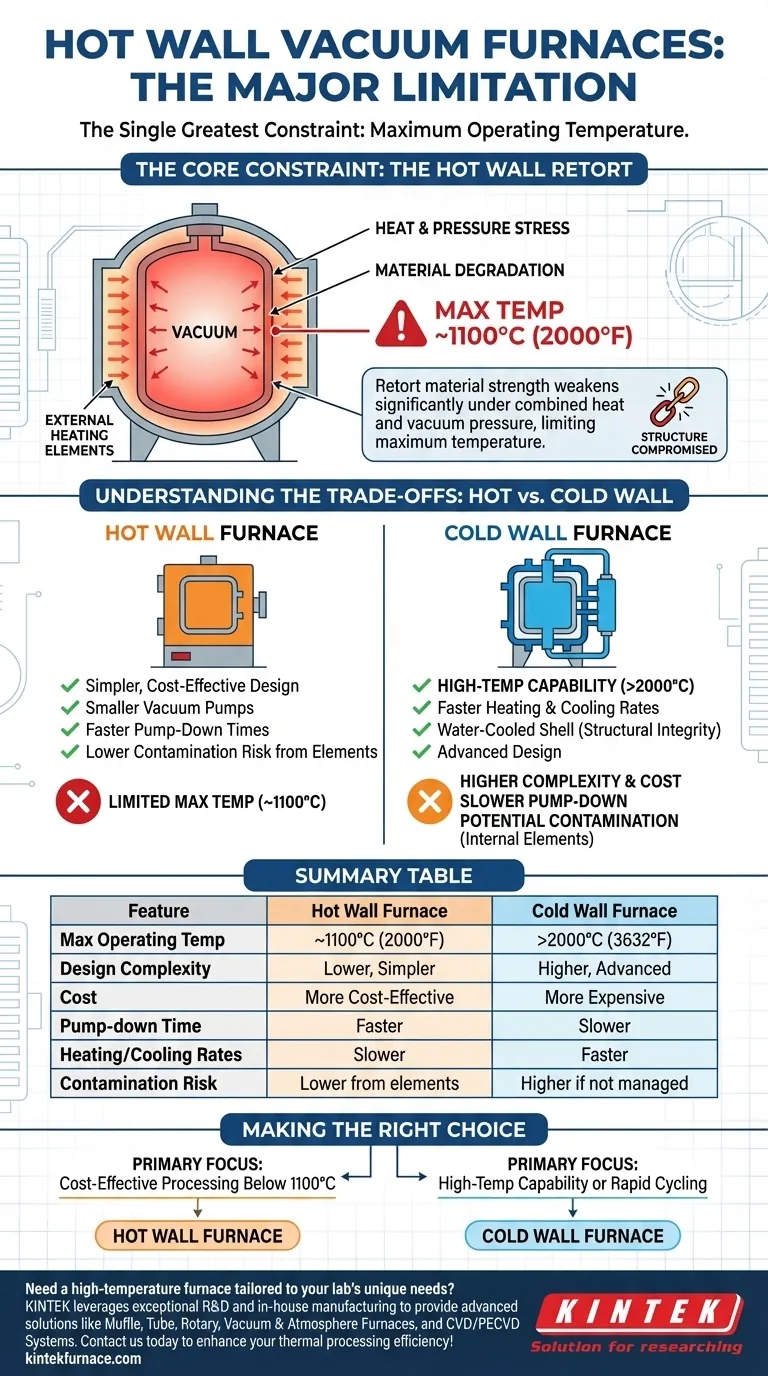

The Core Constraint: The Hot Wall Retort

The defining feature of a hot wall furnace is that the heating elements are located outside the vacuum vessel. This has direct consequences for its performance and physical limits.

Why Temperature is Limited

In a hot wall design, the metal retort must withstand atmospheric pressure on the outside while maintaining a vacuum on the inside, all while being heated to the process temperature.

As the retort's temperature increases, the metal loses its structural integrity and becomes susceptible to creep, distortion, and fatigue. To ensure safety and operational longevity, its temperature must be kept below the point where the material weakens significantly, which for typical alloys is about 1100°C (2000°F).

How This Differs from a Cold Wall Design

A cold wall vacuum furnace solves this problem by reversing the design. The outer vacuum vessel is water-cooled and remains near room temperature, so its structural strength is never compromised.

The heating elements and insulation are placed inside this cool chamber. This architecture allows cold wall furnaces to reach much higher temperatures, often exceeding 2000°C (3632°F), because the only components exposed to extreme heat are specialized internal elements, not the primary pressure vessel itself.

Understanding the Trade-offs

The temperature ceiling is a major limitation, but it doesn't make the hot wall furnace an inferior choice. It simply makes it a specialized tool with a distinct set of advantages and disadvantages.

The Advantage of Simplicity and Cost

Hot wall furnaces are generally less complex and less expensive to manufacture than their cold wall counterparts.

Furthermore, the vacuum is only drawn on the small internal volume of the retort. This means smaller vacuum pumps can be used, leading to faster pump-down times and lower operational costs.

The Performance Edge of a Cold Wall

For applications requiring temperatures above 1100°C, a cold wall furnace is the only viable option.

They also typically offer faster heating and cooling rates. The water-cooled shell acts as an efficient heat sink, allowing for more rapid temperature changes, which can be critical for certain metallurgical processes.

Maintenance and Contamination

In a hot wall furnace, the heating elements are separate from the process environment, which can simplify maintenance and reduce the risk of contamination from the elements themselves.

In a cold wall design, the internal heaters and insulation can sometimes become sources of contamination if not properly managed, adding a layer of complexity to its operation.

Making the Right Choice for Your Process

Choosing between a hot and cold wall furnace is a direct function of your specific process requirements.

- If your primary focus is cost-effective processing below 1100°C (2000°F): A hot wall furnace is often the more efficient, reliable, and economical choice.

- If your primary focus is high-temperature capability or rapid cycling: A cold wall furnace is the necessary and superior technology for your application.

Understanding this fundamental design difference is the key to selecting the right tool for your specific thermal processing needs.

Summary Table:

| Feature | Hot Wall Furnace | Cold Wall Furnace |

|---|---|---|

| Max Operating Temperature | ~1100°C (2000°F) | >2000°C (3632°F) |

| Design Complexity | Lower, simpler | Higher, advanced |

| Cost | More cost-effective | More expensive |

| Pump-down Time | Faster | Slower |

| Heating/Cooling Rates | Slower | Faster |

| Contamination Risk | Lower from elements | Higher if not managed |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise alignment with your experimental requirements. Contact us today to enhance your thermal processing efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today