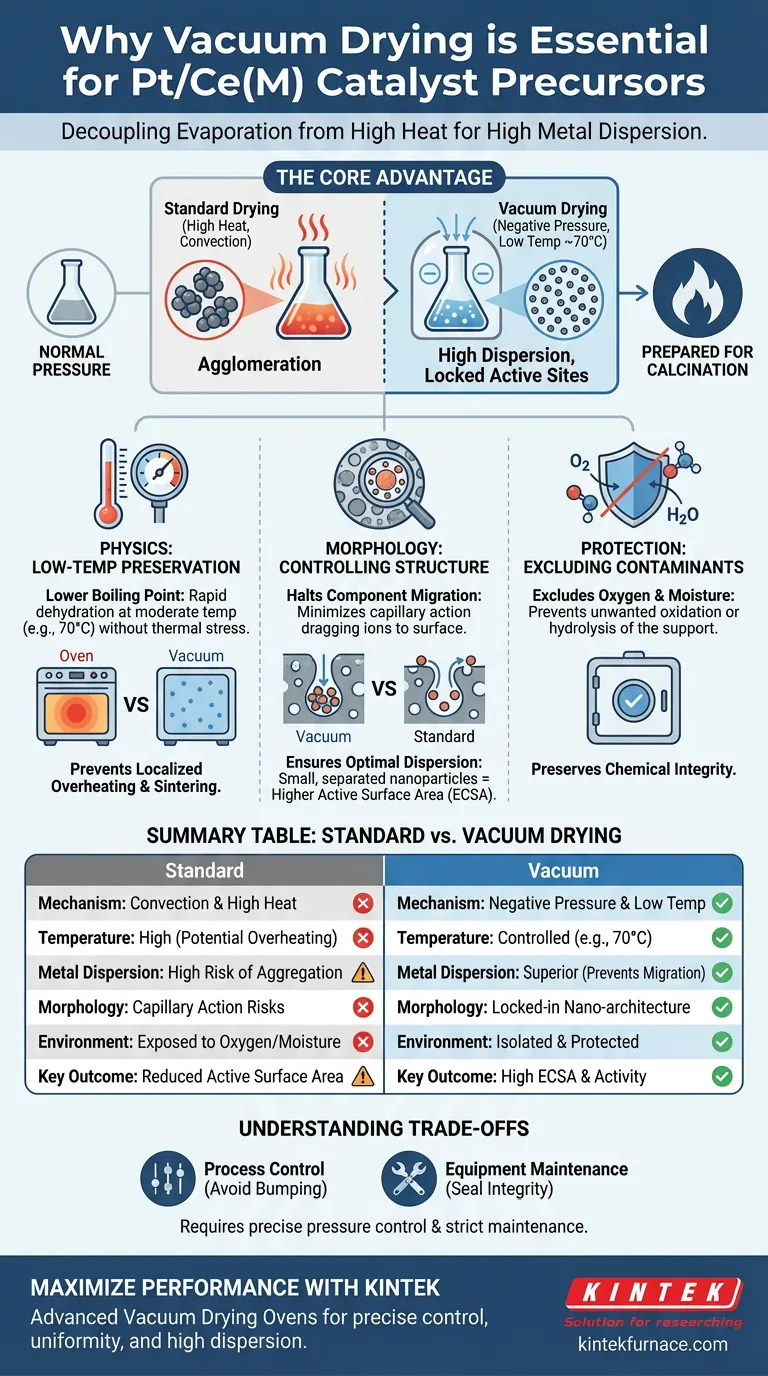

The primary function of a vacuum drying oven in Pt/Ce(M) precursor treatment is to maintain high metal dispersion by decoupling evaporation from high heat. By lowering the boiling point of solvents, the oven allows for rapid dehydration at a moderate temperature of 70°C. This process specifically prevents the migration and pre-aggregation of active metal components that typically result from the localized overheating found in standard drying methods.

The Core Advantage Vacuum drying solves the conflict between removing solvents and preserving catalyst structure. By utilizing negative pressure rather than excessive heat, it locks active sites in place and ensures the metal precursors remain highly dispersed for the subsequent calcination phase.

The Physics of Low-Temperature Preservation

Lowering the Boiling Point

The fundamental mechanism at work is the relationship between pressure and the boiling point of liquids. A vacuum environment significantly reduces the pressure surrounding the catalyst precursor.

This allows solvents to evaporate rapidly at much lower temperatures, such as 70°C. You achieve efficient drying without subjecting the delicate precursor structure to the thermal stress of standard atmospheric drying.

Preventing Localized Overheating

Standard drying ovens rely on convection, which can create hot spots or uneven temperature gradients within the powder bed.

Vacuum drying mitigates this risk entirely. By operating at a lower overall temperature, it eliminates the "localized overheating" that causes metal particles to sinter (clump together) prematurely.

Controlling Catalyst Morphology

Halting Component Migration

One of the biggest risks during the drying of impregnated supports is capillary action. As solvents evaporate in a standard oven, they can drag metal ions from the pores to the outer surface.

Vacuum drying removes the solvent so efficiently and at such low thermal energy that this migration is minimized. It stabilizes the spatial distribution of the precursor, keeping the platinum where you deposited it—deep within the support pores or evenly across the surface.

Ensuring Optimal Dispersion

For Platinum (Pt) based catalysts, activity is directly linked to surface area. You need small, separated nanoparticles, not large agglomerates.

By preventing the pre-aggregation of active components during the drying phase, the vacuum method ensures the material enters the high-temperature calcination stage with a "loose" and highly dispersed structure. This directly translates to a higher electrochemically active surface area (ECSA) in the final product.

Protection Against Environmental Contaminants

Excluding Oxygen and Moisture

While the primary goal is solvent removal, the vacuum environment offers a secondary benefit: isolation.

Standard air drying exposes the precursor to atmospheric oxygen and humidity, which can lead to unwanted hydrolysis or oxidation of the support. Vacuum drying excludes these factors, preserving the chemical integrity of the precursor and preventing the deactivation of surface functional groups.

Understanding the Trade-offs

Process Control vs. Speed

While vacuum drying is superior for quality, it requires more precise process control than a standard oven.

Dropping the pressure too rapidly can cause "bumping" (flash boiling), where the solvent evaporates so violently it physically disrupts the powder bed. Operators must manage the vacuum ramp-rate carefully to ensure evaporation is rapid but controlled.

Equipment Complexity

Unlike a simple convection oven, vacuum drying introduces variables regarding seal integrity and pump maintenance.

Any leak in the system introduces atmospheric moisture, which negates the protective benefits of the vacuum. This method requires a stricter adherence to equipment maintenance schedules to ensure repeatability.

Making the Right Choice for Your Goal

When finalizing your catalyst preparation protocol, consider your specific performance metrics.

- If your primary focus is maximizing catalytic activity: Use vacuum drying to ensure the highest possible dispersion of Pt nanoparticles and prevent active site agglomeration.

- If your primary focus is material purity: Rely on the vacuum environment to protect sensitive precursors from hydrolysis or oxidation caused by atmospheric humidity.

The vacuum drying oven is not merely a drying tool; it is a structural control device. It ensures that the sophisticated nano-architecture you designed during impregnation is not destroyed by the brute force of thermal evaporation.

Summary Table:

| Feature | Standard Drying Oven | Vacuum Drying Oven |

|---|---|---|

| Mechanism | Convection & High Heat | Negative Pressure & Low Temp |

| Temperature | High (Potential Overheating) | Controlled (e.g., 70°C) |

| Metal Dispersion | High Risk of Aggregation | Superior (Prevents Migration) |

| Morphology | Capillary Action Risks | Locked-in Nano-architecture |

| Environment | Exposed to Oxygen/Moisture | Isolated & Protected |

| Key Outcome | Reduced Active Surface Area | High ECSA & Activity |

Maximize Your Catalyst Performance with KINTEK

Don't let thermal stress compromise your research. KINTEK’s advanced Vacuum Drying Ovens provide the precise pressure control and temperature uniformity required to maintain high metal dispersion and prevent nanoparticle aggregation in Pt/Ce(M) precursors.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique lab requirements. Ensure the integrity of your nano-architecture today.

Visual Guide

References

- Matías G. Rinaudo, María R. Morales. Insights into Contribution of Active Ceria Supports to Pt-Based Catalysts: Doping Effect (Zr; Pr; Tb) on Catalytic Properties for Glycerol Selective Oxidation. DOI: 10.3390/inorganics13020032

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What factors must be controlled during furnace brazing to ensure a reliable joint? Master the 5 Key Variables for Strong Bonds

- What are the environmental benefits of vacuum furnaces? Achieve Zero Emissions & High Efficiency

- How does the retort in a hot wall furnace prevent collapsing under vacuum? Key Design Insights for Durability

- What are the primary applications of vacuum furnaces? Achieve High-Purity Heat Treatment for Aerospace and Medical

- How do vacuum degassing systems prepare PI-COFs for BET analysis? Ensure Accurate Surface Area & Pore Data

- What are the typical specifications of vertical vacuum furnaces with gas pressure quenching? Key Specs for High-Temp Processing

- How do laboratory vacuum furnaces achieve ultra-high vacuum levels? Unlock Pristine Processing Environments

- What is the function of introducing 150 Pa of argon gas into a furnace during the vacuum refining of AM60 magnesium alloy?