The primary environmental benefits of vacuum furnaces stem from two fundamental characteristics: their exceptionally clean, emission-free operation and their high energy efficiency. By heating materials in a controlled vacuum, these systems eliminate the combustion byproducts common in traditional furnaces and use advanced insulation and controls to minimize energy waste.

The core advantage of a vacuum furnace is not just that it's cleaner, but that its entire design fundamentally links environmental performance with process quality. It achieves superior results by eliminating atmospheric contaminants, a process that inherently prevents pollution and maximizes energy efficiency.

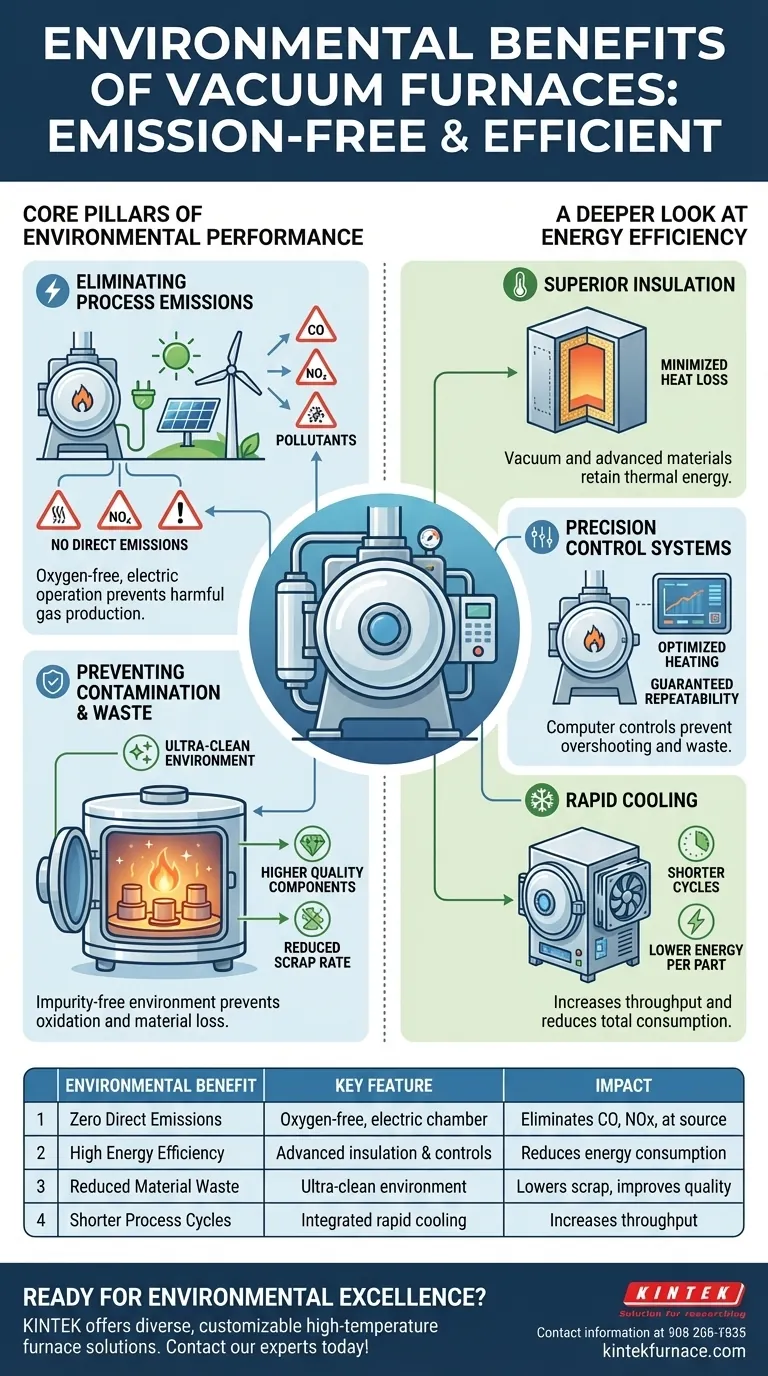

The Core Pillars of Environmental Performance

The environmental case for vacuum furnaces rests on their ability to control the entire heating environment, which directly prevents the creation of pollutants and waste.

Eliminating Process Emissions

A vacuum furnace operates without oxygen, which is essential for combustion. This means it produces no direct emissions of harmful gases like carbon monoxide (CO), nitrogen oxides (NOx), or other pollutants associated with fuel-fired furnaces.

Because they are electrically powered, all energy conversion happens cleanly within the unit. The overall environmental impact is then tied to the source of the electricity, which can be paired with renewable sources like solar for a nearly zero-carbon footprint.

Preventing Contamination and Waste

The sealed vacuum chamber provides an ultra-clean, impurity-free environment. This prevents oxidation and contamination of the parts being treated, leading to higher-quality components and significantly reducing the scrap rate.

Furthermore, the vacuum process can actually pull impurities and byproduct gases out of the material itself during heating. This results in a higher purity final product and less material waste over the entire production cycle.

A Deeper Look at Energy Efficiency

Beyond clean operation, vacuum furnaces are engineered to consume significantly less energy than their traditional counterparts. This efficiency is not an accident but a result of deliberate design choices.

The Role of Superior Insulation

Vacuum furnaces use advanced insulation materials that are highly effective at minimizing heat loss. Because a vacuum is itself an excellent insulator, the system retains thermal energy with remarkable efficiency, requiring less power to maintain high process temperatures.

Precision Control Systems

Modern vacuum furnaces feature sophisticated computer controls that manage temperature with extreme precision. This ensures energy is used only when and where it is needed, preventing the wasteful overshooting and inconsistent heating common in less advanced systems. This guarantees repeatability and optimizes energy consumption for every cycle.

Rapid Cooling for Shorter Cycles

Many vacuum furnaces are equipped with rapid cooling or quenching capabilities. By shortening the process cycle time, these systems increase throughput and reduce the total energy consumed per part, boosting both productivity and overall energy efficiency.

Understanding the Full Picture

While the benefits are significant, a complete assessment requires acknowledging the broader context and potential trade-offs.

The Upstream Energy Source

The "zero-emission" benefit is at the point of use. The furnace's true carbon footprint is dependent on the electrical grid that powers it. Operations in regions with a high percentage of fossil fuels in their energy mix will have a larger upstream footprint than those using hydro, nuclear, or renewable power.

Initial Investment and Complexity

Vacuum furnaces are highly engineered systems incorporating advanced technology. This often translates to a higher initial capital investment compared to simpler, traditional furnaces. Their operational complexity may also require more specialized training for staff.

Process Suitability

While highly versatile, a vacuum furnace is not the universal solution for every thermal process. Certain applications involving specific atmospheres or materials may be better served by other types of furnaces. The choice must always align with the specific technical requirements of the job.

Making the Right Choice for Your Operation

To determine if a vacuum furnace is the correct investment, consider your primary operational goals.

- If your primary focus is environmental compliance and emissions reduction: A vacuum furnace is an ideal choice, as it eliminates direct process emissions and harmful byproducts at your facility.

- If your primary focus is operational efficiency and long-term cost: The high energy efficiency and faster cycle times of a vacuum furnace can deliver significant savings on energy costs, often justifying the initial investment.

- If your primary focus is product quality and purity: The clean, controlled vacuum environment is unmatched for preventing contamination, which reduces waste and produces superior, high-value components.

Ultimately, adopting vacuum furnace technology is a strategic decision that aligns environmental responsibility with superior process control and efficiency.

Summary Table:

| Environmental Benefit | Key Feature | Impact |

|---|---|---|

| Zero Direct Emissions | Oxygen-free, electrically heated chamber | Eliminates CO, NOx, and other pollutants at the source |

| High Energy Efficiency | Advanced insulation & precision controls | Reduces energy consumption and operational costs |

| Reduced Material Waste | Ultra-clean, contamination-free environment | Lowers scrap rates and improves product quality |

| Shorter Process Cycles | Integrated rapid cooling systems | Increases throughput and lowers energy per part |

Ready to align your thermal processing with environmental excellence and superior efficiency?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and sustainability requirements.

Let us help you achieve zero emissions and high efficiency with a vacuum furnace tailored to your needs. Contact our experts today to discuss your application!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion