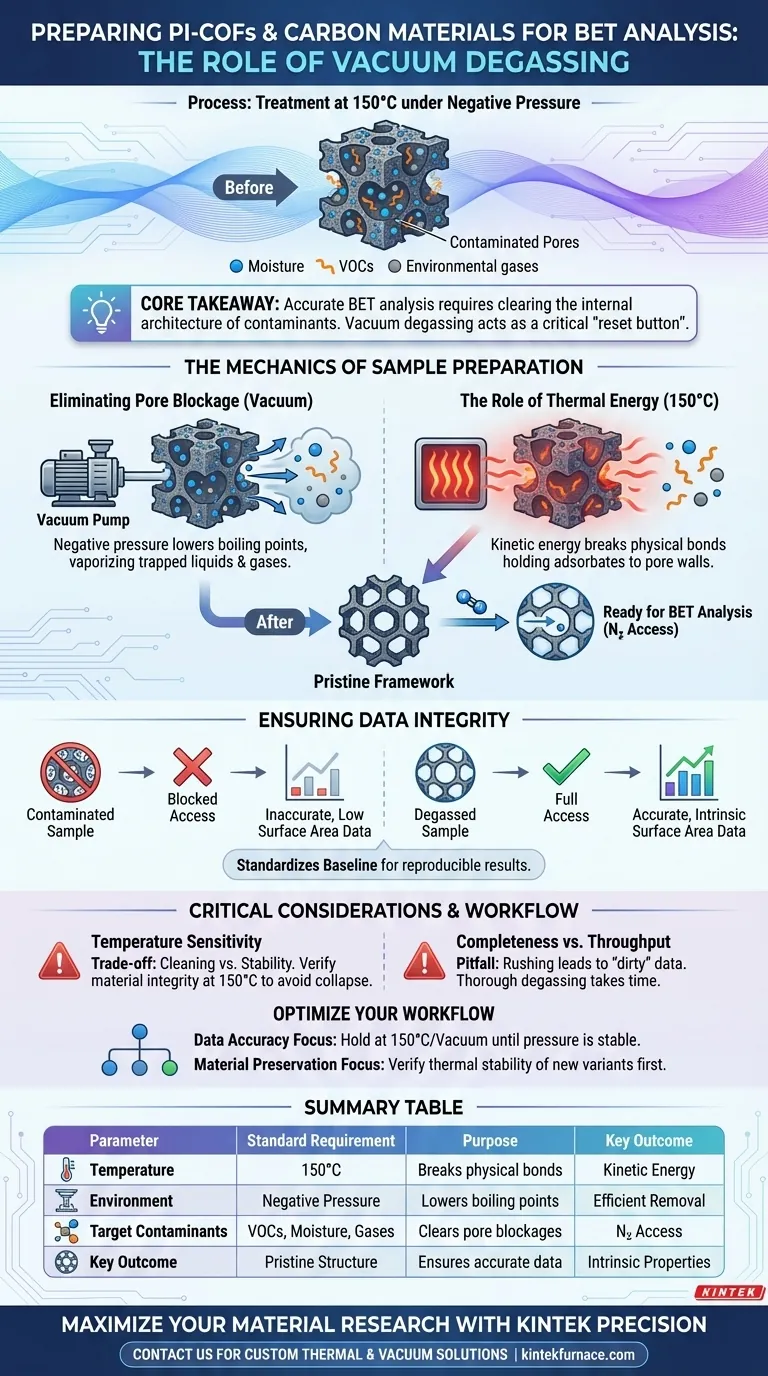

Vacuum degassing prepares Polyimide Covalent Organic Frameworks (PI-COFs) and carbon materials by treating them at 150°C under vacuum prior to analysis. This thermal and vacuum exposure systematically forces moisture, volatile organic compounds (VOCs), and trapped environmental gases out of the material's porous structure.

Core Takeaway Accurate specific surface area and pore size measurements are impossible if the pores are already filled with atmospheric contaminants. Vacuum degassing serves as a critical "reset button," clearing the material's internal architecture to ensure data reflects the framework's actual structure, not the debris trapped inside it.

The Mechanics of Sample Preparation

Eliminating Pore Blockage

Porous materials like PI-COFs and carbon derivatives act as sponges for their environment. Before analysis, their pores are often saturated with moisture and volatile organic compounds (VOCs).

A vacuum degassing system addresses this by creating a negative pressure environment. This lowers the boiling point of trapped liquids and gases, allowing them to vaporize and exit the pores.

The Role of Thermal Energy

The application of 150°C heat provides the necessary kinetic energy to break the weak physical bonds holding contaminants to the pore walls.

Without this thermal input, vacuum alone might be insufficient to dislodge tightly adsorbed molecules. The combination of heat and vacuum ensures a thorough cleaning of the internal surface area.

Ensuring Data Integrity

Revealing Intrinsic Characteristics

The primary goal of Nitrogen Adsorption-Desorption (BET) analysis is to measure the material, not its contaminants.

If pores remain blocked during analysis, the nitrogen gas cannot access the full internal volume. This results in calculated surface areas that are significantly lower than reality.

Standardizing the Baseline

Degassing creates a standardized baseline for comparison. By consistently treating samples at 150°C under vacuum, researchers ensure that variations in data are due to actual structural differences in the PI-COFs, rather than varying levels of humidity or contamination in the lab environment.

Critical Considerations and Trade-offs

Temperature Sensitivity

While 150°C is the standard for these materials, it represents a trade-off between cleaning efficiency and material stability.

You must ensure that the structural integrity of your specific carbon material or COF can withstand this temperature without collapsing. If the material degrades at 150°C, the resulting BET data will reflect a damaged structure rather than the original sample.

Completeness vs. Throughput

Thorough degassing takes time. Rushing this step to increase sample throughput is a common pitfall that leads to "dirty" data and non-reproducible results.

Optimizing Your Analysis Workflow

To ensure your BET analysis yields valid data for PI-COFs and carbon materials, consider the following approach:

- If your primary focus is Data Accuracy: Ensure the sample is held at 150°C under vacuum until the pressure remains stable, indicating no further outgassing of contaminants.

- If your primary focus is Material Preservation: Verify the thermal stability of new PI-COF variants before degassing to confirm they do not structurally degrade at the standard 150°C treatment temperature.

Effective preparation transforms a contaminated sample into a pristine framework, allowing the true properties of your material to shine through.

Summary Table:

| Parameter | Standard Requirement | Purpose in Degassing |

|---|---|---|

| Temperature | 150°C | Provides kinetic energy to break physical bonds of adsorbates. |

| Environment | Negative Pressure (Vacuum) | Lowers boiling points of contaminants for efficient removal. |

| Target Contaminants | VOCs, Moisture, Lab Gases | Clears pore blockages to allow nitrogen access. |

| Key Outcome | Pristine Internal Structure | Ensures calculated surface area reflects intrinsic properties. |

Maximize Your Material Research with KINTEK Precision

Don't let contaminated samples compromise your research data. KINTEK provides high-performance thermal and vacuum systems specifically designed to handle delicate degassing and material preparation for PI-COFs, carbon frameworks, and more.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory requirements. Ensure your BET analysis reflects the true potential of your materials with our reliable high-temp solutions.

Ready to elevate your lab's efficiency? Contact us today to find your custom solution!

Visual Guide

References

- Atsushi Nagai, Atsunori Matsuda. Synthesis and Electrical Property of Graphite Oxide-like Mesoporous <i>N</i>-Carbon Derived from Polyimide-Covalent Organic Framework Templates. DOI: 10.1021/acsomega.5c03968

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the key material requirements for crucibles used in the vacuum distillation of aluminum-magnesium alloys? Ensure High-Purity Metal Separation

- What heat treatment processes can a vacuum furnace perform? Achieve Superior Control and Clean Results

- What is the significance of vacuum sintering in metal processing, and how do continuous vacuum furnaces facilitate it? Unlock High-Purity Metal Parts

- What role does a high-vacuum heat treatment furnace play in the preparation of a GdEuZrO/YSZ double-layer coating system?

- Why are gas-based reduction shaft furnaces preferred for DRI? Maximize Efficiency with Regional Resources

- What is the role of a high-precision vacuum drying oven in biochar activation? Unlock Superior Surface Area

- How is a two-stage heating process implemented in plasma nitriding equipment? Master Surface Consistency

- How can vacuum heat treatment improve the service life of mechanical parts and tools? Boost Durability and Extend Lifespan