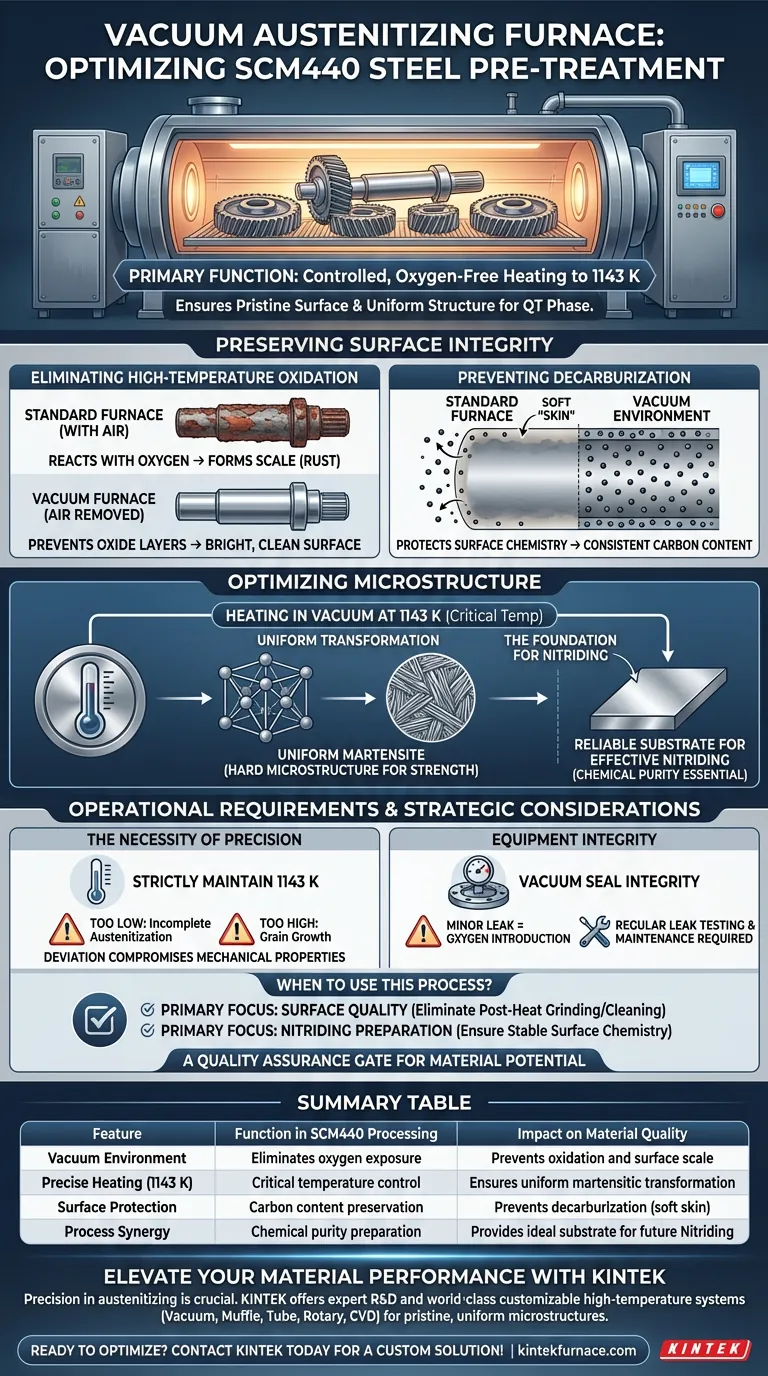

The primary function of an industrial-grade vacuum austenitizing furnace is to create a controlled, oxygen-free environment for heating SCM440 steel to precisely 1143 K during the Quenching and Tempering (QT) phase. By eliminating atmospheric exposure, this equipment ensures the steel reaches its critical transformation temperature without suffering from surface degradation.

To maximize the performance of SCM440 steel, you must treat the internal structure without damaging the exterior surface. The vacuum furnace solves this dual challenge by preventing oxidation and decarburization, delivering a pristine, uniform martensitic structure essential for future processing.

Preserving Surface Integrity

Eliminating High-Temperature Oxidation

When steel is heated to high temperatures in a standard atmosphere, it reacts with oxygen to form scale (rust).

The vacuum furnace removes air from the heating chamber. This prevents the formation of oxide layers, ensuring the steel retains a bright, clean surface throughout the heating cycle.

Preventing Decarburization

Carbon is the element responsible for the hardness and strength of SCM440 steel.

In standard furnaces, surface carbon can be leeched out into the atmosphere, leaving a soft "skin" on the part. The vacuum environment protects the surface chemistry, keeping the carbon content consistent from the core to the skin.

Optimizing Microstructure

Achieving Uniform Martensite

The specific temperature of 1143 K is critical for austenitizing SCM440.

Reaching this temperature in a vacuum allows the steel's crystal structure to transform uniformly. When the steel is subsequently quenched, it forms martensite, a hard microstructure that provides the necessary strength for industrial applications.

The Foundation for Nitriding

SCM440 is frequently subjected to nitriding (a surface hardening process) after the QT phase.

If the surface has been oxidized or decarburized during the initial heating, the nitriding process will be inconsistent or ineffective. The vacuum furnace ensures the surface is chemically pure, acting as a reliable foundation for this subsequent hardening.

Understanding the Operational Requirements

The Necessity of Precision

While vacuum furnaces offer superior quality, they require rigorous control.

The temperature must be maintained strictly at 1143 K. Any deviation can result in incomplete austenitization (too low) or grain growth (too high), compromising the mechanical properties of the steel.

Equipment Integrity

The benefits of this process rely entirely on the integrity of the vacuum seal.

Even a minor leak introduces oxygen, which defeats the purpose of the equipment. Regular maintenance and leak testing are required to ensure the "oxygen-free" status is absolute.

Strategic Considerations for SCM440 Processing

To determine if this process aligns with your manufacturing goals, consider the following:

- If your primary focus is Surface Quality: The vacuum furnace is essential to eliminate the need for aggressive post-heat-treatment grinding or cleaning to remove scale.

- If your primary focus is Nitriding Preparation: You must use vacuum austenitizing to ensure the surface chemistry acts as a stable substrate for nitrogen diffusion.

The vacuum austenitizing furnace is not merely a heating tool; it is a quality assurance gate that safeguards the material's potential before it ever undergoes final hardening.

Summary Table:

| Feature | Function in SCM440 Processing | Impact on Material Quality |

|---|---|---|

| Vacuum Environment | Eliminates oxygen exposure | Prevents oxidation and surface scale |

| Precise Heating (1143 K) | Critical temperature control | Ensures uniform martensitic transformation |

| Surface Protection | Carbon content preservation | Prevents decarburization (soft skin) |

| Process Synergy | Chemical purity preparation | Provides ideal substrate for future Nitriding |

Elevate Your Material Performance with KINTEK

Precision in the austenitizing phase is the difference between industrial-grade SCM440 and material failure. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum, Muffle, Tube, Rotary, and CVD systems designed to meet the most rigorous lab and industrial standards.

Our high-temperature furnaces are fully customizable to your specific heating cycles, ensuring you achieve a pristine, uniform microstructure every time. Whether you are prepping for nitriding or requiring oxygen-free quenching, KINTEK provides the reliability you need to safeguard your material's integrity.

Ready to optimize your heat treatment process? Contact KINTEK today for a custom solution!

Visual Guide

References

- M.H. Kim, Osamu Umezawa. Influence of Prior Quenching and Tempering Treatment on Cementite Formation during Nitriding at 913 K for SCM440 Steel. DOI: 10.2355/isijinternational.isijint-2024-367

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is a high-precision vacuum drying oven required for the preparation of high-performance supercapacitor electrodes?

- How does the heating process work in a hot wall vacuum furnace? Discover Its Indirect Heating Benefits

- What are the main benefits of using a vacuum furnace for industrial processes? Achieve Superior Material Quality & Control

- What is the working principle of a vacuum carburizing furnace? Achieve Superior Surface Hardening for Steel Parts

- What is the significance of using a vacuum drying oven for silicon electrode slurries? Achieve Robust Battery Integrity

- What is the temperature range of laboratory vacuum furnaces and what factors influence it? Find the Perfect Fit for Your Lab

- What is the heat treatment in a vacuum oven? Achieve Superior Surface & Material Integrity

- What types of heat treatment processes can a vacuum furnace support? Achieve Purity and Precision in Material Processing