At its core, a vacuum carburizing furnace hardens the surface of steel parts by first creating a clean, oxygen-free environment and then precisely introducing a carbon-rich gas. The process involves heating the steel in a vacuum to prevent unwanted reactions, followed by a controlled "boost" phase where a hydrocarbon gas provides carbon, and a "diffusion" phase where that carbon is driven deeper into the part's surface. This creates a hard, wear-resistant outer layer while maintaining a softer, more ductile core.

The fundamental principle is not just heating, but a carefully controlled chemical reaction. The vacuum's primary role is to act as a perfect, ultra-clean slate, ensuring the carbon atoms introduced are the only active elements reacting with the steel surface for highly predictable and superior results.

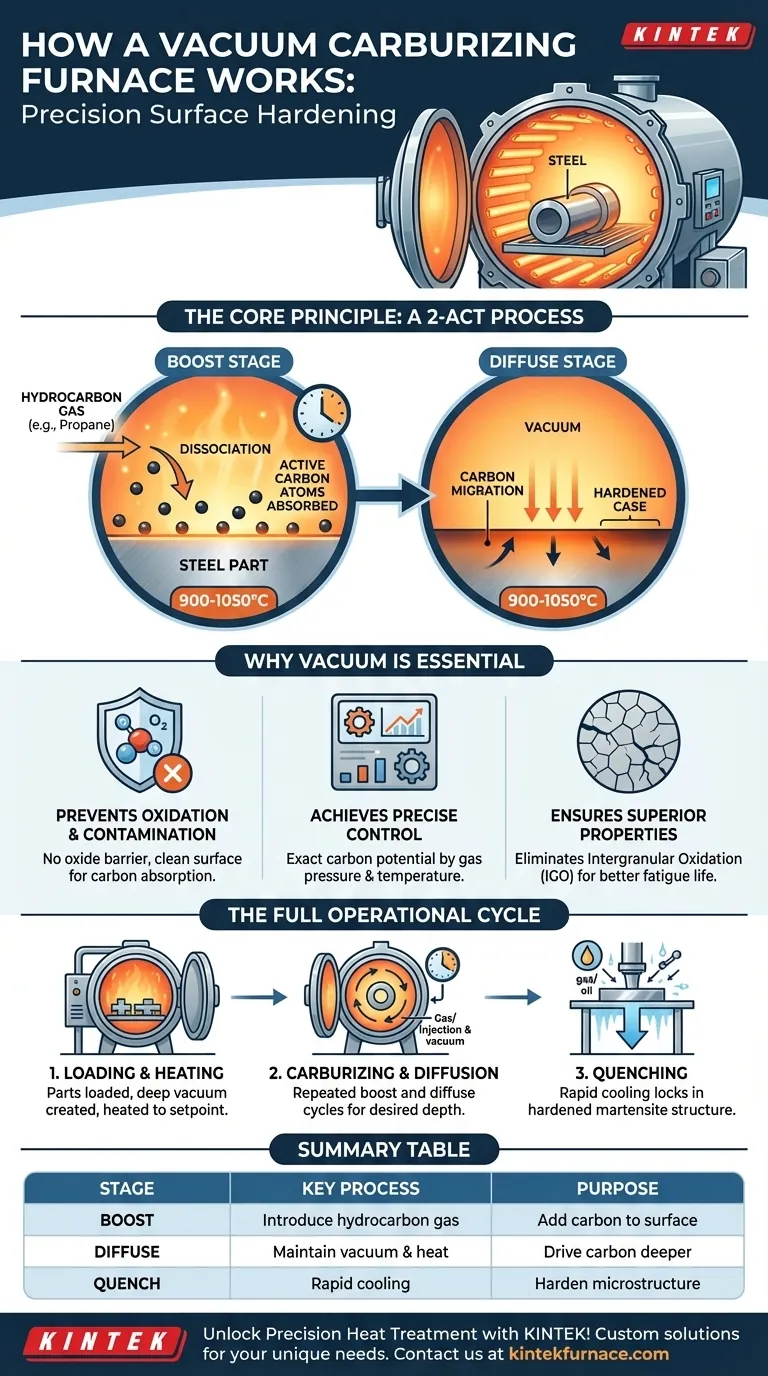

The Core Principle: A Two-Act Process

Vacuum carburizing is a case-hardening process that fundamentally alters the surface chemistry of steel. It operates in two distinct but complementary stages: the "boost" and the "diffuse" cycles, both performed at high temperatures (typically 900-1050°C).

The "Boost" Stage: Introducing Carbon

Once the furnace reaches the target temperature under vacuum, the boost stage begins. A small, precisely measured amount of a hydrocarbon gas, such as propane or acetylene, is introduced into the chamber at low pressure.

The intense heat causes this gas to break down, or dissociate, releasing highly active carbon atoms. These atoms are then readily absorbed by the clean, hot surface of the steel part.

The "Diffuse" Stage: Driving the Carbon Deeper

After a set period, the flow of hydrocarbon gas is stopped, and the furnace is evacuated again. This is the diffusion stage.

No new carbon is added to the surface. Instead, the high temperature is maintained, allowing the high concentration of carbon atoms at the immediate surface to migrate deeper into the material. This creates a smooth, gradual transition in carbon content, forming the hardened "case" to a specified depth. These boost/diffuse cycles can be repeated to achieve a precise carbon profile.

Why a Vacuum is Essential

Using a vacuum is not incidental; it is central to the process's effectiveness and the quality of the final product. The vacuum environment provides several critical advantages over traditional atmospheric carburizing.

Preventing Oxidation and Contamination

The primary function of the vacuum is to remove air, specifically oxygen and water vapor, from the heating chamber. This prevents the formation of oxide layers on the steel's surface.

An oxide layer would act as a barrier, blocking or inhibiting the absorption of carbon. A perfectly clean surface, achievable only in a vacuum, is essential for uniform and efficient carburizing.

Achieving Precise Process Control

In a vacuum, the furnace atmosphere is completely controlled. The only gases present are those intentionally introduced.

This allows for extremely precise management of the carbon potential—the ability of the atmosphere to transfer carbon to the steel. The process is determined solely by gas pressure and temperature, making it highly repeatable and predictable.

Ensuring Superior Material Properties

The absence of oxygen prevents a defect known as intergranular oxidation (IGO), which is common in atmospheric carburizing. IGO can create microscopic weak points in the material's grain structure, reducing fatigue life.

By eliminating this, vacuum carburizing produces parts with superior fatigue strength and overall performance.

The Full Operational Cycle

The boost-and-diffuse stages are the heart of the process, but they fit within a larger operational sequence.

Stage 1: Loading and Heating

Workpieces are loaded into the furnace. The chamber is sealed, and a powerful vacuum system pumps out the air. Once a deep vacuum is achieved, heating elements raise the temperature of the workload to the setpoint.

Stage 2: Carburizing and Diffusion

The furnace executes the pre-programmed series of boost (gas injection) and diffuse (vacuum) cycles until the desired case depth and carbon profile are achieved.

Stage 3: Quenching

After the final diffusion stage, the parts must be cooled rapidly (quenched) to lock in the desired hardened microstructure (martensite).

Modern vacuum furnaces often integrate this step, using either high-pressure gas quenching (HPGQ) or an attached, vacuum-sealed oil bath. This rapid cooling transforms the high-carbon surface into a very hard, wear-resistant layer.

Understanding the Trade-offs

While powerful, vacuum carburizing is not the solution for every application. It is important to understand its limitations.

Higher Equipment and Maintenance Costs

Vacuum furnaces are technologically more complex than their atmospheric counterparts. The initial investment is significantly higher, and maintaining vacuum pumps, seals, and control systems requires specialized expertise.

Potentially Longer Cycle Times

The need to pump the chamber down to a deep vacuum at the beginning of the cycle can add time compared to simply purging an atmospheric furnace with gas. However, the ability to operate at higher temperatures often offsets this, reducing the time needed for the carburizing stages.

Making the Right Choice for Your Goal

Selecting the correct heat treatment process depends entirely on the performance requirements and cost constraints of your component.

- If your primary focus is high-performance, complex geometries, or distortion-sensitive parts: Vacuum carburizing is the superior choice for its cleanliness, precision, and ability to produce parts with enhanced fatigue life.

- If your primary focus is high-volume, low-cost production of simple components: Traditional atmospheric carburizing may remain a more cost-effective solution, provided the lower process control and risk of IGO are acceptable.

Understanding the principles of vacuum carburizing empowers you to specify the optimal heat treatment for achieving superior material properties and final part performance.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| Boost | Introduce hydrocarbon gas (e.g., propane) | Add carbon atoms to steel surface |

| Diffuse | Maintain vacuum and heat | Drive carbon deeper for uniform case depth |

| Quench | Rapid cooling (e.g., gas or oil) | Harden surface microstructure |

Unlock Precision Heat Treatment with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior results with tailored vacuum carburizing solutions!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties