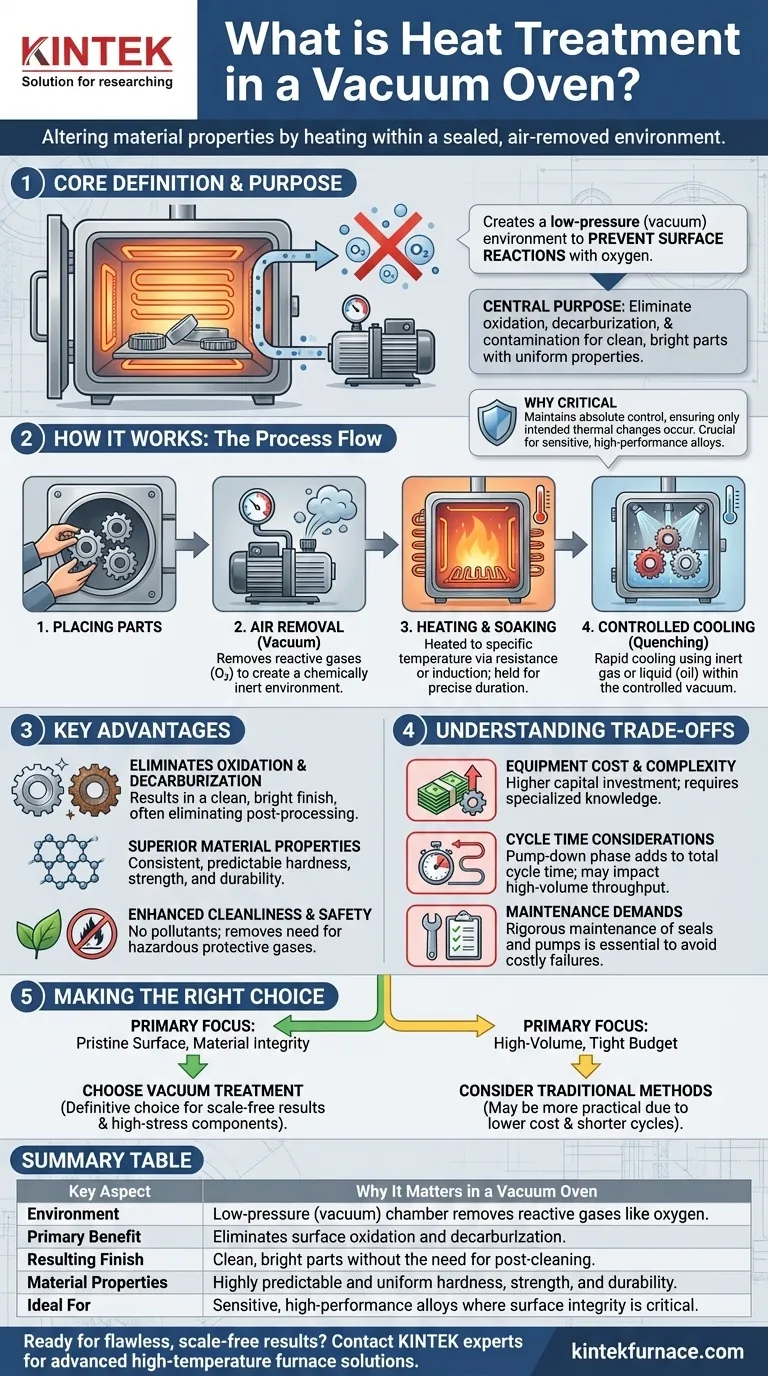

At its core, vacuum heat treatment is a process of altering a material's properties by heating it within a sealed furnace from which the air has been removed. By creating a low-pressure, or vacuum, environment, the process fundamentally prevents the material's surface from reacting with atmospheric elements like oxygen during the intense heating and cooling cycles.

The central purpose of using a vacuum is to eliminate oxidation, decarburization, and other surface contamination. This results in parts with a clean, bright finish and highly predictable, uniform metallurgical properties that are difficult to achieve with traditional atmospheric methods.

How Vacuum Heat Treatment Fundamentally Works

To understand the value of this process, you must first grasp the role the vacuum plays. It isn't just about heating; it's about creating a chemically inert environment.

The Principle of Removing Air

The process begins by placing parts inside a sealed furnace chamber. A powerful vacuum pump system then extracts the air, significantly reducing the internal pressure.

By removing the air, you remove the reactive gases—primarily oxygen—that would otherwise cause scaling (oxidation) and carbon loss (decarburization) on the metal's surface at high temperatures.

The Heating and Cooling Cycle

Once the desired vacuum level is reached, the material is heated to a specific temperature. This can be achieved through conventional resistance elements or advanced methods like induction heating, where an electromagnetic field heats the part directly.

After being held at temperature for a precise duration (a step known as soaking), the material is cooled in a highly controlled manner. This cooling, or quenching, can be done using high-pressure inert gas (gas quenching) or liquids like oil, all within the controlled furnace environment.

Why the Vacuum is Critical

The vacuum is maintained throughout the heating and soaking phases. This ensures that the only changes occurring in the material are those intended by the thermal cycle itself, not from unwanted chemical reactions with an atmosphere.

This absolute control is what allows for the treatment of sensitive, high-performance alloys where surface integrity is paramount.

The Key Advantages Over Traditional Methods

Choosing vacuum treatment is a decision driven by the need for superior quality and consistency. The benefits are a direct result of eliminating atmospheric interference.

Eliminating Oxidation and Decarburization

This is the most significant advantage. Parts emerge from the furnace with a clean and bright surface, free of the scale that forms in atmospheric furnaces. This often eliminates the need for costly and labor-intensive post-processing steps like sandblasting or chemical cleaning.

Furthermore, for high-carbon steels, preventing decarburization is critical for maintaining surface hardness and wear resistance.

Achieving Superior Material Properties

The uniform heating and controlled quenching in a vacuum environment lead to more consistent and predictable metallurgical structures. This translates to reliable improvements in hardness, strength, and durability across the entire part and from batch to batch.

Enhancing Process Cleanliness and Safety

Vacuum furnaces are inherently clean and do not produce pollutants. They also eliminate the need to handle and store large volumes of potentially flammable or costly protective gases, such as hydrogen or argon, which are used in some atmospheric processes.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution. A clear-eyed assessment of its downsides is necessary for making an informed decision.

Equipment Cost and Complexity

Vacuum furnaces and their associated pumping systems represent a significantly higher capital investment than most traditional atmospheric furnaces. The technology is more complex and requires a higher level of operational knowledge.

Cycle Time Considerations

Achieving a deep vacuum takes time. The pump-down phase can add to the total cycle time, which may be a critical factor in high-volume production environments where throughput is the primary driver.

Maintenance Demands

The seals, pumps, and sophisticated control systems of a vacuum furnace require a rigorous and specialized preventative maintenance schedule. Failure to maintain the vacuum integrity can compromise the entire process and lead to costly rework or scrap.

Making the Right Choice for Your Goal

Your specific objective determines whether vacuum heat treatment is the appropriate and cost-effective choice for your application.

- If your primary focus is pristine surface finish and part cleanliness: Vacuum treatment is the definitive choice for a bright, scale-free result that requires minimal to no post-processing.

- If your primary focus is maximum performance and material integrity: The process's ability to prevent decarburization and ensure uniform properties is essential for high-stress components and advanced alloys.

- If your primary focus is high-volume production on a tight budget: The higher initial cost and potentially longer cycle times of vacuum equipment may make traditional atmospheric furnaces a more practical option.

Ultimately, choosing vacuum heat treatment is an investment in unparalleled control and final-part quality.

Summary Table:

| Key Aspect | Why It Matters in a Vacuum Oven |

|---|---|

| Environment | Low-pressure (vacuum) chamber removes reactive gases like oxygen. |

| Primary Benefit | Eliminates surface oxidation and decarburization. |

| Resulting Finish | Clean, bright parts without the need for post-cleaning. |

| Material Properties | Highly predictable and uniform hardness, strength, and durability. |

| Ideal For | Sensitive, high-performance alloys where surface integrity is critical. |

Ready to achieve flawless, scale-free results with your heat treatment processes?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Whether you require a standard Muffle or Tube Furnace, or a highly customized Vacuum or Atmosphere Furnace, our deep customization capabilities ensure your specific experimental and production requirements are met precisely.

Contact our experts today to discuss how our vacuum furnace solutions can enhance your lab's capabilities and product quality.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity