At its core, a vacuum furnace provides a level of environmental control that is simply unattainable in a traditional atmosphere-based system. Its primary advantages are the creation of a contamination-free environment that prevents oxidation, enables extremely precise temperature control and uniformity, and allows for computer-controlled processes that produce consistent, repeatable results for high-performance materials.

The fundamental advantage of a vacuum furnace isn't just one feature, but how it transforms heat treatment from a brute-force process into a precise science. By removing the reactive and unpredictable variable of atmospheric gas, you gain absolute control over the material's environment, leading to superior quality and reliability.

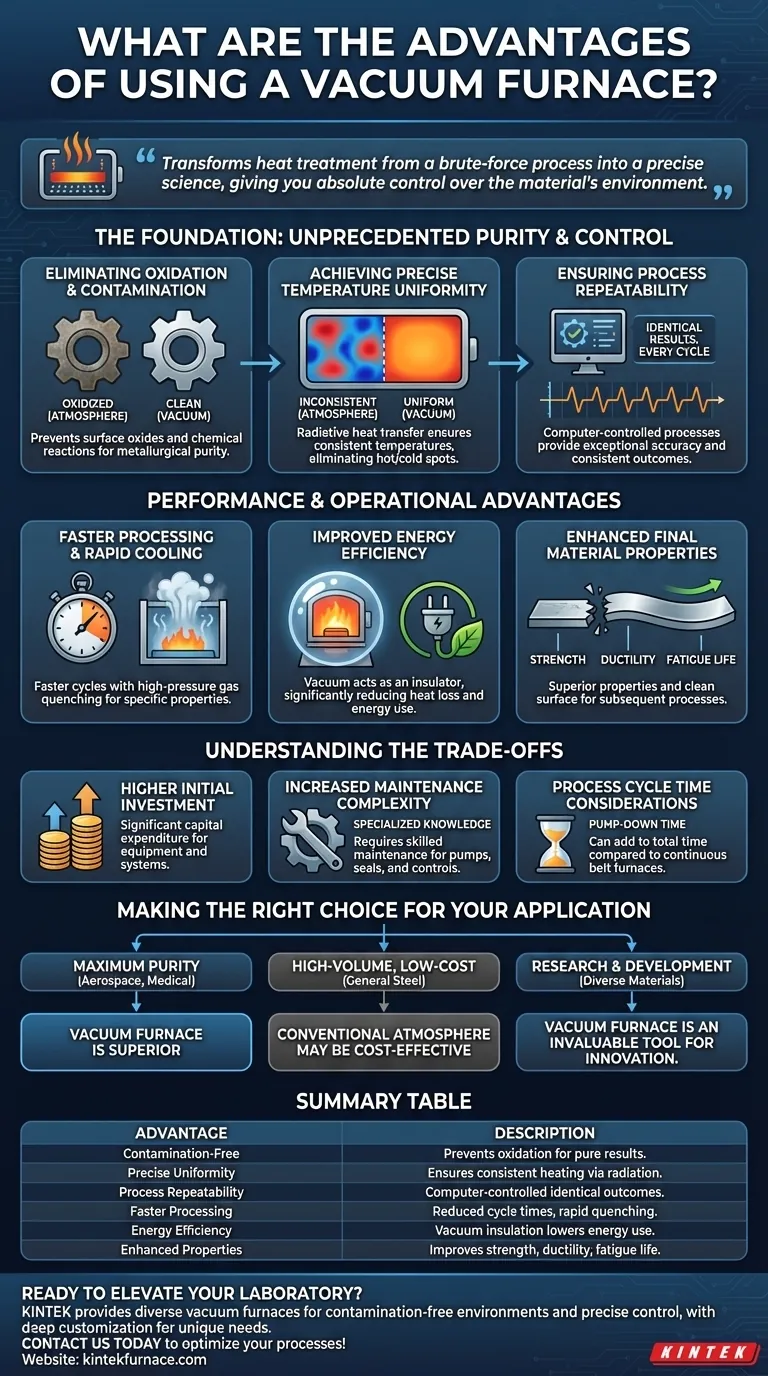

The Foundation: Unprecedented Purity and Control

The defining characteristic of a vacuum furnace is the removal of air and other gases. This simple act fundamentally changes the heat-treating process, moving it from an approximation to a highly controlled scientific procedure.

Eliminating Oxidation and Contamination

By operating at a negative pressure, a vacuum furnace removes virtually all oxygen and other reactive gases from the chamber.

This prevents the formation of oxides on the surface of a material, resulting in a clean, bright finish without the need for post-process cleaning. It also stops unwanted chemical reactions, ensuring the final product maintains its intended metallurgical purity.

Achieving Precise Temperature Uniformity

In a conventional furnace, air currents create hot and cold spots, leading to inconsistent heating. A vacuum, however, is an excellent insulator.

Heat transfer occurs primarily through radiation, which is far more uniform across the entire workload. This results in highly consistent temperatures, often within a few degrees, ensuring that every part of the component receives the exact same thermal treatment.

Ensuring Process Repeatability

With the atmosphere no longer a variable, the entire process can be managed by computer control with exceptional accuracy.

Heating rates, soak times, temperature setpoints, and cooling cycles can be programmed and executed identically every single time. This metallurgical repeatability is critical for industries like aerospace, medical, and electronics, where component failure is not an option.

Performance and Operational Advantages

The control offered by a vacuum environment directly translates into tangible benefits for performance, efficiency, and the quality of the final product.

Faster Processing and Rapid Cooling

Because there is no need to introduce and stabilize a specific gas atmosphere, the overall cycle time can be faster.

More importantly, many vacuum furnaces are equipped with high-pressure gas quenching systems. This allows for extremely rapid and controlled cooling (quenching) of the material, a critical step for developing specific hardness and strength characteristics.

Improved Energy Efficiency

The vacuum inside the furnace acts as a highly effective thermal insulator, drastically reducing heat loss to the outside environment.

This means less energy is wasted maintaining the target temperature, making vacuum furnaces more energy-efficient than many of their atmosphere-based counterparts during the heating and soaking stages.

Enhancing Final Material Properties

The combination of a pure environment, uniform heating, and controlled cooling leads to superior material properties.

Materials treated in a vacuum often exhibit enhanced strength, ductility, and fatigue life. The absence of surface contamination also improves the performance of subsequent processes like brazing or welding.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the universal solution for all heat treatment needs. Objectivity requires acknowledging their specific challenges.

Higher Initial Investment

Vacuum furnaces, with their associated pumps, seals, and complex control systems, represent a significantly higher capital expenditure compared to most standard atmosphere furnaces.

Increased Maintenance Complexity

The systems required to create and maintain a high vacuum demand specialized knowledge for maintenance and repair. Seals, pumps, and instrumentation must be kept in perfect working order to ensure performance and prevent costly downtime.

Process Cycle Time Considerations

While the heating cycle can be efficient, the time required to pump the chamber down to the desired vacuum level can add to the total process time. For very high-volume, continuous operations, this pump-down time can make it a slower option than a continuous belt furnace.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your process requirements, quality standards, and budget.

- If your primary focus is maximum material purity and performance (e.g., aerospace, medical devices, electronics): A vacuum furnace is the superior choice for its unparalleled control and contamination-free environment.

- If your primary focus is high-volume, low-cost treatment of standard alloys (e.g., general hardening of simple steel parts): A conventional atmosphere furnace may be a more cost-effective solution.

- If your primary focus is research, development, or processing diverse materials: The versatility and precise control of a vacuum furnace make it an invaluable tool for innovation.

Ultimately, choosing a vacuum furnace is a decision to prioritize absolute process control over all other factors.

Summary Table:

| Advantage | Description |

|---|---|

| Contamination-Free Environment | Prevents oxidation and chemical reactions for pure, clean results. |

| Precise Temperature Uniformity | Ensures consistent heating across materials via radiation. |

| Process Repeatability | Computer-controlled cycles for reliable, identical outcomes. |

| Faster Processing | Reduced cycle times with rapid gas quenching capabilities. |

| Energy Efficiency | Vacuum insulation minimizes heat loss, lowering energy use. |

| Enhanced Material Properties | Improves strength, ductility, and fatigue life of treated materials. |

Ready to elevate your laboratory's capabilities with advanced high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with vacuum furnaces that deliver contamination-free environments, precise temperature control, and superior material outcomes. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can optimize your heat treatment processes and drive innovation in your work!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety