In a vacuum sintering furnace, the vacuum is not created by a single pump but by a system of pumps working in sequence. The primary types used are rotary vane pumps for initial evacuation, which are then paired with either a diffusion pump or a turbomolecular pump to achieve the required high-vacuum environment. The choice between them depends on the specific material and process requirements.

The core principle is that no single pump can efficiently operate across the entire pressure range from atmospheric pressure down to a high vacuum. Therefore, a multi-stage system is employed, where a "roughing" pump creates the initial vacuum and a "high-vacuum" pump takes over to reach the final target pressure.

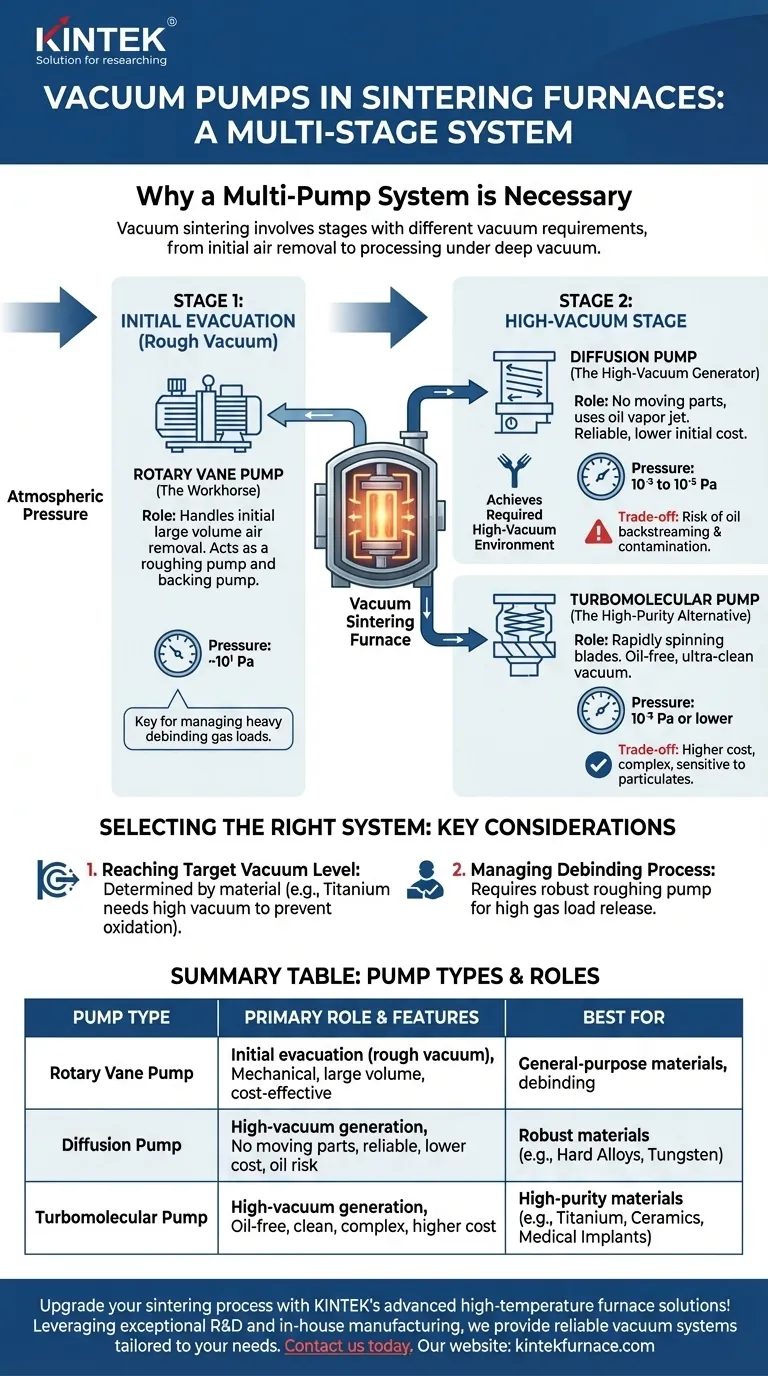

Why a Multi-Pump System is Necessary

A vacuum sintering process involves multiple stages, each requiring a different level of vacuum. A pumping system must be able to handle each stage effectively, from initial air removal to processing under deep vacuum.

The Initial Evacuation (Rough Vacuum)

The first step is to remove the bulk of the air from the furnace chamber. This brings the pressure from atmospheric down to a level where a high-vacuum pump can begin to operate efficiently. This is known as the "rough vacuum" stage.

The High-Vacuum Stage

Once a rough vacuum is achieved, a different type of pump takes over to remove the remaining gas molecules. This creates the high-vacuum (low-pressure) environment needed to prevent oxidation and ensure material purity during sintering.

The Role of Each Pump in the System

The combination of pumps is engineered to work as a team, handing off the workload as the pressure inside the furnace drops.

The Rotary Vane Pump (The Workhorse)

The rotary vane pump is the foundation of the system. It is a mechanical pump that physically removes large volumes of gas, making it ideal for the initial evacuation from atmospheric pressure. It cannot, however, create a very deep vacuum on its own.

Its primary job is to act as a roughing pump for the chamber and as a backing pump for the high-vacuum pump, meaning it maintains a low-pressure outlet for the high-vacuum pump to exhaust into.

The Diffusion Pump (The High-Vacuum Generator)

A diffusion pump has no moving parts. It works by boiling a special oil and directing a high-velocity jet of oil vapor downward. Gas molecules from the furnace chamber diffuse into this vapor stream and are carried down and exhausted by the backing pump.

These pumps are robust, reliable, and capable of creating excellent high-vacuum levels (e.g., 10⁻³ to 10⁻⁵ Pa) cost-effectively.

The Turbomolecular Pump (The High-Purity Alternative)

A turbomolecular pump, often called a "turbo pump," operates like a jet engine turbine in reverse. It uses stacks of rapidly spinning rotor blades to mechanically strike gas molecules and push them toward the exhaust, which is serviced by the backing pump.

Turbo pumps create an exceptionally clean, oil-free vacuum, making them the preferred choice for applications where even microscopic oil contamination from a diffusion pump is unacceptable.

Key Performance Requirements for Sintering

Selecting the right pump system is about more than just the type of pump; it's about meeting the critical demands of the sintering process.

Reaching the Target Vacuum Level

The required vacuum degree is determined by the material being sintered. Easily oxidized materials like titanium or refractory metals like tungsten require a high vacuum (e.g., 10⁻³ Pa or lower) to prevent reactions with residual oxygen, which would compromise the final product's integrity.

Managing the Debinding Process

Many sintering processes involve a debinding step to remove binder materials from the green part before high-temperature sintering begins. This process releases a significant amount of vaporized binder.

The vacuum system must be robust enough to handle this high gas load quickly and reliably without being overwhelmed or contaminated. A properly sized roughing pump is critical for this phase.

Understanding the Trade-offs

The choice between a diffusion pump and a turbomolecular pump is the most significant decision and involves clear trade-offs.

Diffusion Pumps: Cost vs. Contamination

Diffusion pumps are highly reliable and have a lower initial cost. Their main drawback is the risk of oil backstreaming, where oil vapor can migrate from the pump back into the furnace chamber, potentially contaminating sensitive materials. Modern baffles and traps greatly reduce this risk, but it is never zero.

Turbomolecular Pumps: Purity vs. Complexity

Turbomolecular pumps provide a completely hydrocarbon-free vacuum, which is essential for sintering high-purity ceramics, medical implants, or electronic components. However, they are more expensive, mechanically complex, and can be more sensitive to particulates or sudden air inrushes.

Selecting the Right Pump System for Your Sintering Process

Your choice should be directly aligned with your material, process, and purity goals.

- If your primary focus is general-purpose sintering of robust materials (e.g., hard alloys, tungsten): A cost-effective system using a rotary vane pump and a diffusion pump is often the most practical and reliable choice.

- If your primary focus is high-purity or contamination-sensitive materials (e.g., titanium, medical-grade components, advanced ceramics): A system with a turbomolecular pump is necessary to guarantee an oil-free environment.

- If your primary focus is a process with heavy debinding loads: Ensure the roughing pump and binder trap are adequately sized to handle the high volume of outgassing without compromising system performance.

Ultimately, a successful vacuum sintering operation depends on a pumping system that is precisely matched to the demands of the material and the process.

Summary Table:

| Pump Type | Primary Role | Key Features | Best For |

|---|---|---|---|

| Rotary Vane Pump | Initial evacuation (rough vacuum) | Mechanical, handles large gas volumes, cost-effective | General-purpose materials, debinding processes |

| Diffusion Pump | High-vacuum generation | No moving parts, reliable, lower cost, risk of oil contamination | Robust materials like hard alloys and tungsten |

| Turbomolecular Pump | High-vacuum generation | Oil-free, clean vacuum, mechanically complex, higher cost | High-purity materials like titanium, ceramics, and medical implants |

Upgrade your sintering process with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization to meet unique experimental requirements. Whether you're sintering high-purity materials or handling heavy debinding loads, we ensure optimal performance and purity. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity