At its core, precise temperature control in a vacuum furnace is the critical feature that guarantees consistent, repeatable, and high-quality results. This precision transforms complex thermal processes like annealing, brazing, and sintering from an art into a reliable science, ensuring every batch meets exact material specifications.

The significance of precise temperature control extends beyond simply reaching a set point. It is about achieving exceptional temperature uniformity across the entire part and maintaining unwavering stability over time, which are the foundational requirements for modern, high-performance materials processing.

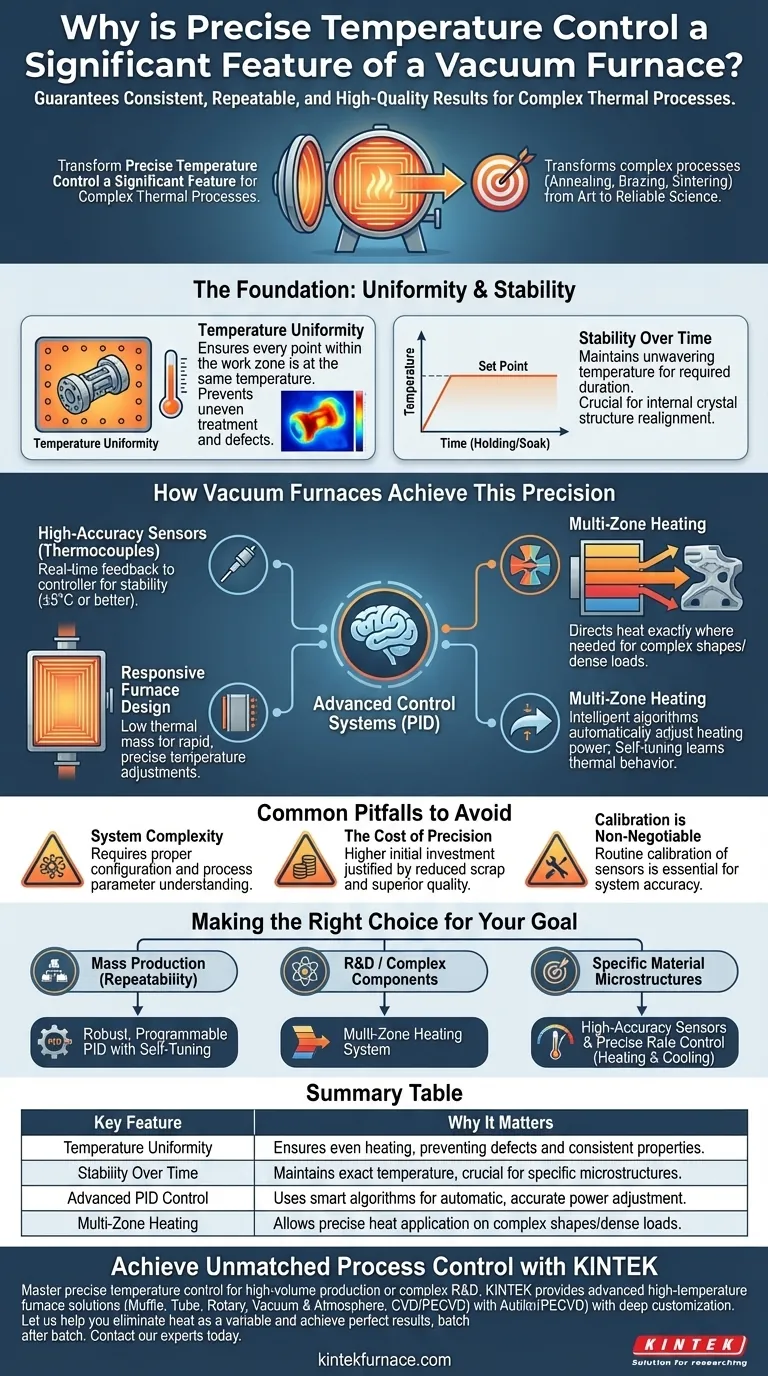

The Foundation: Uniformity and Stability

The value of a vacuum furnace is unlocked by its ability to manage heat with extreme accuracy. This is defined by two key concepts: uniformity and stability.

What is Temperature Uniformity?

Temperature uniformity ensures that every point within the furnace's work zone—and therefore on your component—is at the same temperature.

Without this, one part of a component could be perfectly treated while another is left too hard, too soft, or with internal stresses, leading to premature failure.

The Role of Stability Over Time

Stability refers to the furnace's ability to hold a specific temperature without fluctuation for a required duration (known as holding or soak time).

Many metallurgical processes depend on holding a material at a precise temperature to allow its internal crystal structure to realign. Even minor deviations can compromise the final properties of the material.

Eliminating Process Variables

By guaranteeing uniformity and stability, precise temperature control effectively removes heat as a source of error.

This makes the outcome of the thermal process highly predictable and repeatable. You can be confident that the part you produce today will be identical to the one you produce tomorrow.

How Vacuum Furnaces Achieve This Precision

This level of control isn't accidental; it's the result of an integrated system of advanced technology and intelligent design.

Advanced Control Systems (PID)

Most modern vacuum furnaces use Proportional-Integral-Derivative (PID) controllers. These are sophisticated algorithms that constantly monitor the furnace temperature, compare it to the desired setpoint, and automatically adjust the heating power to correct for any deviation.

Technologies like fuzzy logic and self-tuning further enhance this, allowing the furnace to "learn" the thermal behavior of a specific load and optimize its own performance.

High-Accuracy Sensors

A control system is only as good as the information it receives. Furnaces are equipped with highly accurate temperature sensors, such as thermocouples, that provide real-time feedback to the PID controller.

This closed-loop system ensures the controller is always acting on precise data, allowing for stability often within ±5℃ or better.

Multi-Zone Heating

For larger or more complex components, a single heating source can struggle to achieve perfect uniformity.

Many advanced furnaces feature multi-temperature zone designs. Each zone has its own sensor and heating element control, allowing the system to direct heat exactly where it's needed to accommodate complex shapes or dense loads.

Responsive Furnace Design

The physical construction of the furnace plays a critical role. Compared to older refractory furnaces, modern vacuum furnaces have chambers with low thermal mass (small heat storage).

This allows them to heat up and cool down very quickly, giving the PID controller a wide adjustment range and enabling it to execute rapid, precise changes to the temperature profile.

Common Pitfalls to Avoid

While powerful, achieving and maintaining this precision requires awareness of potential challenges.

System Complexity

Advanced control systems are powerful but require proper configuration. Understanding the parameters of your process—heating rates, holding times, and cooling rates—is essential to program the controller correctly.

The Cost of Precision

Higher precision comes at a cost. Furnaces with multi-zone heating, advanced self-tuning controllers, and high-accuracy sensors represent a larger initial investment. However, this is often justified by reduced scrap rates and superior product quality.

Calibration is Non-Negotiable

The accuracy of the entire system depends on routine calibration of its temperature sensors. An uncalibrated sensor can provide false data to the controller, leading it to maintain the wrong temperature and compromising the entire process.

Making the Right Choice for Your Goal

The level of temperature control you need is directly tied to your desired outcome.

- If your primary focus is process repeatability for mass production: Prioritize a furnace with a robust, programmable PID controller that offers self-tuning capabilities to ensure batch-to-batch consistency.

- If your primary focus is R&D or complex components: A multi-zone heating system is non-negotiable for creating specific thermal gradients and achieving uniformity on intricate shapes.

- If your primary focus is achieving specific material microstructures: Ensure the system has high-accuracy sensors and precise control over both heating and cooling rates, as the entire thermal cycle defines the final properties.

Ultimately, mastering temperature control within a vacuum furnace is the key to mastering the final properties of your material.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| Temperature Uniformity | Ensures every part of a component is heated evenly, preventing defects and ensuring consistent material properties. |

| Stability Over Time | Maintains exact temperature for required durations, crucial for achieving specific material microstructures. |

| Advanced PID Control | Uses smart algorithms to automatically adjust heating power, correcting deviations for unwavering accuracy. |

| Multi-Zone Heating | Allows for precise heat application on complex shapes or dense loads, guaranteeing uniformity across the entire workpiece. |

Achieve Unmatched Process Control with KINTEK

Mastering precise temperature control is the key to unlocking the full potential of your materials. Whether your focus is high-volume production repeatability or complex R&D projects, the right furnace is critical.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Let us help you eliminate heat as a variable and achieve perfect results, batch after batch.

Contact our experts today to discuss your specific needs and discover how a KINTEK vacuum furnace can transform your thermal processing.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today