In essence, a vacuum environment gives you unparalleled control over the heat treatment process. By removing the reactive atmosphere, it prevents surface defects like oxidation and decarburization, ensures uniform heating for consistent results, and allows for the precise thermal management required to achieve superior metallurgical properties in the finished part.

The fundamental advantage of vacuum heat treatment is not merely the absence of air, but the presence of control. By creating a chemically inert environment, you eliminate the unpredictable variables of atmospheric reactions, enabling highly repeatable and precise manipulation of a material's final properties and surface quality.

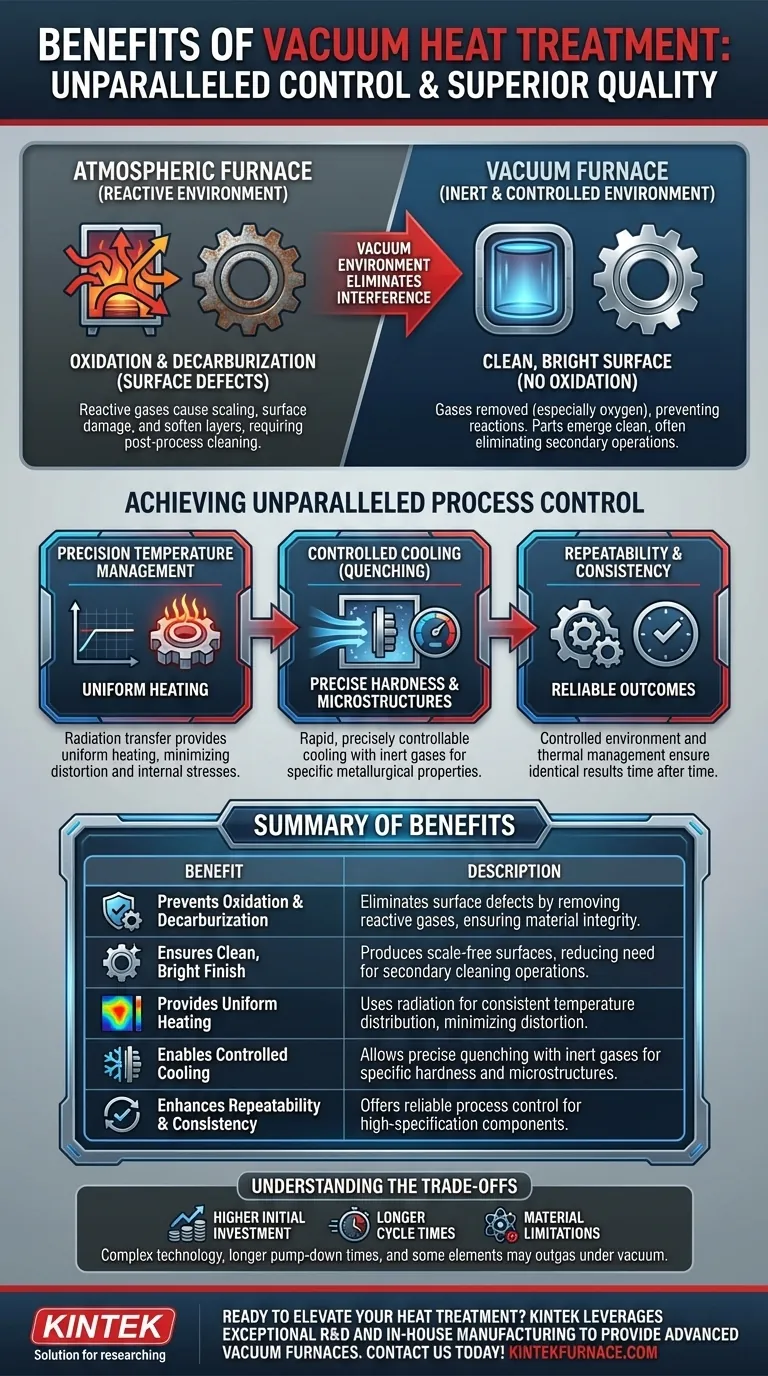

The Core Principle: Eliminating Atmospheric Interference

The primary function of the vacuum is to remove the gases—primarily oxygen—that cause undesirable reactions at elevated temperatures. This creates a fundamentally cleaner and more controlled processing environment.

Preventing Oxidation and Decarburization

At high temperatures, the oxygen in air reacts with the surface of a metal, forming a layer of oxide scale. This scaling damages the surface finish and can require costly post-process cleaning.

Similarly, the atmosphere can draw carbon out of the surface of steels, a process called decarburization. This softens the surface layer, degrading wear resistance and fatigue life. A vacuum environment completely prevents both of these destructive reactions.

Ensuring a Clean, Bright Surface Finish

Because oxidation is eliminated, parts emerge from a vacuum furnace with a clean, bright, and often shiny surface. This high-quality finish frequently eliminates the need for secondary operations like sandblasting, pickling, or surface grinding, saving both time and money.

Avoiding Contamination

A standard atmosphere contains moisture and other trace elements that can contaminate or negatively react with sensitive alloys. A vacuum furnace removes these potential contaminants, ensuring the material's chemical composition remains unchanged throughout the process.

Achieving Unparalleled Process Control

Beyond preventing negative reactions, a vacuum enables a level of positive control that is difficult to achieve with other methods. This leads to higher quality and more reliable outcomes.

Precision Temperature Management

Vacuum furnaces allow for extremely precise and stable temperature control. Heat is transferred primarily through radiation, which provides highly uniform heating across the entire workpiece, even for complex geometries. This prevents hot spots and cold spots that can lead to internal stresses, distortion, or inconsistent properties.

Controlled Cooling (Quenching)

Modern vacuum furnaces are integrated systems that include features for rapid cooling. After the heating cycle, a high-purity inert gas like nitrogen or argon can be introduced and circulated at high pressure to quench the part. The rate of cooling is precisely controllable, allowing metallurgists to achieve very specific hardness levels and microstructures.

Repeatability and Consistency

The combination of a controlled environment and precise thermal management makes vacuum heat treatment an extremely repeatable process. Once a successful heating and cooling profile ("recipe") is established, it can be executed identically time after time, ensuring consistent quality for high-specification components.

Understanding the Trade-offs

While powerful, vacuum technology is not a universal solution. It involves specific considerations and is best suited for certain applications.

Higher Initial Investment

Vacuum furnaces are complex machines and represent a significant capital investment compared to more conventional atmospheric furnaces. The cost of the furnace, pumping systems, and controls is typically higher.

Longer Cycle Times

The process of pumping the chamber down to the required vacuum level takes time. For some applications, this can result in longer overall cycle times compared to simply purging a furnace with an inert gas.

Material Limitations

Certain materials and alloying elements have a high vapor pressure, meaning they can "boil" or turn into a gas under vacuum at high temperatures. Elements like zinc, cadmium, lead, and even manganese in some steels can outgas, contaminating both the part and the furnace interior.

Is Vacuum Heat Treatment Right for Your Application?

Choosing the right heat treatment method depends entirely on your material, your quality requirements, and your production goals.

- If your primary focus is surface integrity and finish: Vacuum is the definitive choice for eliminating oxidation and decarburization, delivering clean, scale-free parts directly from the furnace.

- If your primary focus is achieving tight-tolerance mechanical properties: The precise temperature uniformity and controlled quenching of a vacuum furnace provide the highest level of repeatability for critical components.

- If your primary focus is versatility and safety: A single vacuum furnace can perform numerous processes (annealing, hardening, tempering, brazing) without the need for flammable or costly atmospheric gases.

Ultimately, adopting vacuum heat treatment is a strategic decision to prioritize process control and final part quality over all other variables.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation & Decarburization | Eliminates surface defects by removing reactive gases, ensuring material integrity. |

| Ensures Clean, Bright Finish | Produces scale-free surfaces, reducing need for secondary cleaning operations. |

| Provides Uniform Heating | Uses radiation for consistent temperature distribution, minimizing distortion. |

| Enables Controlled Cooling | Allows precise quenching with inert gases for specific hardness and microstructures. |

| Enhances Repeatability & Consistency | Offers reliable process control for high-specification components. |

Ready to elevate your heat treatment process with precision and control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our vacuum furnaces can deliver superior metallurgical properties and cost savings for your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics