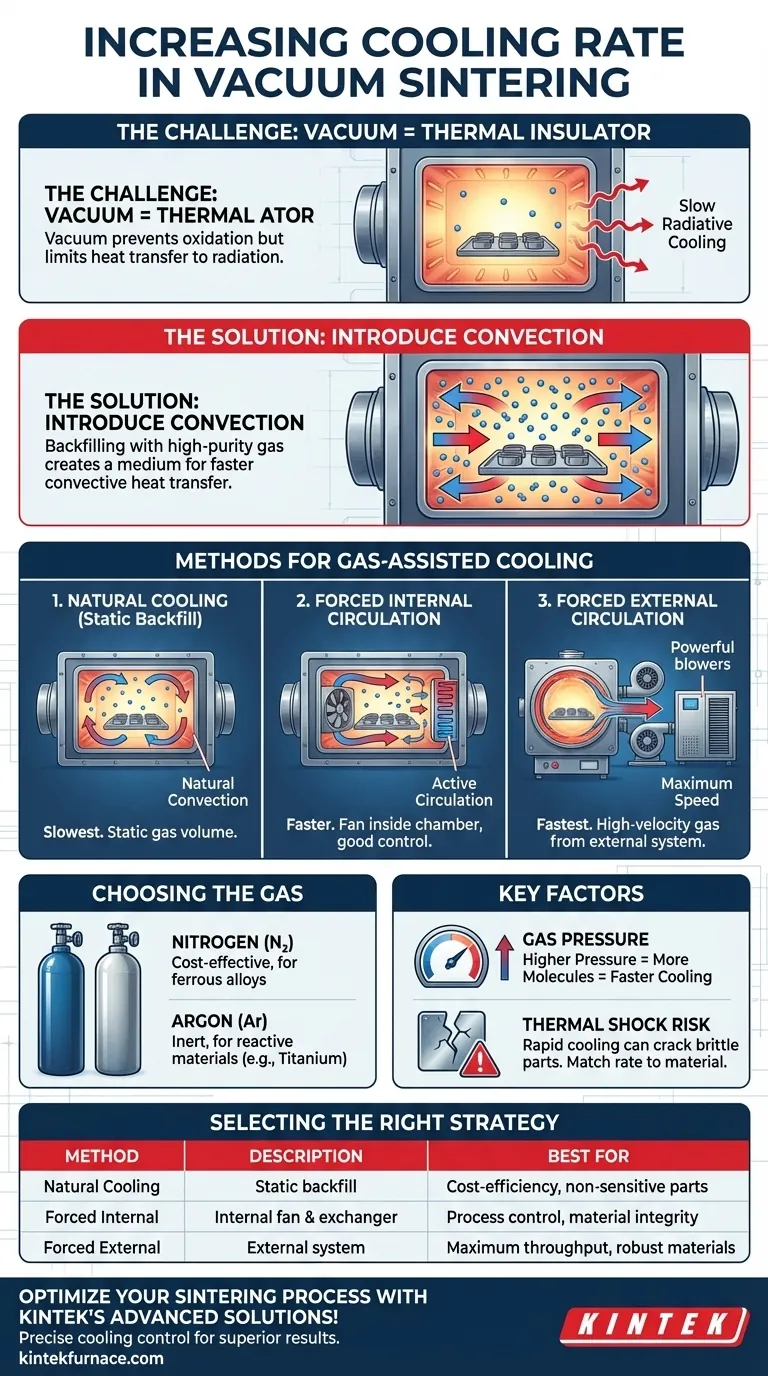

To increase the cooling rate in vacuum sintering, you must introduce a high-purity gas into the furnace chamber after the heating cycle is complete. A vacuum is a powerful thermal insulator, meaning heat dissipates very slowly through radiation alone. By backfilling the chamber with a gas like nitrogen or argon, you create a medium for much faster convective heat transfer, which can be accelerated further with forced circulation.

The core challenge of vacuum sintering is that the environment ideal for the process (a vacuum) is inherently poor for rapid cooling. The solution is to intentionally shift from slow radiative cooling to efficient convective cooling by introducing a circulating gas.

The Core Problem: Heat Transfer in a Vacuum

Why a Vacuum Creates a Cooling Bottleneck

A vacuum environment is essential for high-quality sintering. It prevents oxidation and removes trapped gases, which enhances the density, strength, and integrity of the final part.

However, this same vacuum becomes a significant obstacle during the cooling phase. With very few molecules to transfer thermal energy, heat can only escape the part through slow thermal radiation.

The Shift from Radiation to Convection

To overcome this, the process must transition from a vacuum to a gas-filled environment for the cooling stage.

Introducing a gas creates a medium for convection. Heat moves from the hot parts to the gas molecules, which can then be actively circulated and cooled, dramatically increasing the rate of heat removal.

Methods for Gas-Assisted Cooling

Natural Cooling (Static Backfill)

The simplest method is to backfill the furnace chamber with a static volume of high-purity gas, typically nitrogen or argon.

This allows for natural convection, where heated gas rises, cools on the chamber walls, and falls. While significantly faster than cooling in a vacuum, it is the slowest of the gas-cooling methods.

Forced Cooling: The Key to Rapid Cycles

Forced cooling uses a fan or blower to actively circulate the gas, creating a powerful and controlled cooling effect. This is the standard for high-throughput operations.

Internal Circulation

In this configuration, a high-temperature fan is located inside the furnace chamber. It circulates the gas over the workload and past a built-in heat exchanger (typically water-cooled).

This method provides a substantial increase in cooling speed and control, all within a self-contained system.

External Circulation

For the fastest possible cooling rates, an external system is used. The hot gas is drawn out of the furnace chamber, passed through a powerful external heat exchanger, and then blown back into the chamber at high velocity.

This approach offers maximum cooling power because the heat exchange system is not constrained by the size of the furnace interior.

Understanding the Trade-offs

Choosing the Right Cooling Gas

The most common cooling gases are high-purity nitrogen and argon.

Nitrogen is cost-effective and suitable for most ferrous alloys and non-reactive materials. Argon is fully inert and is required for materials that could react with nitrogen at high temperatures, such as certain titanium alloys or stainless steels.

The Critical Role of Gas Pressure

The cooling rate is directly proportional to the gas pressure. A higher pressure (e.g., 2 bar vs. 0.9 bar) means there are more gas molecules available to absorb and transfer heat away from the parts. Modern systems often use over-pressure quenching for this reason.

The Risk of Thermal Shock

The goal is not always maximum speed. Rapid cooling can induce thermal shock, leading to cracks or warping, especially in parts with complex geometries or those made from brittle materials.

The cooling rate must be carefully matched to the material's specifications to ensure dimensional stability and prevent part failure. This is why variable-speed fans are a critical feature in advanced furnaces.

Selecting the Right Cooling Strategy

Choosing the correct cooling method depends entirely on balancing production speed with the metallurgical requirements of your material.

- If your primary focus is maximum throughput for robust materials: An external circulation forced cooling system with high-pressure gas is the most effective solution.

- If your primary focus is process control and material integrity: A variable-speed internal circulation system offers a strong balance between speed and the ability to manage thermal gradients.

- If your primary focus is cost-efficiency for non-sensitive parts: A simple static gas backfill (natural cooling) is the lowest-cost option and may be sufficient for your needs.

By understanding these cooling principles, you can precisely control your sintering cycle to meet both production demands and final part specifications.

Summary Table:

| Method | Description | Best For |

|---|---|---|

| Natural Cooling | Static gas backfill for natural convection | Cost-efficiency, non-sensitive parts |

| Forced Cooling - Internal | Internal fan and heat exchanger for controlled cooling | Process control and material integrity |

| Forced Cooling - External | External system for maximum cooling power | Maximum throughput for robust materials |

Optimize your sintering process with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise cooling control to meet your unique experimental needs. Contact us today to enhance efficiency and achieve superior results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity