To be direct, a Vertical/Bottom Loading Vacuum Furnace offers two primary advantages over other designs: it significantly reduces the required factory floor space, and its configuration allows for more precise and uniform temperature control. These physical design benefits are coupled with the inherent material quality improvements that all vacuum furnaces provide.

While any vacuum furnace provides a superior, contamination-free environment for heat treatment, the vertical, bottom-loading design specifically solves the challenges of limited floor space and the need for exceptionally precise temperature monitoring for complex or tall parts.

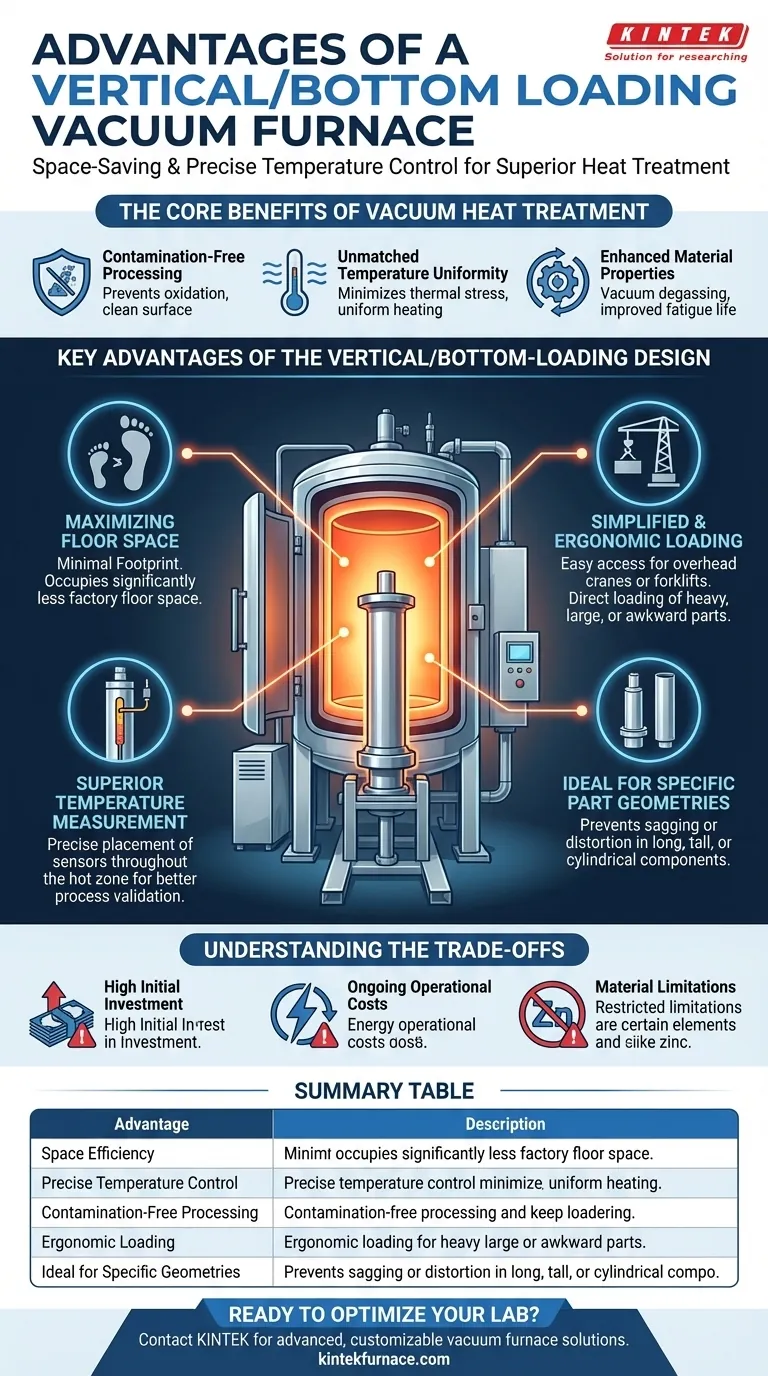

The Core Benefits of Vacuum Heat Treatment

Before focusing on the vertical design, it's critical to understand why vacuum furnaces are used in the first place. The process itself offers fundamental advantages for producing high-quality metal components.

Contamination-Free Processing

The vacuum environment is not empty; it's a highly controlled atmosphere where reactive gases like oxygen have been removed. This prevents oxidation, hydrogenation, and nitridation during the heating cycle.

The result is a bright, clean part surface and a material that retains its intended purity and chemical composition without forming undesirable surface layers.

Unmatched Temperature Uniformity

Modern vacuum furnaces utilize advanced control systems and strategically placed heating elements, often made of graphite or refractory metals like molybdenum.

Combined with the absence of air currents, this allows for exceptionally uniform heating throughout the entire workload, minimizing thermal stress and distortion in the processed parts.

Enhanced Material Properties

Processing under vacuum can actually improve the metal itself by removing dissolved gases like oxygen and hydrogen from the material's internal structure.

This "vacuum degassing" effect leads to superior mechanical properties, including improved fatigue life and ductility.

Key Advantages of the Vertical/Bottom-Loading Design

The specific orientation and loading method of a vertical furnace provide distinct operational and processing benefits.

Maximizing Floor Space

The most obvious advantage is its minimal footprint. By building the furnace chamber vertically instead of horizontally, it occupies significantly less valuable factory floor space.

Simplified and Ergonomic Loading

This design is highly convenient for loading heavy, large, or awkwardly shaped parts. The furnace bottom, or hearth, is lowered to an accessible height, allowing for direct loading with an overhead crane or forklift without complex maneuvering.

Superior Temperature Measurement

The vertical configuration allows for much easier and more accurate placement of thermocouple sensors throughout the hot zone.

Sensors can be traced from the bottom and positioned precisely within the workload, ensuring that even hard-to-reach areas are at the correct temperature. This leads to better process validation and repeatability.

Ideal for Specific Part Geometries

This design is naturally suited for processing long, tall, or cylindrical parts (such as shafts or tubes) that might sag, bend, or distort if laid flat in a horizontal furnace.

Understanding the Trade-offs

While powerful, vacuum furnaces are a significant investment with specific limitations that must be considered.

High Initial Investment

Vacuum furnaces are complex machines. The costs associated with the robust vacuum chamber, high-performance pumps, advanced heating elements, and sophisticated control systems make them more expensive than traditional atmosphere furnaces.

Ongoing Operational Costs

Creating and maintaining a high vacuum is an energy-intensive process. The electrical consumption of the vacuum pumps and heating system contributes to higher operating costs compared to non-vacuum alternatives.

Material Limitations

Certain materials, particularly those with elements that have a high vapor pressure (like zinc, cadmium, or manganese), can outgas and contaminate the furnace interior under a deep vacuum. This limits the types of alloys that can be processed effectively.

How to Apply This to Your Project

Your choice of furnace should be driven by a clear understanding of your primary goal.

- If your primary focus is optimizing a crowded facility or processing tall components: The vertical/bottom-loading furnace is the superior choice for its space efficiency and ability to handle specific part geometries.

- If your primary focus is achieving maximum material purity and uniformity: Any vacuum furnace is a strong option, but the vertical design's enhanced temperature monitoring can provide a critical advantage for highly sensitive applications.

- If your primary focus is minimizing initial capital expenditure: A traditional horizontal box vacuum furnace may be a more cost-effective solution, provided you have adequate floor space and your parts are not prone to distortion.

By understanding these fundamental trade-offs, you can select the furnace technology that precisely aligns with your operational needs and material goals.

Summary Table:

| Advantage | Description |

|---|---|

| Space Efficiency | Vertical design minimizes factory floor footprint, ideal for crowded facilities. |

| Precise Temperature Control | Easy thermocouple placement enables uniform heating and better process repeatability. |

| Contamination-Free Processing | Vacuum environment prevents oxidation and degasses materials for superior purity. |

| Ergonomic Loading | Bottom-loading simplifies handling of heavy or tall parts with cranes or forklifts. |

| Ideal for Specific Geometries | Suited for long, cylindrical parts to prevent sagging or distortion. |

Ready to optimize your lab with a high-performance vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering superior temperature control, space savings, and material quality. Contact us today to discuss how our vacuum furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency