In modern manufacturing, a vacuum chamber furnace is an indispensable tool for creating high-performance materials and components. Its common applications span a wide range of high-tech industries, including aerospace for treating jet engine parts, medical for creating biocompatible implants, and electronics for producing pure semiconductor components. These furnaces are also critical for processes like metal injection molding (MIM) and advanced ceramics, where material purity and structural integrity are paramount.

The true value of a vacuum furnace is not just heating, but providing a chemically inert environment. By removing atmospheric gases, it prevents unwanted reactions like oxidation, enabling material transformations that would be impossible in open air.

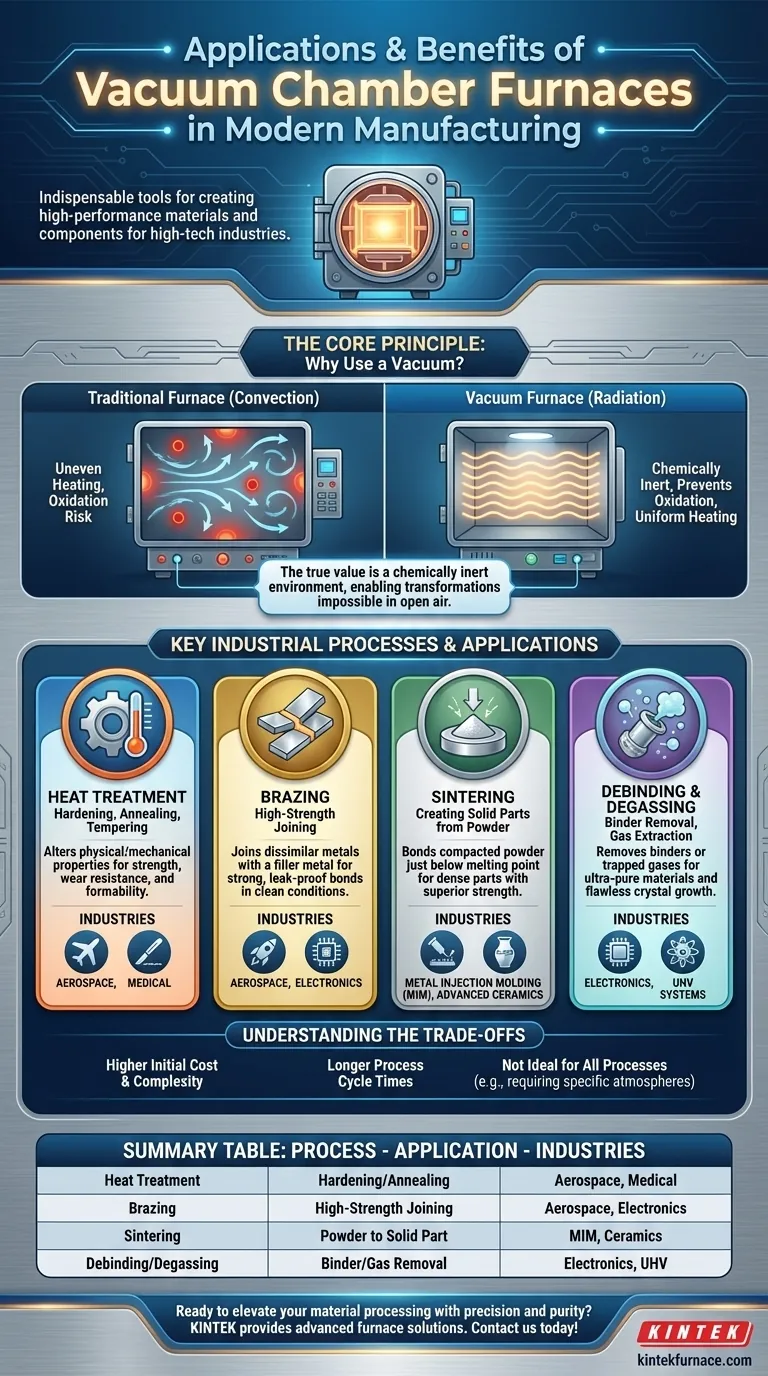

The Core Principle: Why Use a Vacuum?

The decision to use a vacuum furnace is driven by the need to control a material’s environment with absolute precision. Removing air and other gases eliminates variables that can degrade or contaminate the final product.

To Prevent Oxidation and Contamination

At high temperatures, most metals react with oxygen in the air, forming oxides on their surface. This oxidation can weaken the material, compromise joins, and ruin electrical properties.

A vacuum environment eliminates oxygen, preventing these reactions and ensuring the material's surface remains clean and its internal structure pure. This is critical for reactive metals like titanium and high-strength superalloys.

To Achieve Uniform Heating

In a traditional furnace, heat is transferred through convection (air currents), which can lead to hot spots and uneven temperatures.

In a vacuum, heat is transferred primarily through radiation. This allows for highly uniform and predictable heating of the entire part, which is essential for consistent material properties and minimizing internal stress.

To Enable High-Purity Processes

Certain advanced processes, like degassing or creating single-crystal structures for semiconductors, require an ultra-pure environment.

A vacuum furnace can pull unwanted, trapped gases out of a material (degassing) and provides the pristine conditions needed for growing flawless crystals or depositing ultra-thin films (PVD/CVD).

Key Industrial Processes and Their Applications

A vacuum furnace is a platform for executing several distinct thermal processes. The application is defined by the process being performed.

Heat Treatment (Hardening, Annealing, Tempering)

Heat treatment alters a material's physical and mechanical properties. Hardening increases strength and wear resistance, annealing softens a material to make it more formable, and tempering reduces brittleness.

These processes are fundamental in the aerospace industry for strengthening structural components and in the medical field for producing durable, fatigue-resistant surgical instruments and implants.

Brazing (High-Strength Joining)

Vacuum brazing is a process for joining materials, often dissimilar metals, using a filler metal that melts at a lower temperature.

The vacuum ensures a perfectly clean surface, allowing the filler metal to flow into the joint and create an incredibly strong, leak-proof bond. This is vital for assembling complex aerospace fuel systems and high-performance electronic packages.

Sintering (Creating Solid Parts from Powder)

Sintering is the process of heating compacted powder material to just below its melting point, causing the particles to bond together and form a solid, dense part.

This is the core technology behind metal injection molding (MIM) and advanced ceramics. The vacuum prevents contamination, resulting in a final product with superior strength and a clean surface finish.

Debinding and Degassing

Many manufacturing processes, like MIM, use a "binder" material to hold metal powder in shape. Debinding is the process of gently heating the part in a vacuum to evaporate this binder before the final sintering phase.

Degassing is used on solid materials to remove trapped gases, which is a critical step in producing components for ultra-high vacuum (UHV) systems and electronics where outgassing cannot be tolerated.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Higher Initial Cost and Complexity

Vacuum furnaces are significantly more expensive than their atmospheric counterparts. They require complex vacuum pumps, control systems, and chamber engineering, which also increases maintenance requirements.

Longer Process Cycle Times

Achieving a deep vacuum takes time (pump-down), as does cooling the part within the insulated chamber. This can result in longer overall cycle times compared to other furnace types, impacting throughput.

Not Ideal for All Processes

Some heat treatment processes, such as those requiring specific gas atmospheres (e.g., carburizing with a carbon-rich gas), are better suited for specialized atmospheric furnaces designed to handle those reactive environments.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your desired outcome.

- If your primary focus is maximum material strength and hardness: Your goal will be achieved through vacuum heat treating, such as quenching and tempering.

- If your primary focus is joining complex or dissimilar materials: You need the clean, strong bonds created by vacuum brazing.

- If your primary focus is creating complex, net-shape parts from powder: The solution is a multi-step process involving debinding and sintering.

- If your primary focus is achieving ultimate material purity for electronics or optics: You will rely on processes like degassing, high-vacuum annealing, or crystal growth.

Ultimately, a vacuum furnace empowers you to engineer materials at a fundamental level by controlling the very environment in which they are transformed.

Summary Table:

| Application | Key Process | Industries |

|---|---|---|

| Heat Treatment | Hardening, Annealing, Tempering | Aerospace, Medical |

| Brazing | High-Strength Joining | Aerospace, Electronics |

| Sintering | Powder to Solid Part Formation | Metal Injection Molding, Ceramics |

| Debinding & Degassing | Binder Removal, Gas Extraction | Electronics, UHV Systems |

Ready to elevate your material processing with precision and purity? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our vacuum furnaces can enhance your aerospace, medical, or electronics applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today