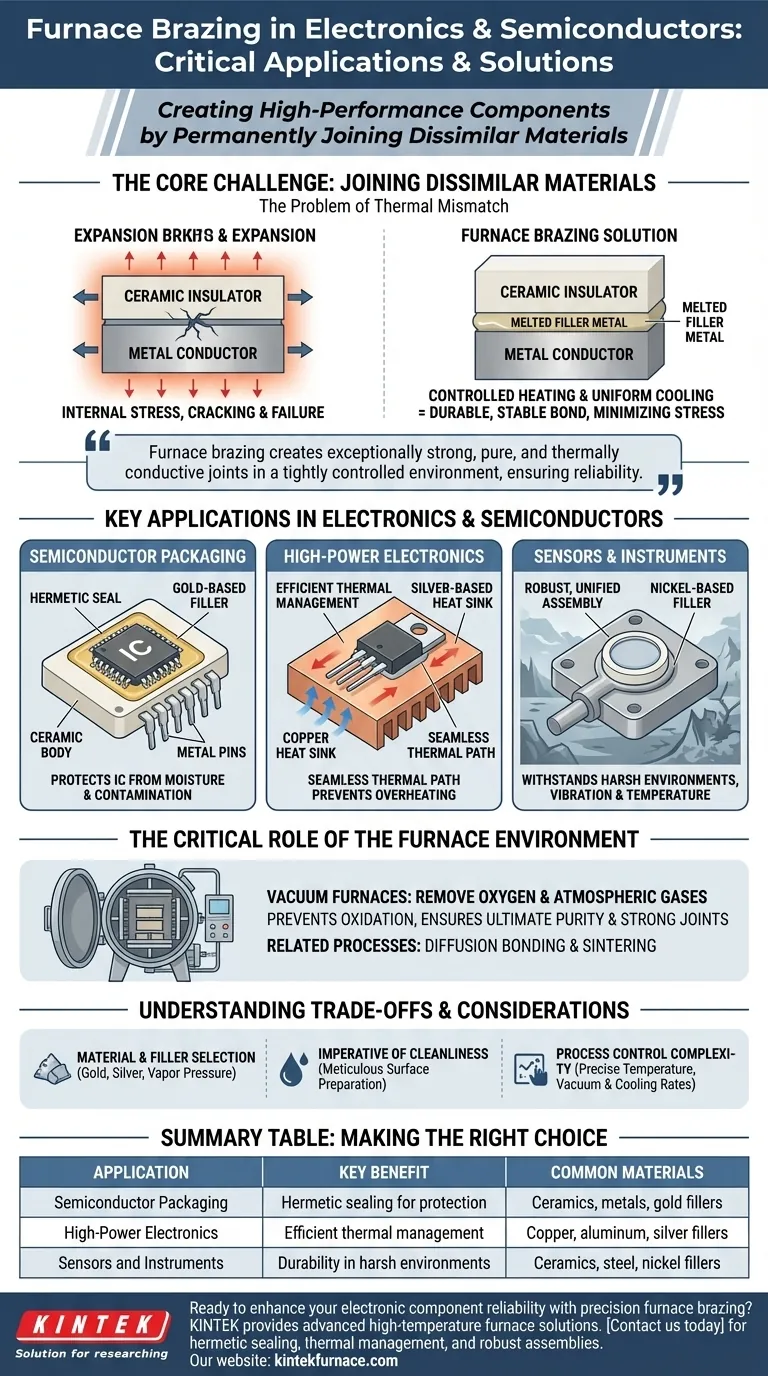

In electronics and semiconductors, furnace brazing is a critical manufacturing process used to create high-performance components by permanently joining dissimilar materials, such as ceramics to metals. Key applications include producing hermetically sealed semiconductor packages, robust sensors, and efficient thermal management solutions for high-power electronics.

The core value of furnace brazing in this high-tech field is its ability to create exceptionally strong, pure, and thermally conductive joints in a tightly controlled environment. This solves the fundamental challenge of bonding materials that expand and contract at different rates, ensuring the reliability of sensitive electronic systems.

The Core Challenge: Joining Dissimilar Materials

Furnace brazing is not just a joining method; it's a solution to a fundamental materials science problem that is prevalent in advanced electronics.

The Problem of Thermal Mismatch

Many electronic components require a combination of materials to function—for example, a ceramic insulator bonded to a metal conductor. When the device heats up during operation, these materials expand at different rates. This mismatch in thermal expansion creates immense internal stress, which can cause the component to crack, delaminate, and fail.

How Furnace Brazing Provides the Solution

Brazing joins components by melting a filler metal that flows between them via capillary action. The parent materials are heated but never melted. By using a controlled heating and cooling cycle inside a furnace, the entire assembly can be brought to temperature and cooled down uniformly, minimizing the stress caused by thermal mismatch and creating a durable, stable bond.

Key Applications in Electronics and Semiconductors

The precision and cleanliness of furnace brazing make it indispensable for manufacturing several classes of critical components.

Semiconductor Packaging

The delicate silicon inside an integrated circuit (IC) must be protected from moisture and contamination. Furnace brazing is used to create a hermetic seal, joining the ceramic body of the package to the metal pins or leads that connect it to the outside world. This ensures the long-term reliability of the semiconductor device.

High-Power Electronics

Devices like power transistors, rectifiers, and high-frequency modules generate significant heat. Furnace brazing is used to bond the active semiconductor device to a copper or aluminum heat sink. This creates a seamless, void-free thermal path that efficiently draws heat away from the component, preventing overheating and failure.

Sensors and Instruments

Many advanced sensors rely on joining a ceramic sensing element to a metal housing or electrical leads. Furnace brazing creates a robust, unified assembly that can withstand harsh environments, vibration, and temperature swings, making it ideal for critical applications in aerospace and industrial control.

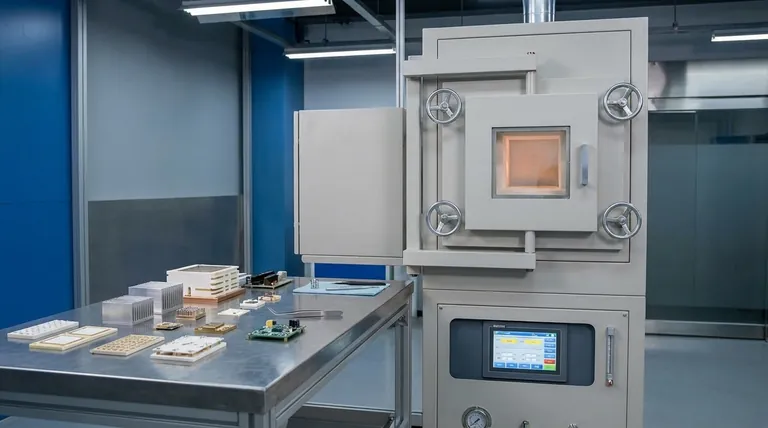

The Critical Role of the Furnace Environment

The "furnace" part of furnace brazing is what enables its use in the demanding electronics industry. The process is almost always performed in a controlled atmosphere or a vacuum.

Vacuum Furnaces for Ultimate Purity

A vacuum furnace removes oxygen and other atmospheric gases before the heating cycle begins. This prevents oxidation of the parent materials and the filler metal, resulting in an exceptionally clean and strong joint. For semiconductors, this level of purity is non-negotiable, as even microscopic contamination can alter electrical properties and cause failure.

Diffusion Bonding and Sintering

The same furnaces used for brazing can also perform related processes like diffusion bonding. This method uses high temperature and pressure to force two clean surfaces to merge at an atomic level without any filler metal. Sintering is another furnace process used to fuse powdered materials together to create solid components, often for electronic substrates.

Understanding the Trade-offs and Considerations

While powerful, furnace brazing is a sophisticated process that requires careful engineering and control.

Material and Filler Selection

The choice of filler metal is critical. Gold and silver-based fillers are common in electronics for their excellent conductivity and corrosion resistance. Materials with high vapor pressure cannot be used in a vacuum, as they would contaminate the furnace and the components.

The Imperative of Cleanliness

The success of a braze joint is entirely dependent on the cleanliness of the surfaces. Any oil, grease, or oxides must be meticulously removed before the parts enter the furnace. In electronics, where reliability is paramount, this cleaning process is a critical and multi-step procedure.

Process Control Complexity

Furnace brazing is not a simple heating operation. It requires precise control over the temperature ramp-up rate, the hold time at brazing temperature, the vacuum level, and the cooling rate. This complexity makes it a high-value but also a high-expertise manufacturing step.

Making the Right Choice for Your Application

The specific approach to furnace brazing depends entirely on the intended outcome for the electronic component.

- If your primary focus is hermetic sealing for sensitive ICs: Vacuum furnace brazing using gold-based fillers is the industry standard for creating the purest, most reliable, and corrosion-proof seals.

- If your primary focus is thermal management for power electronics: Brazing a ceramic insulator to a copper heat sink using a silver-based filler provides an excellent combination of dielectric strength and superior thermal conductivity.

- If your primary focus is creating robust sensor assemblies: Furnace brazing with a nickel-based filler is often chosen to join ceramic and steel components for maximum strength and durability in harsh industrial or automotive environments.

Mastering this process allows engineers to build more powerful, compact, and reliable electronic systems than would otherwise be possible.

Summary Table:

| Application | Key Benefit | Common Materials |

|---|---|---|

| Semiconductor Packaging | Hermetic sealing for protection | Ceramics, metals, gold fillers |

| High-Power Electronics | Efficient thermal management | Copper, aluminum, silver fillers |

| Sensors and Instruments | Durability in harsh environments | Ceramics, steel, nickel fillers |

Ready to enhance your electronic component reliability with precision furnace brazing? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for hermetic sealing, thermal management, and robust assemblies. Contact us today to discuss how we can support your high-performance electronics and semiconductor projects!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing