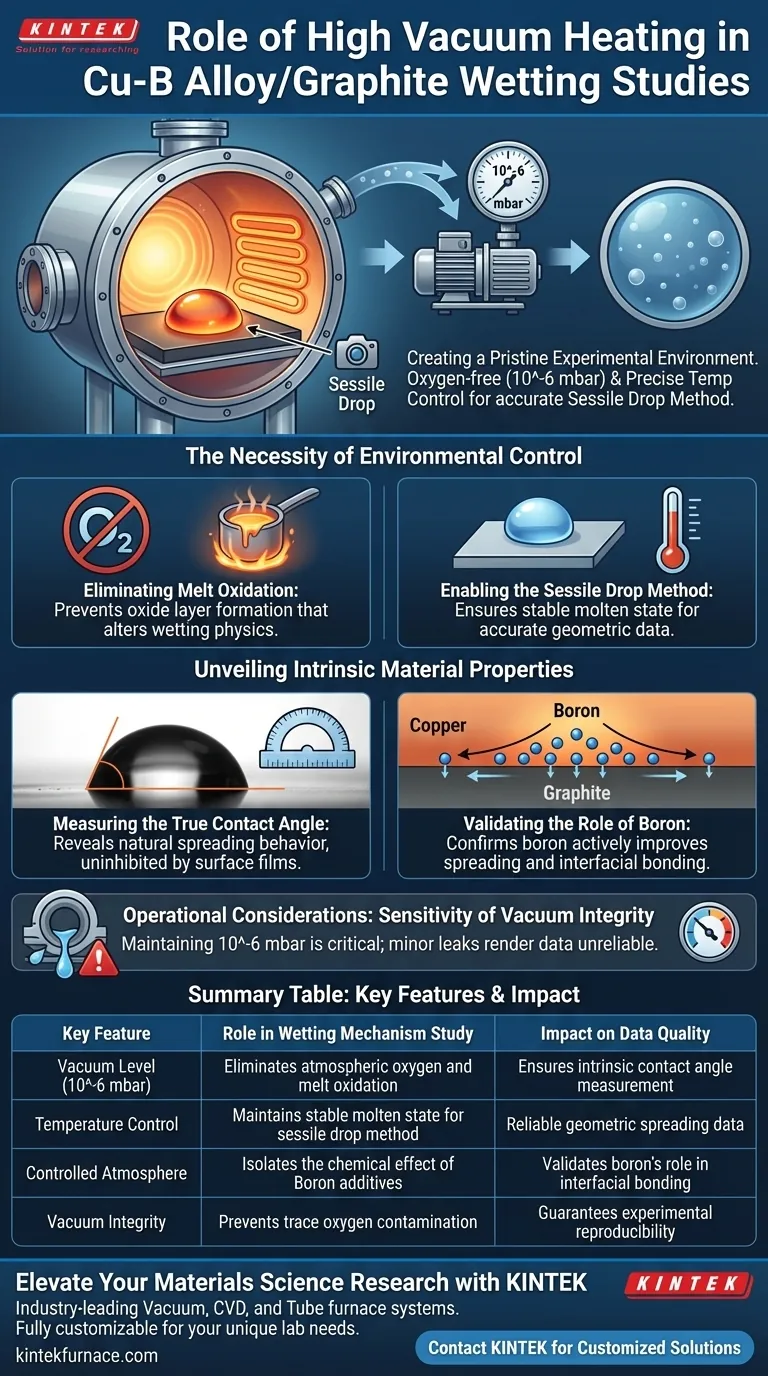

High vacuum heating equipment plays the fundamental role of creating a pristine experimental environment necessary for observing the true interaction between copper-boron alloys and graphite. By establishing a strict oxygen-free atmosphere down to 10^-6 mbar and providing precise temperature control, this equipment enables the use of the sessile drop method to accurately measure intrinsic contact angles without the distorting effects of oxidation.

Experimental accuracy in wetting studies relies entirely on eliminating environmental contamination. High vacuum heating equipment removes oxygen from the equation, confirming that improvements in spreading and interfacial bonding are caused by the boron addition, not by surface impurities.

The Necessity of Environmental Control

Eliminating Melt Oxidation

The primary function of high vacuum heating equipment is to generate a strict oxygen-free environment, typically reaching pressures as low as 10^-6 mbar.

In the absence of this vacuum, molten copper alloys react rapidly with atmospheric oxygen.

This reaction creates an oxide layer on the surface of the melt, which fundamentally alters the wetting physics and invalidates the resulting data.

Enabling the Sessile Drop Method

To study wetting mechanisms, researchers rely on the sessile drop method, which requires stable droplet formation on a substrate.

High vacuum equipment integrates precise temperature control with this method.

This ensures the alloy remains in a controlled molten state, allowing researchers to capture accurate geometric data as the droplet spreads across the graphite surface.

Unveiling Intrinsic Material Properties

Measuring the True Contact Angle

The goal of these studies is to determine the intrinsic contact angle, which serves as the primary indicator of wettability.

Only in a high-vacuum environment can the molten alloy exhibit its natural spreading behavior uninhibited by surface films.

This provides a baseline measurement that reflects the true physical chemistry between the liquid alloy and the solid graphite.

Validating the Role of Boron

Using this specialized equipment allows researchers to isolate the specific impact of adding boron to the copper matrix.

By comparing these controlled results, scientists can confirm that boron actively improves the spreading capability of the alloy.

This data directly correlates to enhanced interfacial bonding strength, a critical metric for composite material performance.

Operational Considerations and Trade-offs

The Sensitivity of Vacuum Integrity

While high vacuum heating allows for precise measurement, it introduces significant sensitivity to the experimental setup.

If the vacuum level fluctuates or fails to reach the 10^-6 mbar threshold, the presence of trace oxygen will compromise the integrity of the melt.

This makes the maintenance of seals and pumps critical; even minor leaks will render the contact angle data unreliable.

Making the Right Choice for Your Research

To ensure your wetting mechanism studies yield valid, reproducible data, consider the following specific goals:

- If your primary focus is fundamental physics: Ensure your equipment allows you to verify vacuum stability at 10^-6 mbar to guarantee the contact angle measured is intrinsic to the material.

- If your primary focus is alloy development: Use the controlled environment to incrementally test boron concentrations, isolating its specific contribution to interfacial bonding strength.

Reliable data in high-temperature wetting studies is not just about the material; it is defined by the purity of the environment in which you test it.

Summary Table:

| Key Feature | Role in Wetting Mechanism Study | Impact on Data Quality |

|---|---|---|

| Vacuum Level (10^-6 mbar) | Eliminates atmospheric oxygen and melt oxidation | Ensures intrinsic contact angle measurement |

| Temperature Control | Maintains stable molten state for sessile drop method | Reliable geometric spreading data |

| Controlled Atmosphere | Isolates the chemical effect of Boron additives | Validates boron's role in interfacial bonding |

| Vacuum Integrity | Prevents trace oxygen contamination | Guarantees experimental reproducibility |

Elevate Your Materials Science Research with KINTEK

Precision in wetting studies starts with an uncompromising environment. KINTEK provides industry-leading Vacuum, CVD, and Tube furnace systems designed to reach the strict vacuum thresholds required for high-temperature material analysis.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique laboratory needs—whether you are perfecting copper-boron alloys or developing advanced composites.

Ready to achieve superior vacuum stability and reproducible results? Contact KINTEK today to discuss your customized furnace solution!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How do computer-controlled systems enhance vacuum furnace operations? Achieve Precision and Repeatability in Heat Treatment

- What types of materials are compatible with low vacuum versus high vacuum furnaces? Choose the Right Furnace for Your Materials

- What are the advantages of using a vacuum brazing furnace over other metal joining processes? Achieve Clean, Strong, and Distortion-Free Metal Joints

- What benefits does vacuum carburizing offer for parts with complex shapes? Minimize Distortion and Boost Performance

- What are the advantages of using a vacuum oven for the drying treatment of cathode electrodes? Enhance Battery Performance

- How does the mechanical drive system of a Floating-Zone furnace impact crystal quality? Ensuring Homogeneity

- How does a vacuum heat treatment furnace compare to traditional heat treatment methods? Discover Precision and Quality Benefits

- What are the steps involved in a typical vacuum brazing treatment? Master the Process for Strong, Clean Joints