At its core, a vacuum brazing treatment is a multi-stage process that uses a controlled, flux-free environment to join components. The typical workflow involves meticulous cleaning of the parts, precise assembly with a filler metal, a highly controlled heating and cooling cycle inside a vacuum furnace, and finally, inspection and testing of the finished joint.

The success of vacuum brazing is less about the individual steps and more about the principle of absolute control. By eliminating atmospheric contaminants, the process enables a filler metal to bond with parent materials on a metallurgical level, creating exceptionally clean, strong, and stress-free joints.

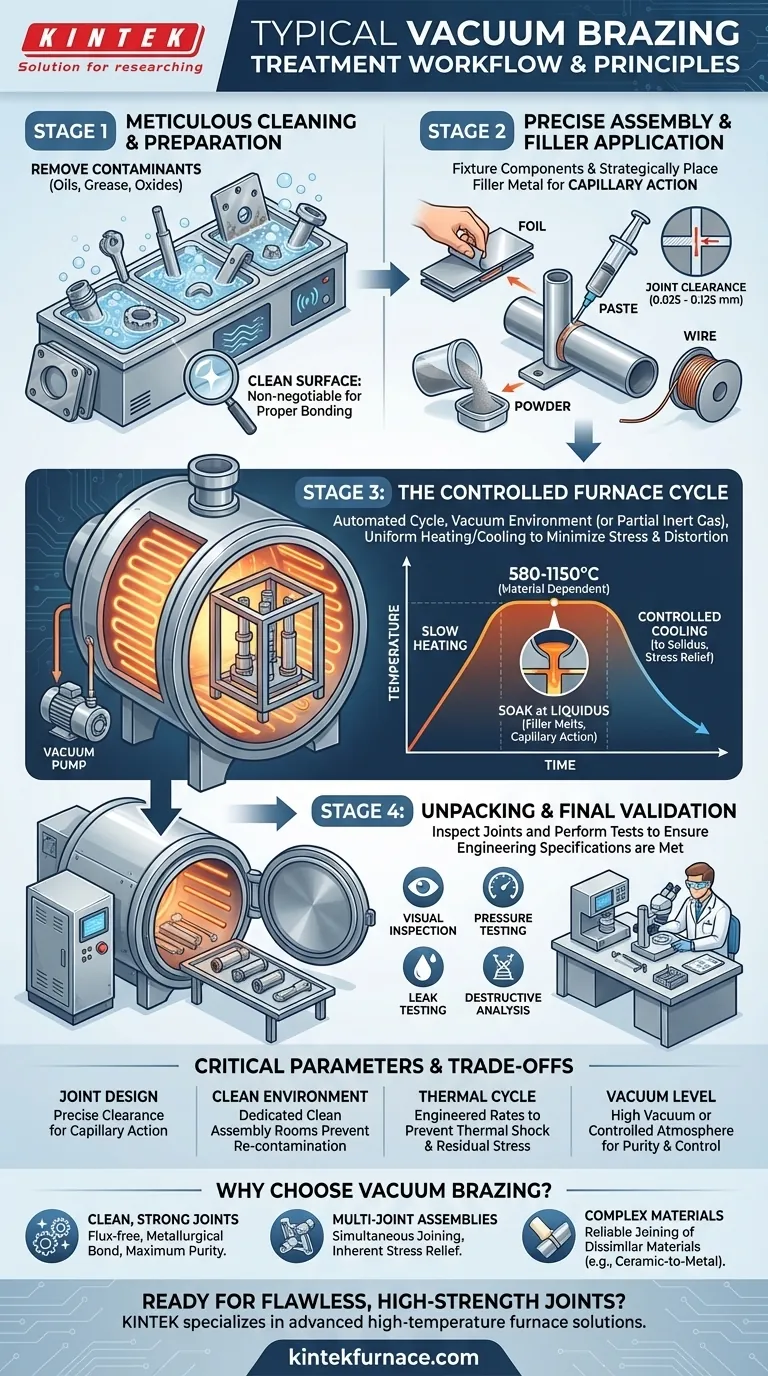

Deconstructing the Vacuum Brazing Workflow

Understanding each phase is crucial for appreciating why this process is chosen for high-performance applications. The workflow can be broken down into four distinct stages.

Step 1: Meticulous Cleaning and Preparation

Before anything enters the furnace, all components must be perfectly clean. The goal is to remove any surface contaminants, such as oils, grease, and especially oxides.

This cleaning is non-negotiable because the vacuum environment is designed to prevent oxides from forming, not remove existing ones. A clean surface ensures the molten filler metal can properly "wet" and bond with the parent materials.

Step 2: Precise Assembly and Filler Application

Once clean, the components are fixtured into their final assembly. The brazing filler metal is then strategically placed at or near the joints it needs to fill.

This filler metal can come in various forms, including foil, paste, powder, or wire. The choice depends on the joint design, materials, and specific application requirements.

Step 3: The Controlled Furnace Cycle

This is the heart of the process. The assembled parts are loaded onto furnace frames and placed inside the vacuum chamber. The cycle is typically automated and microprocessor-controlled.

First, a powerful vacuum is drawn to remove air and other reactive gases. The furnace then heats the assembly in a slow, controlled manner to the specified brazing temperature. This temperature varies significantly by material, from 580-620°C for aluminum alloys to 800-1150°C for steels and other high-temperature alloys.

The assembly is held at this peak temperature—above the filler metal's melting point (liquidus)—for a short duration. During this "soak," the filler metal melts and is drawn into the tight-fitting joints by capillary action.

Finally, the furnace begins a slow, controlled cooling cycle. This allows the filler metal to solidify (reaching its solidus temperature) and the entire assembly to cool uniformly, minimizing internal stresses and potential distortion.

Step 4: Unpacking and Final Validation

After the assembly has cooled completely, the furnace is brought back to atmospheric pressure and the parts are carefully unpacked.

The brazed joints undergo a thorough visual inspection. Depending on the component's requirements, further validation, such as pressure testing, leak testing, or destructive analysis, may be performed to ensure the joint meets all engineering specifications.

Understanding the Critical Parameters and Trade-offs

Simply following the steps is not enough. The reliability of a vacuum-brazed joint depends on mastering several critical variables that influence the outcome.

The Primacy of Joint Design and Clearance

Successful brazing relies on capillary action to pull the filler metal into the gap. For this to work, the joint clearance must be precisely controlled.

A typical clearance is between 0.025 mm and 0.125 mm (0.001" to 0.005"). Too small a gap prevents the filler from flowing in; too large a gap breaks the capillary effect and can result in voids or a weak joint.

The Importance of a Clean Environment

The need for cleanliness extends beyond the parts themselves. High-integrity brazing operations often use dedicated clean assembly rooms to prevent re-contamination before the parts enter the furnace.

Thermal Cycle Precision

The rates of heating and cooling are not arbitrary. They are carefully engineered to prevent thermal shock, distortion, and residual stress in the final assembly. This precise thermal management is one of the key advantages of vacuum furnace brazing.

Vacuum Level vs. Protective Atmosphere

While high vacuum is standard, some processes may introduce a partial pressure of an inert gas like argon. This can be used to suppress the vaporization of certain elements from the parent metals or filler alloy at high temperatures, providing an additional layer of process control.

Making the Right Choice for Your Project

Understanding the details of the process allows you to leverage its unique strengths for specific engineering goals.

- If your primary focus is joining complex or dissimilar materials (e.g., ceramic-to-metal): The precise, uniform thermal control of vacuum brazing minimizes stress and makes it one of the most reliable methods available.

- If your primary focus is creating multi-joint assemblies in a single step: The entire assembly can be heated and cooled as one, creating multiple, simultaneous joints that are inherently stress-relieved.

- If your primary focus is achieving maximum joint purity and strength: The flux-free environment prevents contamination, resulting in a clean, strong metallurgical bond that often rivals the strength of the parent materials.

By mastering each step and its underlying principles, you can use vacuum brazing to produce components with unparalleled reliability and performance.

Summary Table:

| Step | Key Actions | Critical Parameters |

|---|---|---|

| 1. Cleaning and Preparation | Remove oils, grease, and oxides; ensure contaminant-free surfaces | Cleanliness is non-negotiable for proper bonding |

| 2. Assembly and Filler Application | Fixture components; apply filler metal (foil, paste, powder, wire) | Joint clearance: 0.025-0.125 mm for capillary action |

| 3. Controlled Furnace Cycle | Load into vacuum furnace; heat to brazing temperature (e.g., 580-1150°C); hold and cool slowly | Temperature control, vacuum level, heating/cooling rates to prevent stress |

| 4. Unpacking and Validation | Inspect joints; perform tests (e.g., pressure, leak) | Visual and engineering specification checks |

Ready to achieve flawless, high-strength joints with vacuum brazing? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your project's reliability and performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments