In essence, a vacuum furnace is a highly controlled environment. Unlike traditional heat treatment methods that heat parts in the open air or a gaseous atmosphere, a vacuum furnace removes the atmosphere from a sealed chamber before applying heat. This fundamental difference in approach integrates heating, soaking, and quenching into a single, automated, and contamination-free process, yielding significant advantages in material quality and process control.

The choice between vacuum and traditional heat treatment is not merely about equipment; it is a strategic decision. Traditional methods prioritize throughput and cost for less-critical parts, while vacuum furnaces prioritize precision, material integrity, and surface perfection for high-value components.

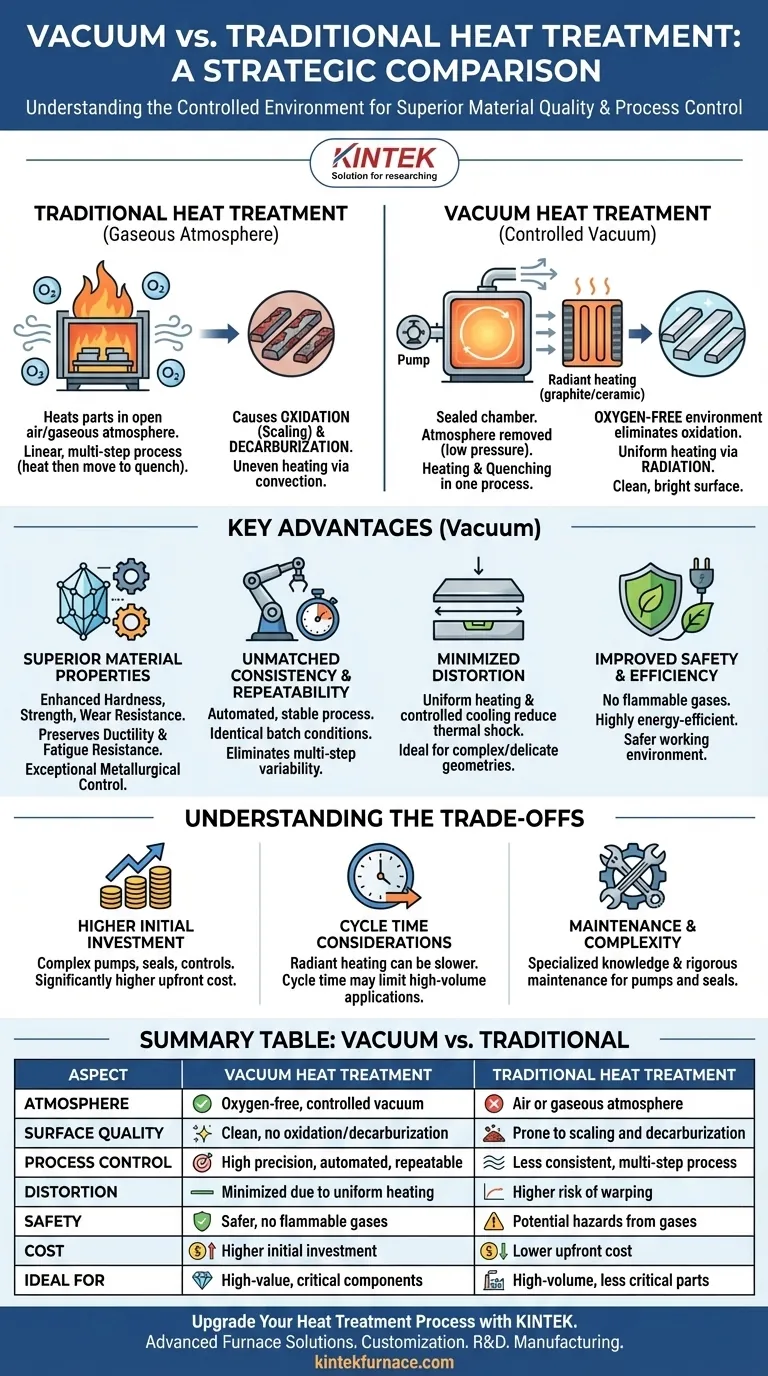

The Core Difference: Controlling the Atmosphere

The primary distinction between these two technologies lies in how they manage the environment surrounding the part during the heating cycle. This single factor drives all subsequent differences in quality, efficiency, and safety.

How a Traditional Furnace Works

Traditional furnaces typically heat parts in an environment containing oxygen and other reactive gases. This is a linear process where parts are heated in one piece of equipment and then physically moved to another for quenching (rapid cooling).

This exposure to the atmosphere at high temperatures inevitably leads to chemical reactions on the part's surface, such as oxidation (scaling) and decarburization (the loss of carbon content from steel).

How a Vacuum Furnace Works

A vacuum furnace is a sealed vessel that first uses a pumping system to evacuate nearly all of the air, creating a low-pressure environment. Only then are the heating elements, typically made of graphite or ceramic, energized.

Heat is transferred primarily through radiation, which ensures uniform heating without the unevenness that can be caused by convection currents in a traditional furnace. Cooling (quenching) is also performed inside the chamber, often by backfilling with a high-purity inert gas like nitrogen or argon.

The Impact of an Oxygen-Free Environment

By removing oxygen, vacuum heat treatment eliminates the root cause of high-temperature oxidation. This means parts emerge from the furnace clean, bright, and free from scale.

This "clean" processing preserves the integrity of the part's surface, which is critical for components requiring high fatigue life or specific surface finishes.

Key Advantages for Product and Process

The controlled environment of a vacuum furnace translates directly into measurable improvements for both the final product and the manufacturing workflow.

Superior Material Properties

The precise, uniform heating and cooling cycles allow for exceptional metallurgical control. This enhances critical properties such as hardness, strength, and wear resistance while preserving others like ductility and fatigue resistance.

Unmatched Consistency and Repeatability

Because the entire process is automated within a sealed chamber, it is highly stable and repeatable. Every batch can be processed under the exact same conditions, eliminating the variability common in traditional, multi-step methods.

Minimized Distortion

Uniform heating and controlled, often slower, cooling cycles reduce the thermal shock experienced by the part. This significantly minimizes warping and distortion, which is especially important for complex or delicate geometries.

Improved Safety and Efficiency

Vacuum furnaces eliminate the need for flammable or explosive atmospheres, creating a much safer working environment. They are also highly energy-efficient, as there is no need for weekend idling and thermal efficiency is high in the vacuum environment.

Understanding the Trade-offs

While the benefits are substantial, vacuum technology is not a universal solution. Acknowledging its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces are complex systems involving pumps, seals, and sophisticated controls. This results in a significantly higher upfront capital cost compared to simpler, traditional atmosphere furnaces.

Cycle Time Considerations

In a pure vacuum, heat transfer by radiation can be slower than the convective heating of a traditional furnace, especially for densely packed loads. While modern furnaces mitigate this with inert gas backfilling to assist convection, cycle time can still be a limiting factor for certain high-volume applications.

Maintenance and Complexity

The vacuum system, including its pumps and seals, requires specialized knowledge and a rigorous maintenance schedule to ensure it operates correctly and maintains a low-pressure environment.

Making the Right Choice for Your Application

The best method depends entirely on your specific requirements for the finished part, your production volume, and your budget.

- If your primary focus is high-volume, low-cost production where surface finish is not critical: Traditional atmosphere furnaces often provide the most cost-effective solution.

- If your primary focus is precision, superior surface finish, and repeatable material properties: Vacuum heat treatment is the definitive choice for critical components in aerospace, medical, or tool steel applications.

- If your primary focus is processing high-purity or highly reactive metals: The contaminant-free environment of a vacuum furnace is an absolute necessity.

- If your primary focus is safety and environmental compliance: The self-contained, pollution-free nature of vacuum furnaces eliminates flammable gases and harmful emissions.

Choosing the right heat treatment technology is a direct investment in the final quality and long-term reliability of your components.

Summary Table:

| Aspect | Vacuum Heat Treatment | Traditional Heat Treatment |

|---|---|---|

| Atmosphere | Oxygen-free, controlled vacuum | Air or gaseous atmosphere |

| Surface Quality | Clean, no oxidation or decarburization | Prone to scaling and decarburization |

| Process Control | High precision, automated, repeatable | Less consistent, multi-step process |

| Distortion | Minimized due to uniform heating | Higher risk of warping |

| Safety | Safer, no flammable gases | Potential hazards from gases |

| Cost | Higher initial investment | Lower upfront cost |

| Ideal For | High-value, critical components | High-volume, less critical parts |

Upgrade Your Heat Treatment Process with KINTEK

Are you striving for superior material integrity, precise control, and contamination-free results in your laboratory? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure our furnaces meet your exact experimental requirements, enhancing efficiency and reliability.

Don't settle for less—contact us today to discuss how our solutions can transform your heat treatment processes. Reach out now via our contact form and let KINTEK help you achieve unparalleled quality and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion