At its core, a vacuum brazing furnace provides a superior method for creating strong, clean, and dimensionally stable metal assemblies. It achieves this by performing the joining process inside a high-vacuum environment, which eliminates atmospheric contamination and allows for extremely precise thermal control, preventing the oxidation and part distortion common with other methods.

The fundamental advantage of vacuum brazing is not just the joint itself, but the pristine, controlled environment in which it is created. This environment is the key to achieving unparalleled quality, joining complex materials, and ensuring a repeatable process for high-performance applications.

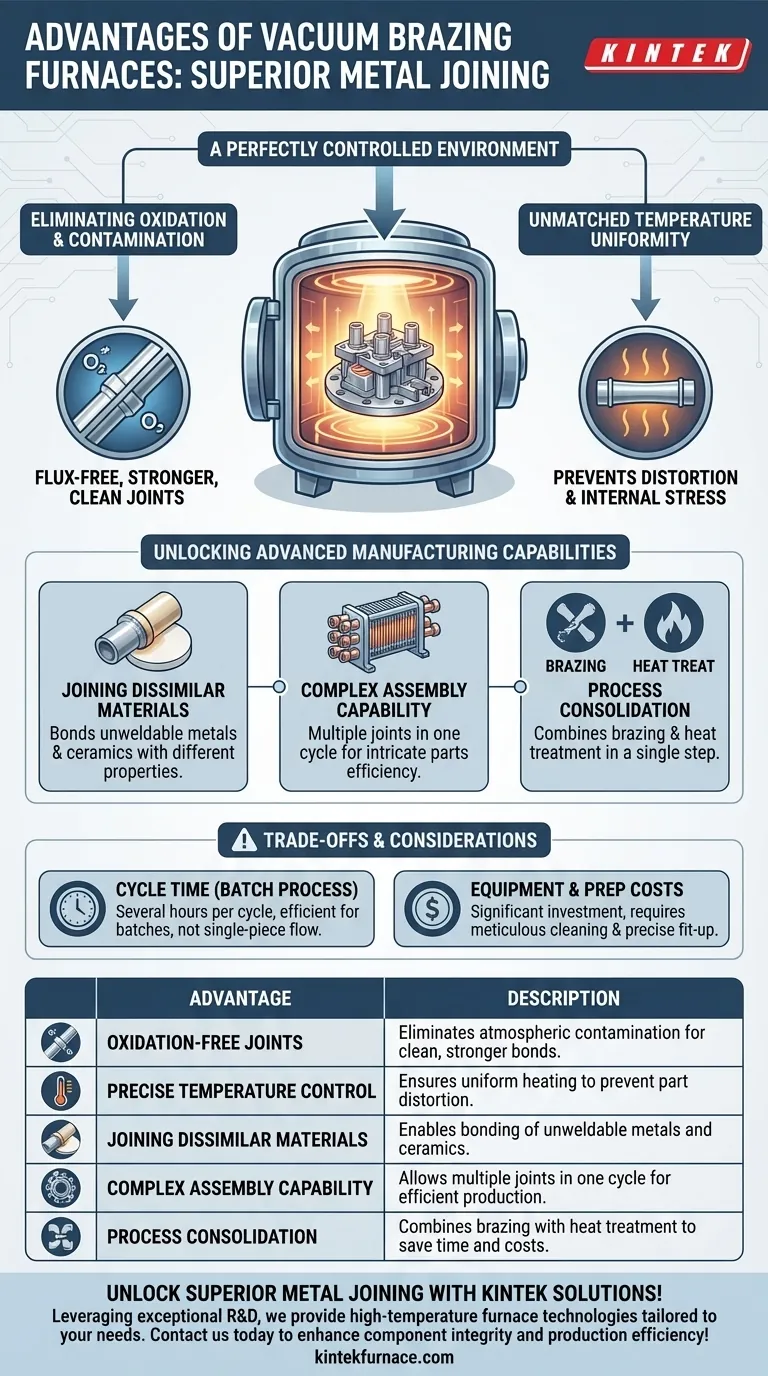

The Core Advantage: A Perfectly Controlled Environment

The "vacuum" in vacuum brazing is the source of its primary benefits. By removing air and other gases, the furnace creates an ideal state for joining metals that is impossible to achieve in open-air processes.

Eliminating Oxidation and Contamination

In traditional brazing or welding, oxygen in the air rapidly forms oxides on the hot metal surfaces. These oxides inhibit the flow of the filler metal and can become trapped in the joint, creating weak points.

Vacuum brazing completely removes this variable. By operating in a near-perfect vacuum, there is no oxygen to create oxides. This results in exceptionally clean, flux-free joints that are inherently stronger and more reliable.

Achieving Unmatched Temperature Uniformity

A vacuum furnace heats the entire component assembly slowly and uniformly through radiation. This is fundamentally different from welding, which applies intense, localized heat with a torch or arc.

This uniform heating eliminates thermal gradients across the part. As a result, internal stresses are not created, and sensitive or complex parts are not warped or distorted. This precision is critical for components with tight dimensional tolerances.

Unlocking Advanced Manufacturing Capabilities

The controlled environment of a vacuum furnace opens the door to engineering solutions that would otherwise be impractical or impossible.

Joining Dissimilar and Unweldable Materials

The gentle, uniform heating cycle allows for the successful joining of materials with different thermal expansion rates, such as copper to steel or even metals to ceramics.

Furthermore, many high-strength alloys used in aerospace and medical applications are considered "unweldable" with conventional techniques. Vacuum brazing is often the only viable method for joining them.

Creating Complex Assemblies with Multiple Joints

Because the entire furnace is the heat source, there is no limit to the number of joints that can be made in a single cycle.

Engineers can design complex assemblies with dozens or even hundreds of joints, place the filler metal, and braze the entire structure at once. This offers a massive efficiency gain for producing intricate parts like heat exchangers or sensor assemblies.

Combining Brazing and Heat Treatment

The furnace's programmable heating and cooling cycles can be designed to perform metallurgical heat treatments—such as hardening, annealing, or stress-relieving—within the same process run.

This consolidation of steps, known as "one-shot" processing, saves significant time, energy, and material handling costs, streamlining the entire production workflow.

Understanding the Trade-offs

While powerful, vacuum brazing is not a universal solution. Understanding its limitations is key to using it effectively.

Cycle Time and Batch Processing

A vacuum furnace cycle involves multiple stages: loading, pumping the chamber down to vacuum, heating, brazing, cooling, and venting. This process can take several hours.

This makes it inherently a batch process. It is extremely efficient for running many parts at once but is less suited for a high-volume, single-piece-flow production line where speed per part is the primary metric.

Equipment and Preparation Costs

Vacuum furnaces represent a significant capital investment. They are complex machines that require specialized maintenance.

The process is also less forgiving of poor preparation. Parts must be meticulously cleaned and assembled with precise joint gaps to ensure the capillary action of the braze alloy works correctly. Any contaminants can ruin the entire batch.

Making the Right Choice for Your Application

Choosing a joining process requires aligning its capabilities with your primary goal.

- If your primary focus is component integrity and precision: Vacuum brazing is the superior choice for creating stress-free, distortion-free assemblies, especially for complex or thin-walled parts.

- If your primary focus is joining dissimilar or advanced materials: This process unlocks the ability to join materials that cannot be welded or have different thermal properties.

- If your primary focus is scalable production quality: Vacuum brazing delivers unmatched repeatability and allows you to consolidate brazing and heat treatment into a single, automated, and highly efficient step.

Ultimately, adopting vacuum brazing is a strategic decision for applications where the final quality, strength, and precision of the component cannot be compromised.

Summary Table:

| Advantage | Description |

|---|---|

| Oxidation-Free Joints | Eliminates atmospheric contamination for clean, flux-free, and stronger bonds. |

| Precise Temperature Control | Ensures uniform heating to prevent part distortion and internal stresses. |

| Joining Dissimilar Materials | Enables bonding of unweldable metals and ceramics with different thermal properties. |

| Complex Assembly Capability | Allows multiple joints in one cycle for efficient production of intricate parts. |

| Process Consolidation | Combines brazing with heat treatment in a single step to save time and costs. |

Unlock superior metal joining with KINTEK's advanced vacuum brazing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace technologies tailored to your needs. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Contact us today to enhance your component integrity and production efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering